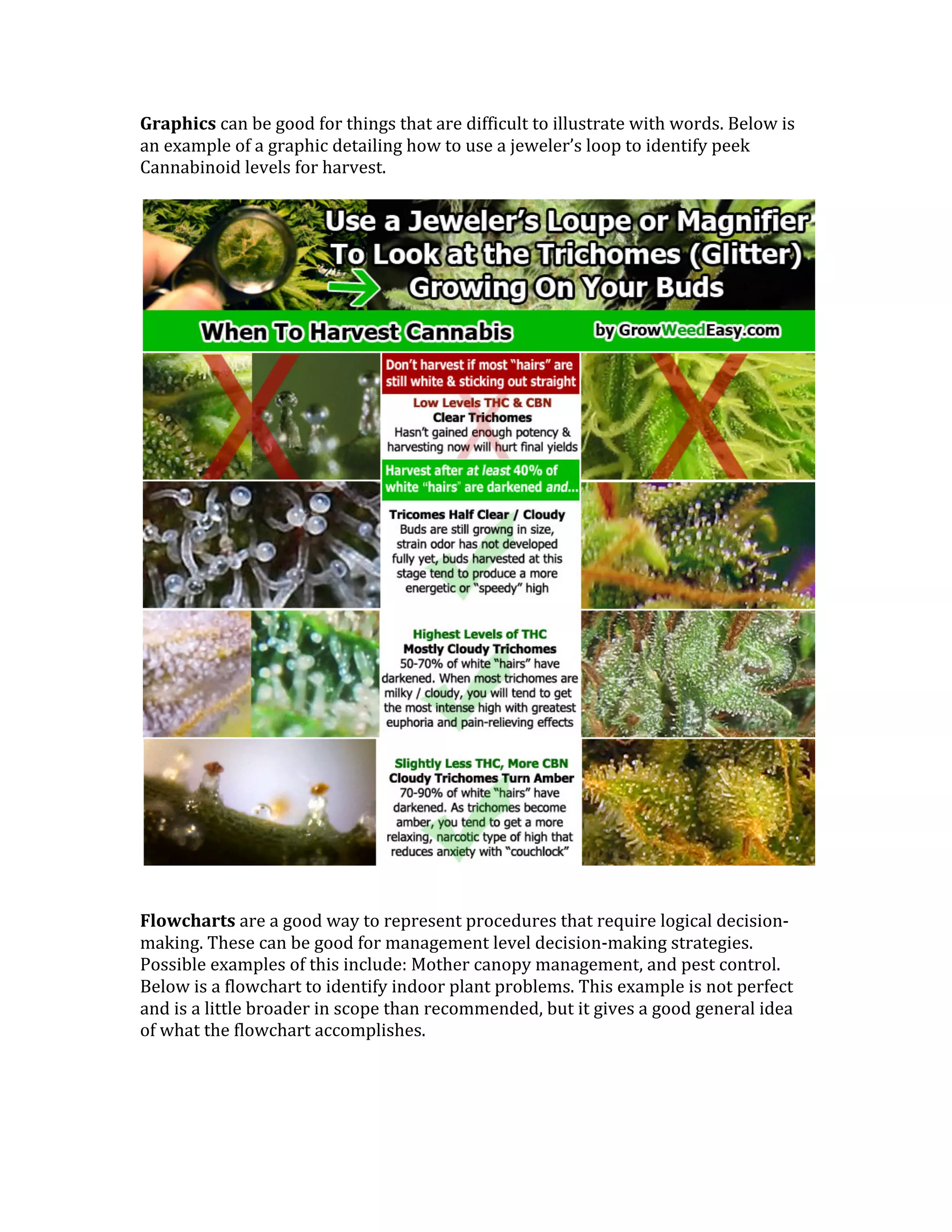

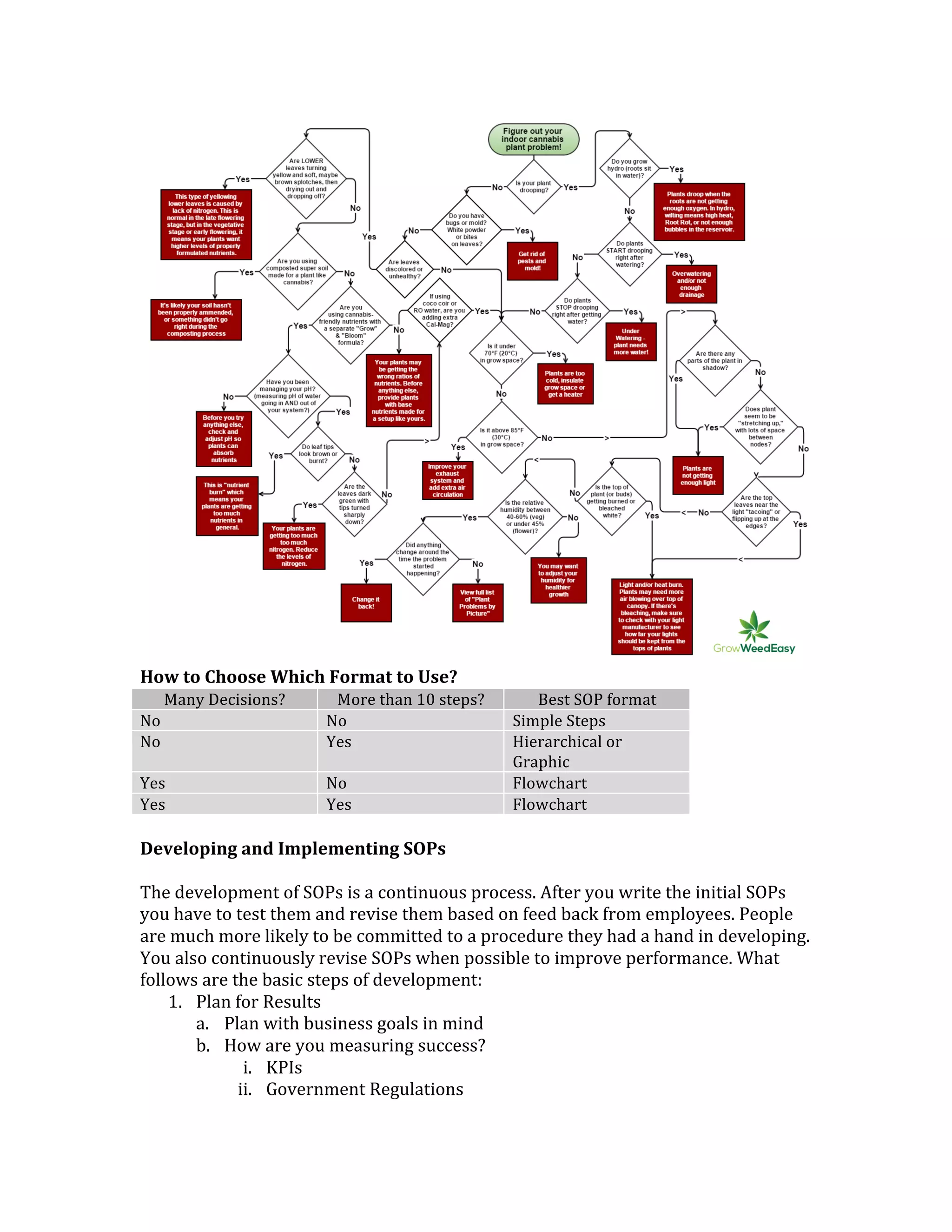

This document provides guidance on developing standard operating procedures (SOPs) for cannabis cultivation. It discusses defining systems, procedures, and steps, and provides examples of each. Systems refer to broad cultivation areas, procedures are specific tasks within each system, and steps are the individual instructions. The document recommends choosing simple steps, hierarchical steps, flowcharts or graphics as the SOP format depending on the complexity of the process. It outlines the basic process for developing, reviewing, testing, implementing and training employees on new SOPs.

![Developing

SOPs

Defining

Systems,

Procedures,

and

Steps:

In

development

of

SOPs

you

want

to

build

a

document

to

train

workers

to

do

procedures

consistently

and

accurately.

This

ensures

a

consistently

high

quality

product.

In

the

development

of

SOPs

we

think

of

three

levels:

Systems,

Procedures,

and

Steps.

Examples

of

these

in

a

Cannabis

context

are

given

below:

Systems:

• Propagation

• Vegetative

Growth

• Flowering

• Harvest/Dry

Cure

• Soil

Mixing

• Water

Irrigation

and

Fertigation

Systems

• QC

and

Analytics

Procedures

(examples

from

Propagation):

• Seed

Germination

• Seedling

Transplantation

• Mother

Plant

Canopy

Management

• Clone

Cutting

• Establishing

Cuttings

in

Growth

Media

Steps

(from

draft

paper

towel

seed

germination

SOP)

1. Place

seeds

to

be

germinated

in

clean

glass

beaker

2. Fill

beaker

with

water

and

soak

seeds

for

at

least

12

hours

but

not

more

then

24

3. Drain

off

water

from

beaker

containing

seeds

4. Using

different

water

moisten

paper

towel

5. Place

seeds

on

moist

paper

towel

6. Fold

paper

towel

to

give

seeds

a

dark

environment,

place

on

grated

plate

to

allow

for

drainage.

[Picture

needed]

7. Mark

paper

towel

with

lot

number

8. Place

plate

in

incubator

set

to

70-‐90°

F

(strain

specific)

9. Water

plate

regularly

to

keep

the

environment

moist

10. Observe

for

first

signs

of

white

sprout

[picture]

11. Sprouted

seeds

should

be

marked

and

reported

for

transplant

to

12

oz

container

with

cocos.

Sometimes

simple

step

SOPs

are

not

going

to

be

the

best

way

to

explain

a

procedure.

Hierarchical

step

SOPs

are

for

tasks

that

are

more

intricate

and

likely

include

sub-‐steps

clarifying

technique.

Clone

cutting

and

seedling

transplantation

are

possible

examples

of

this.](https://image.slidesharecdn.com/a2aec16c-cfc7-4a5a-a141-225c43ba6956-160329034809/75/Developing-SOPs-1-2048.jpg)