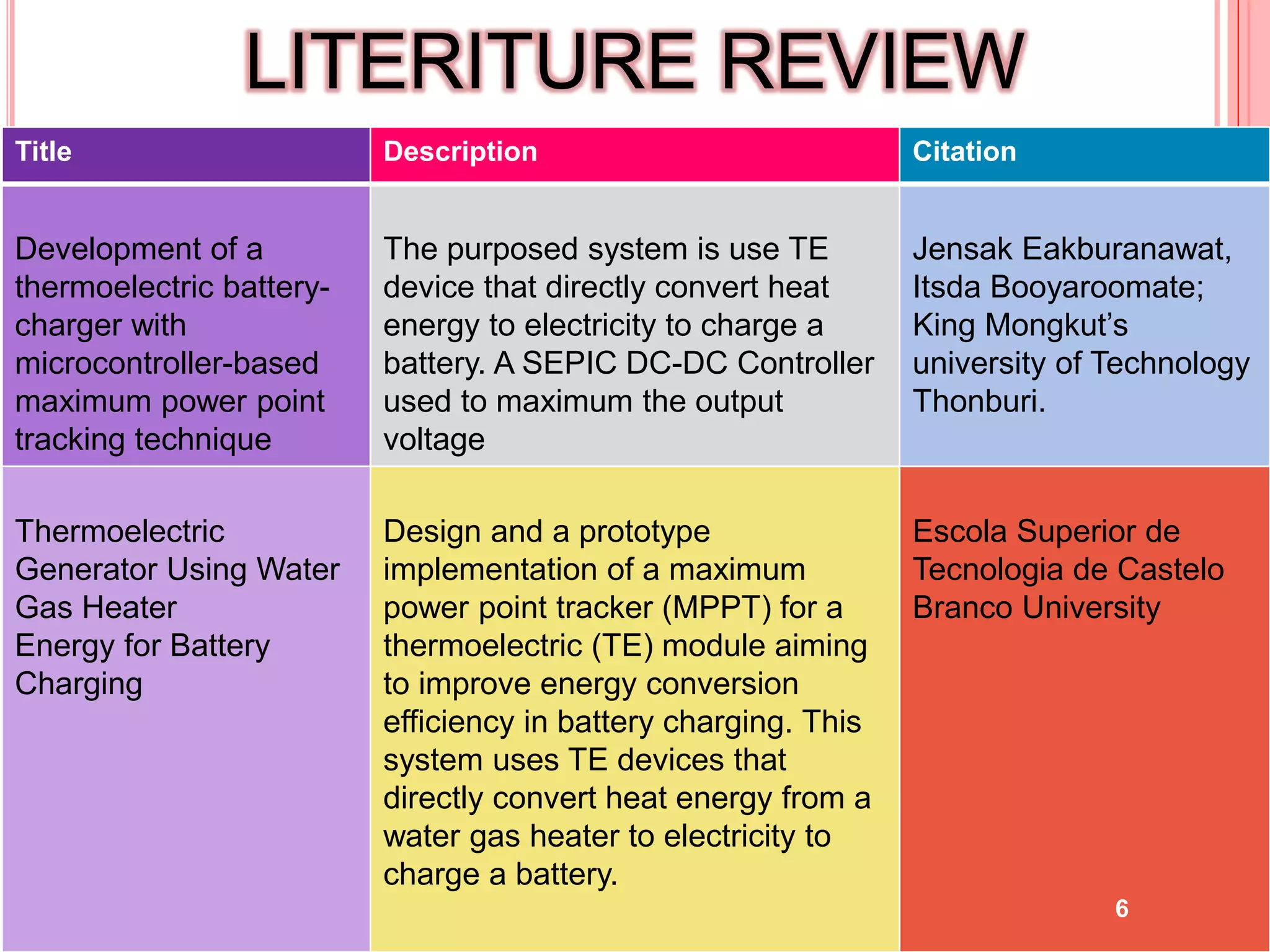

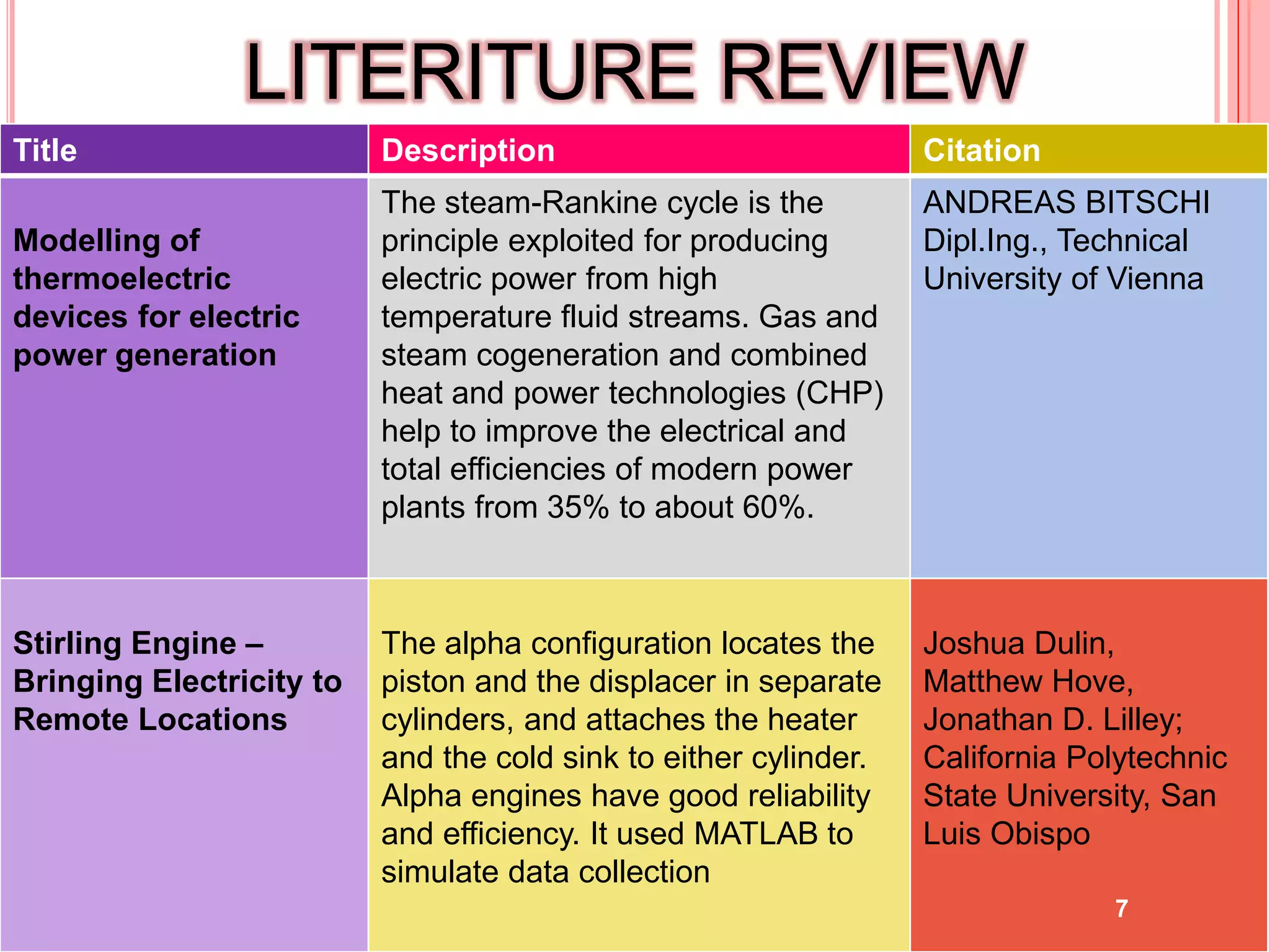

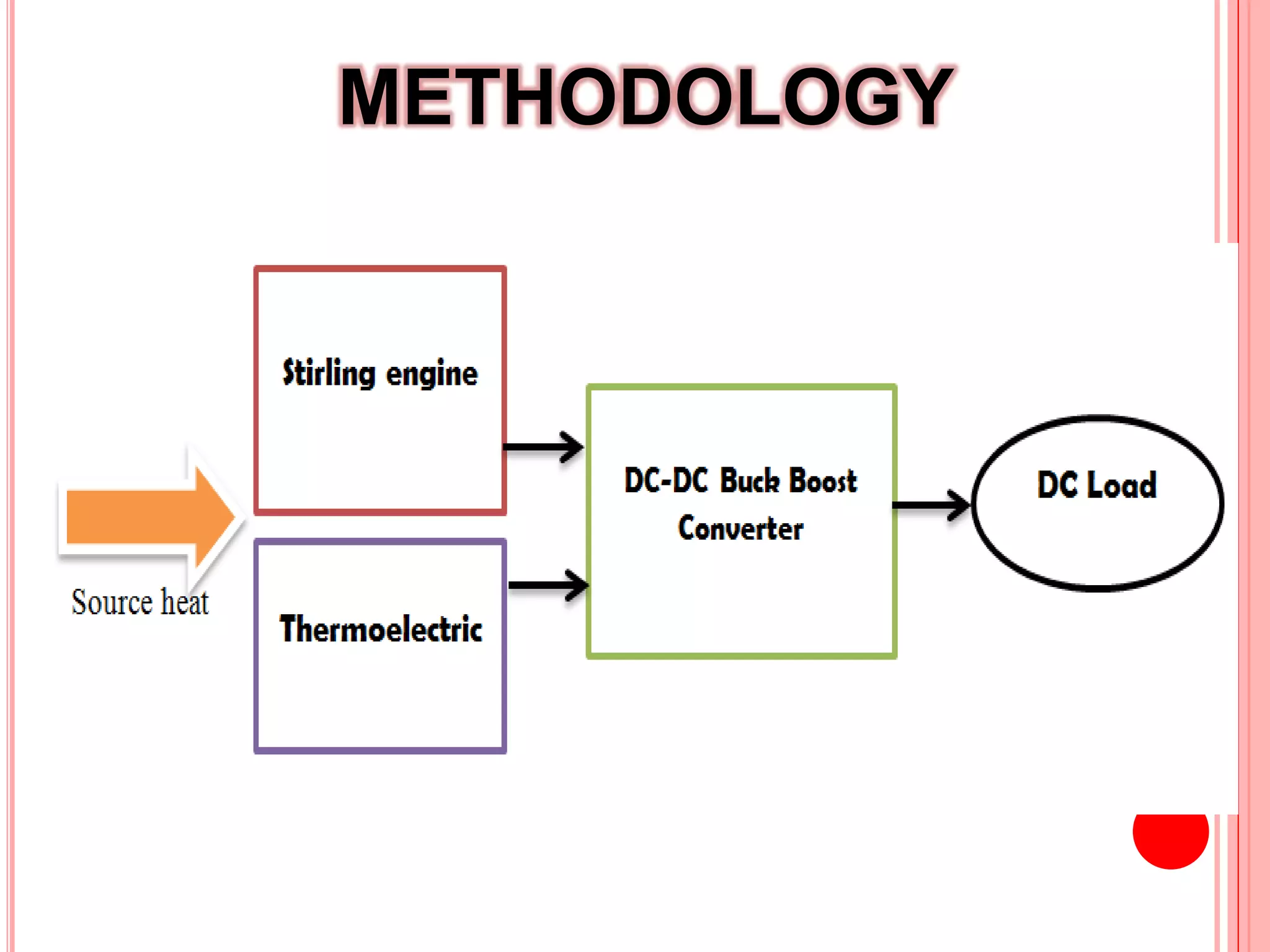

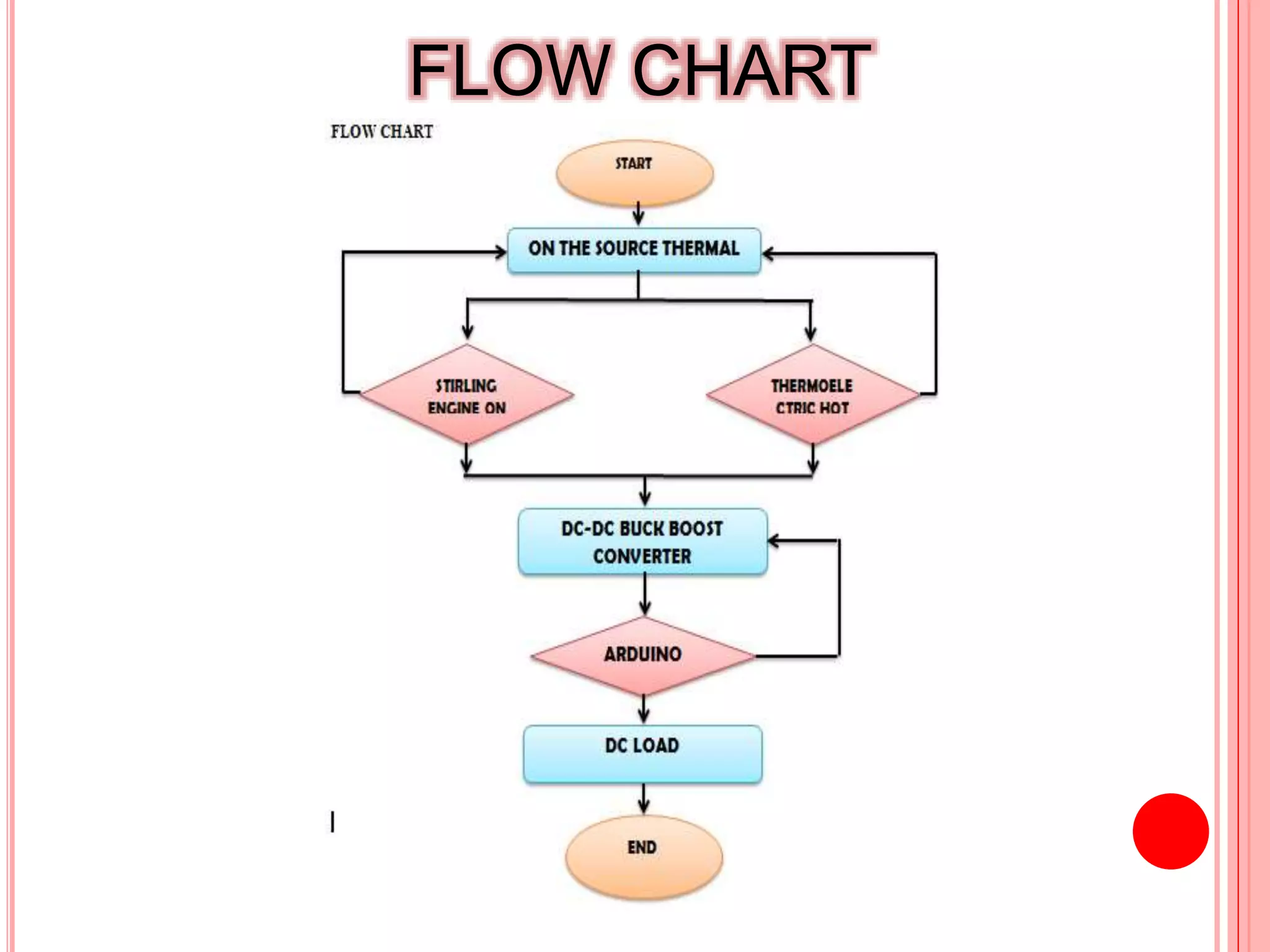

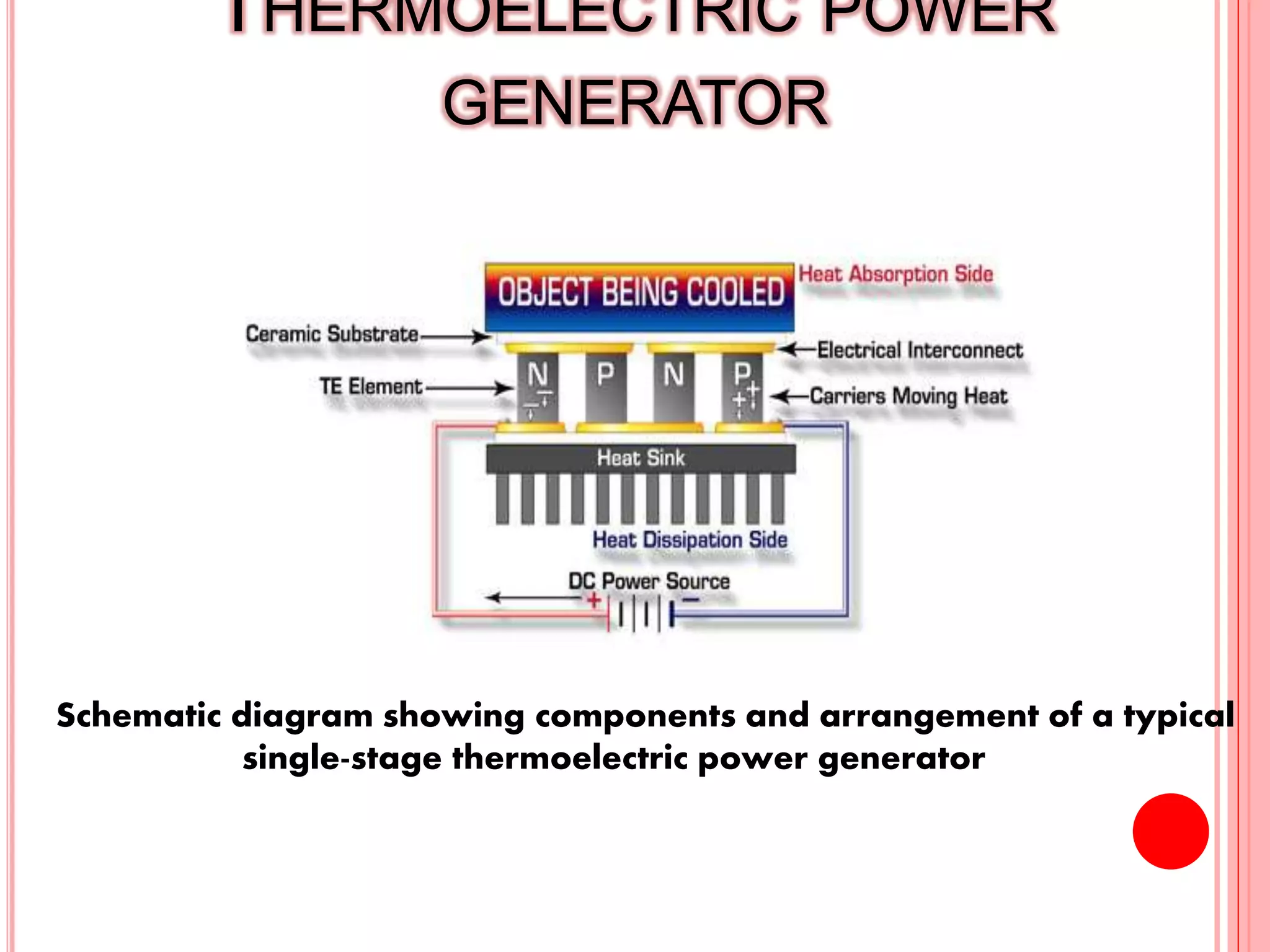

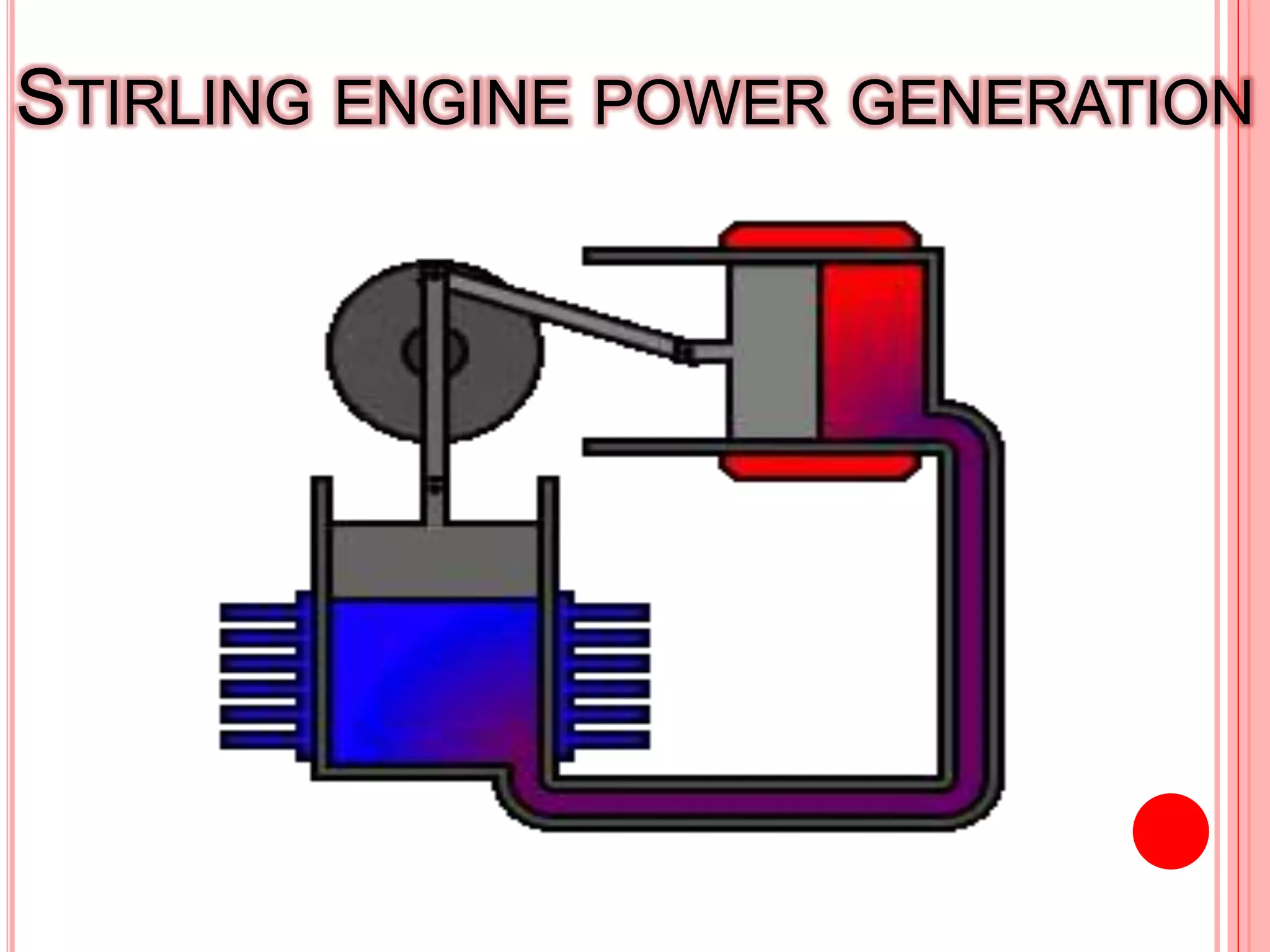

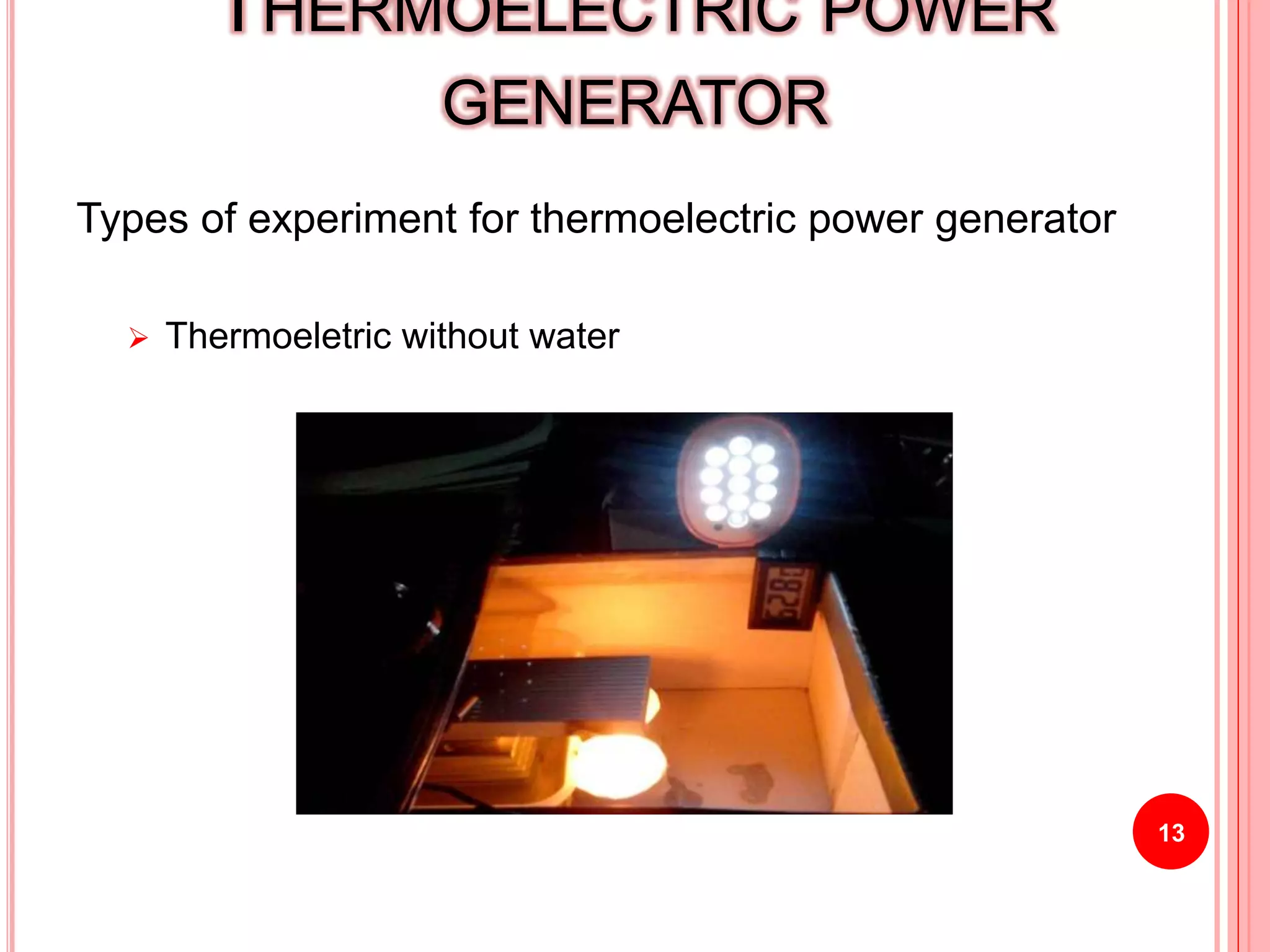

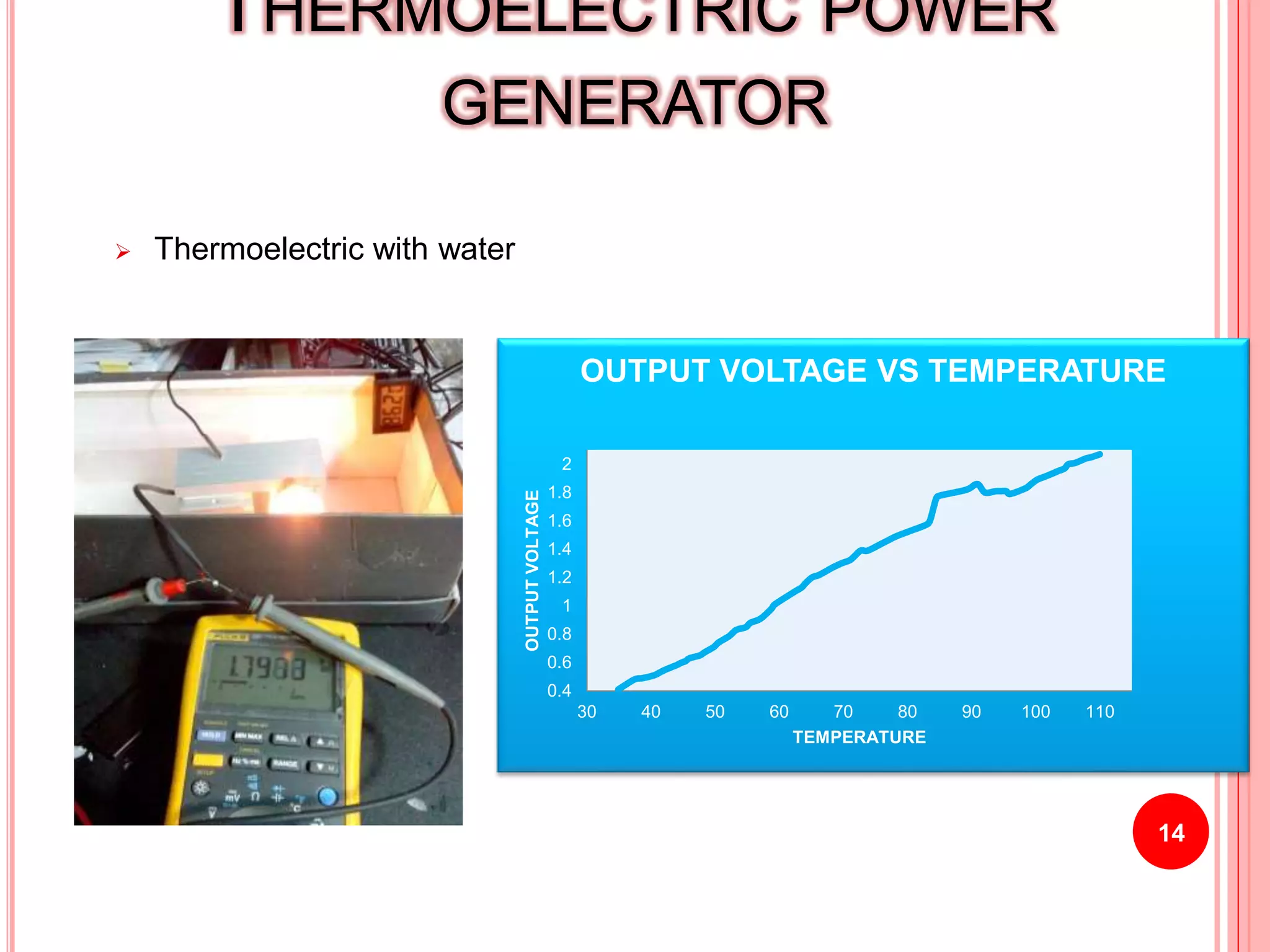

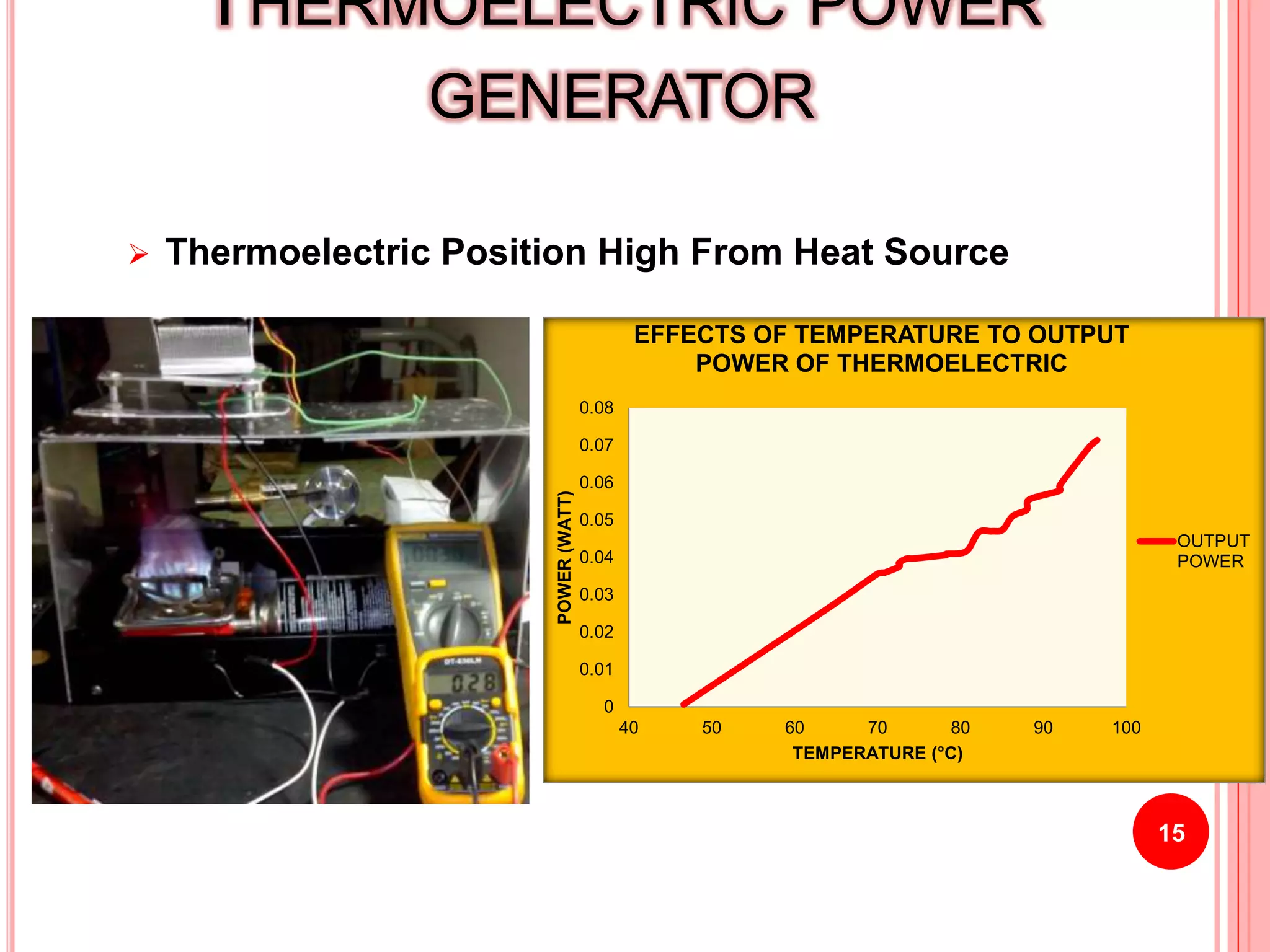

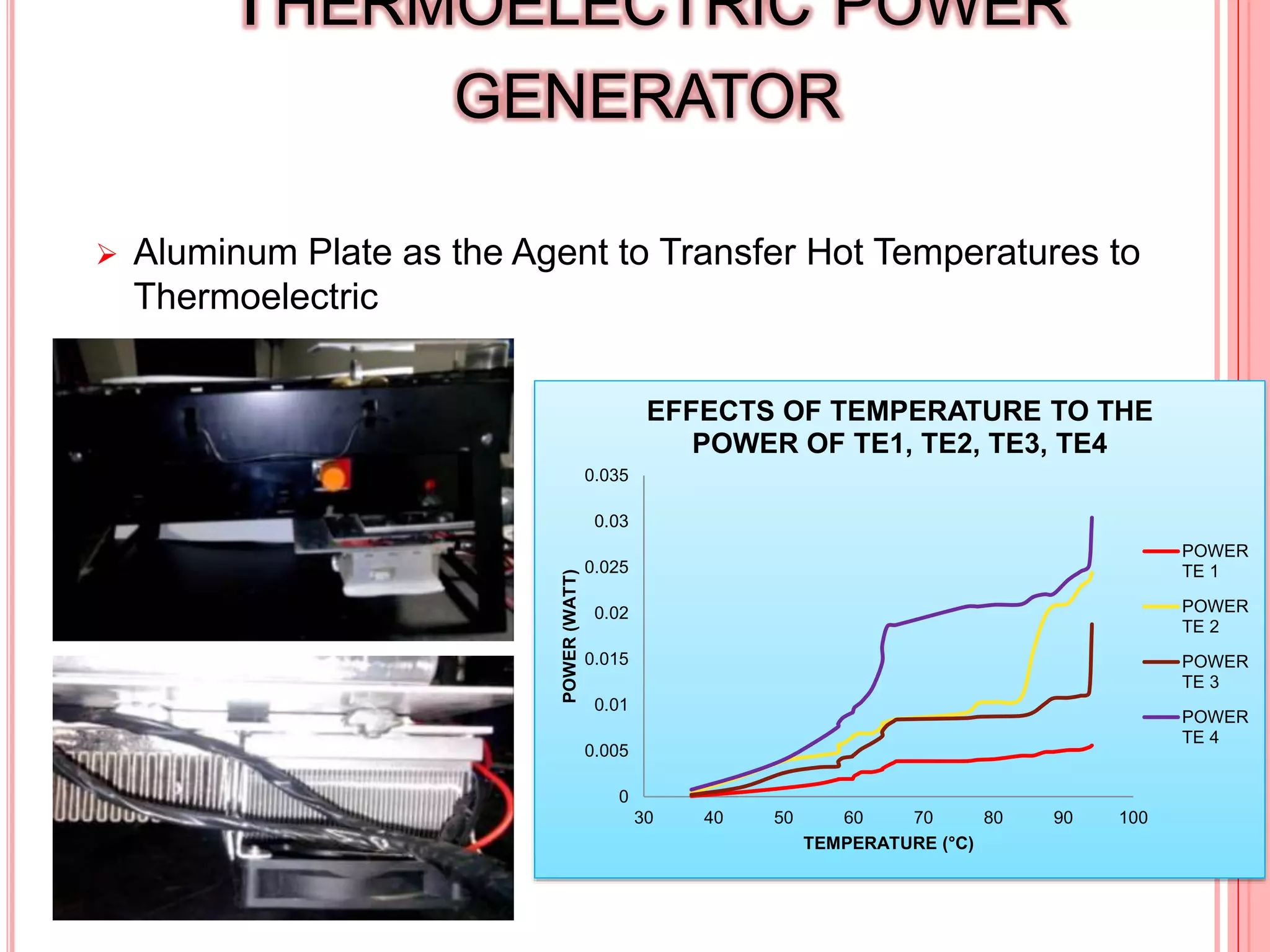

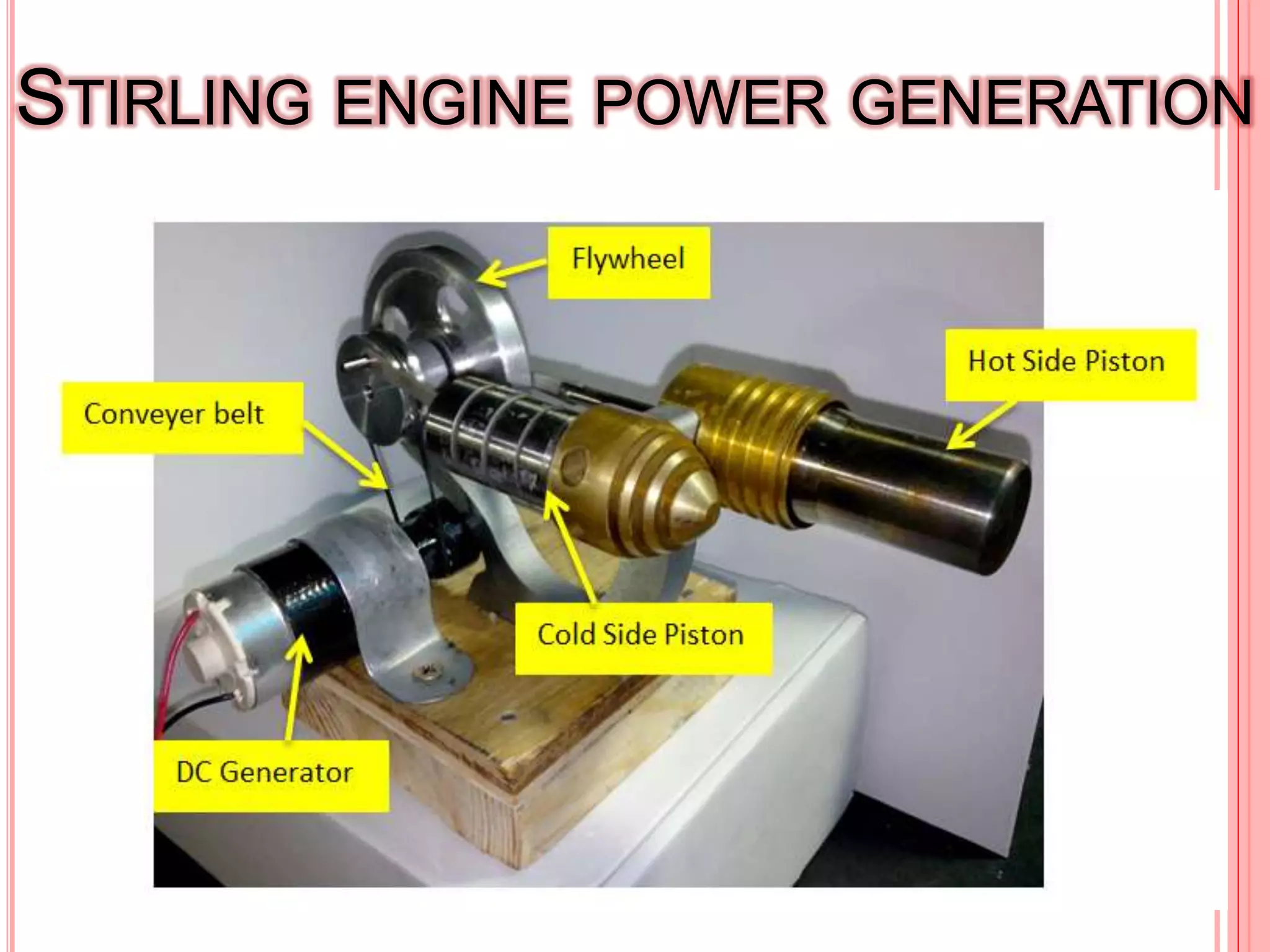

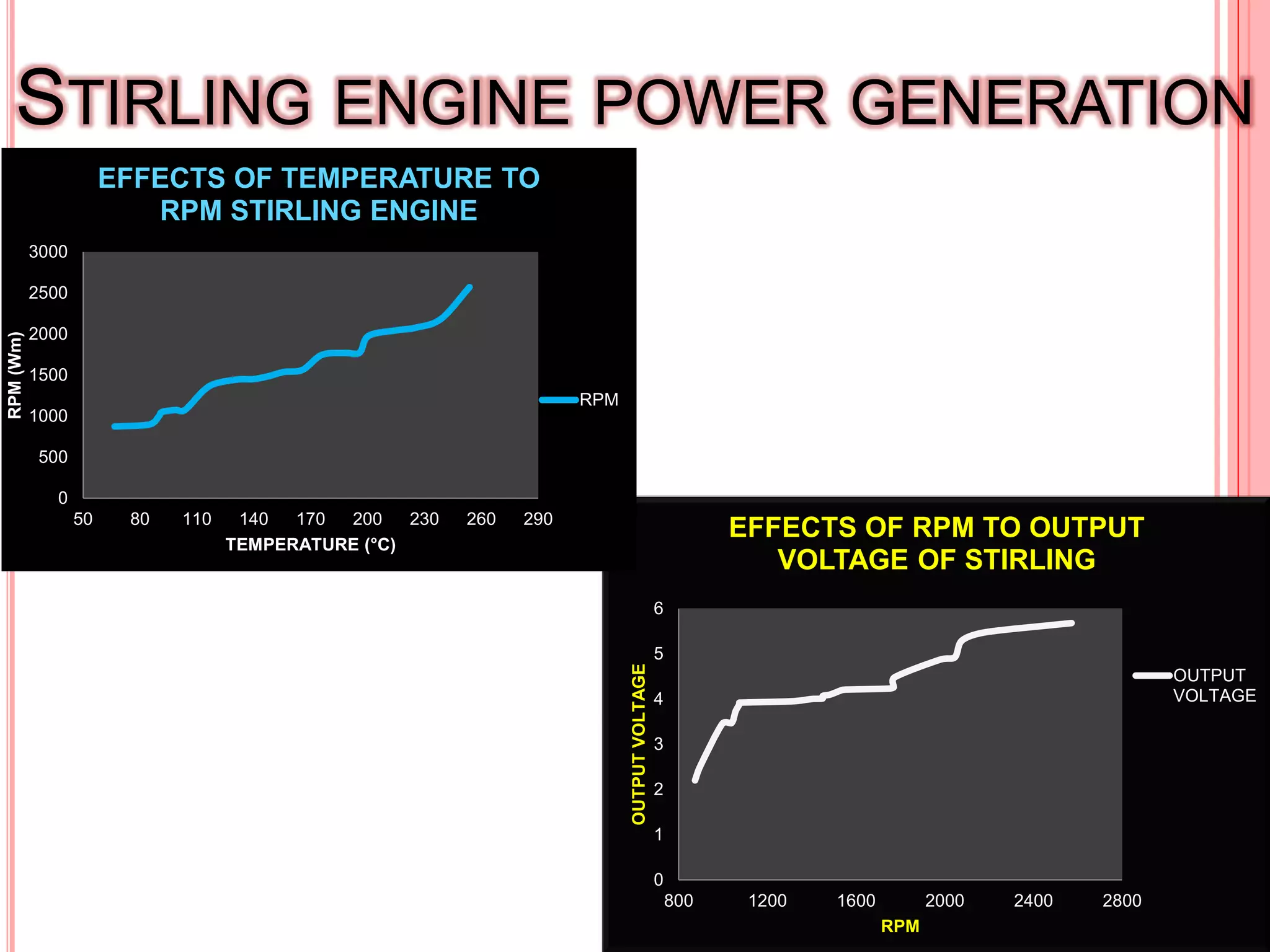

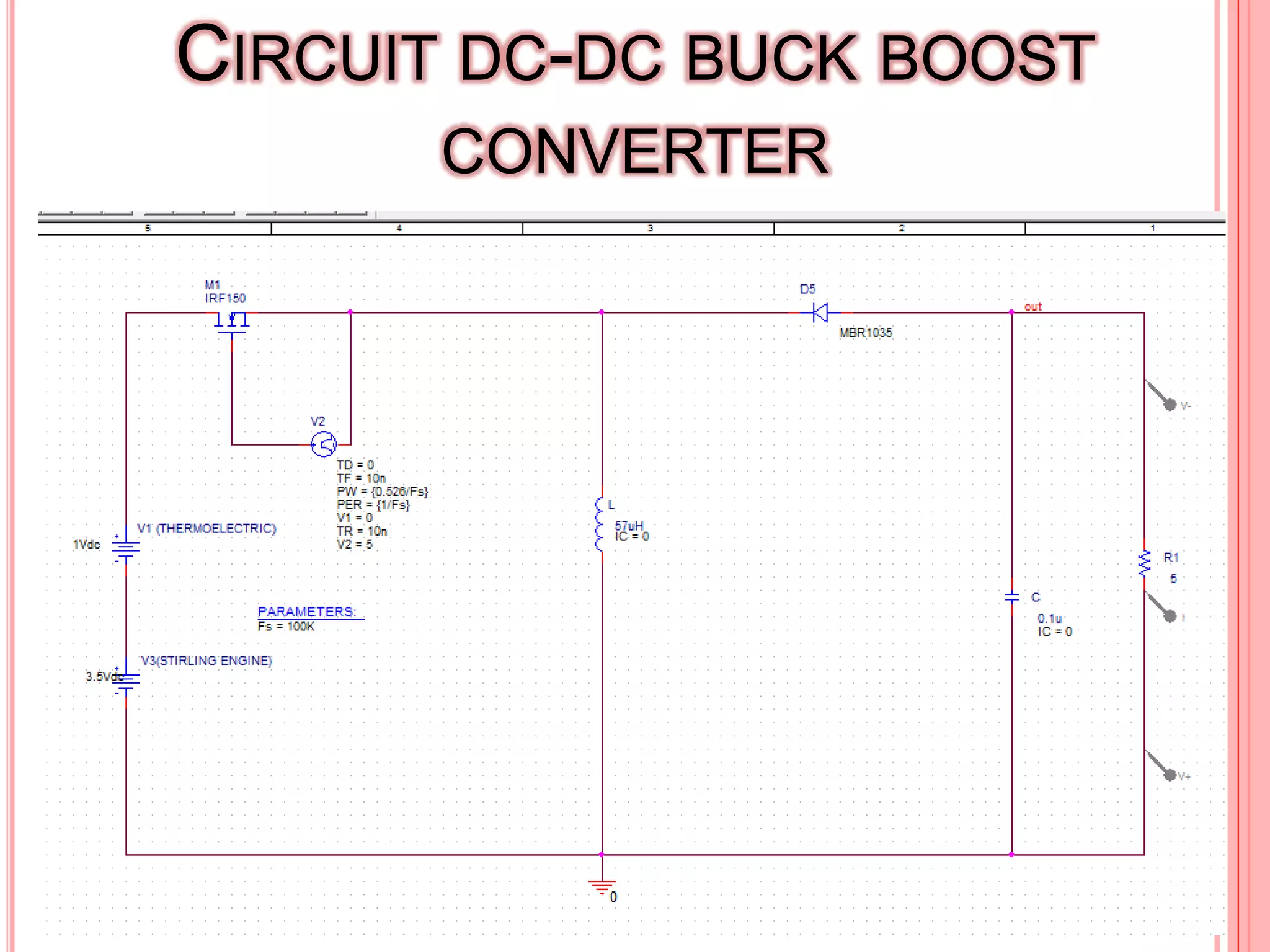

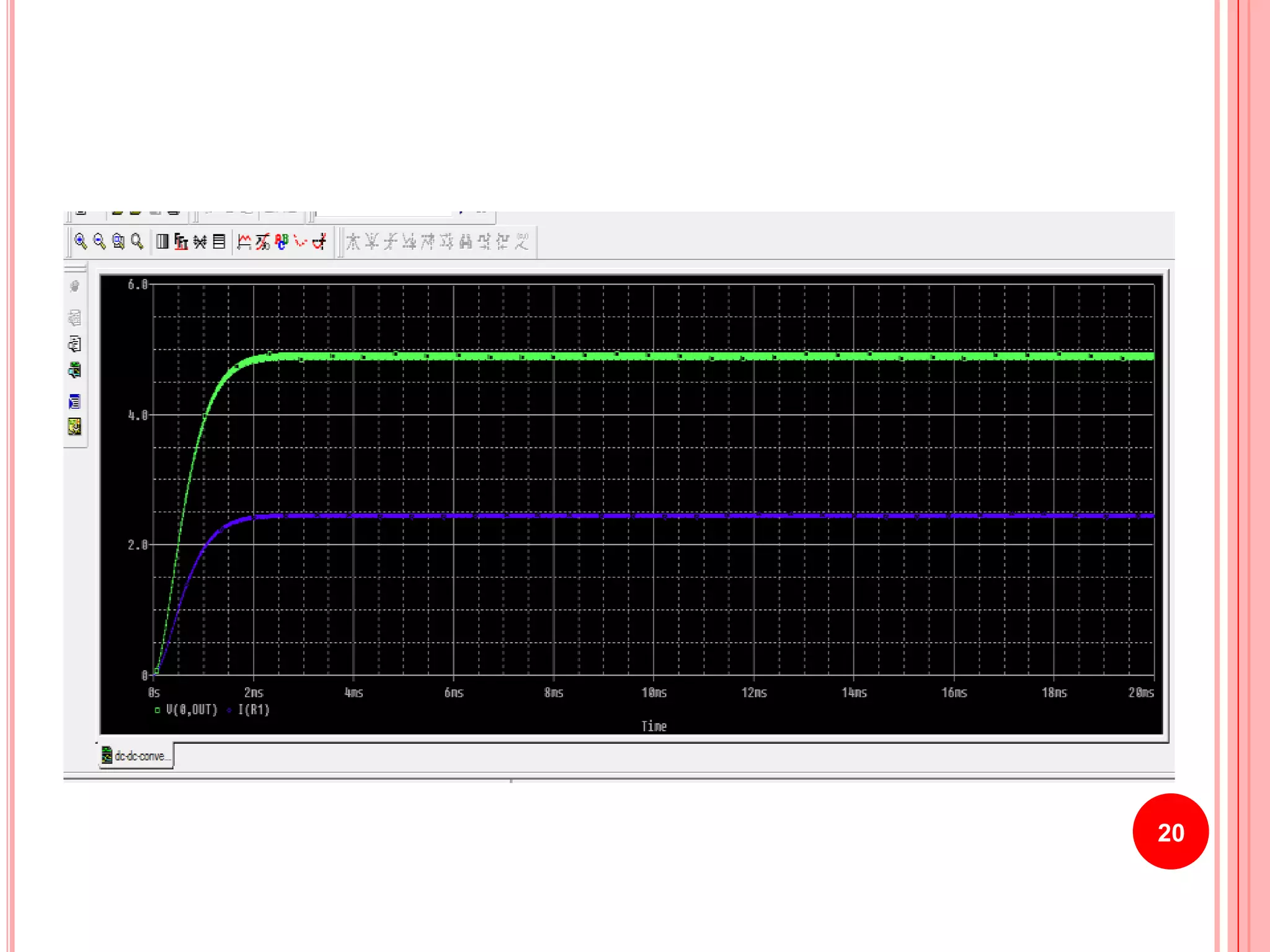

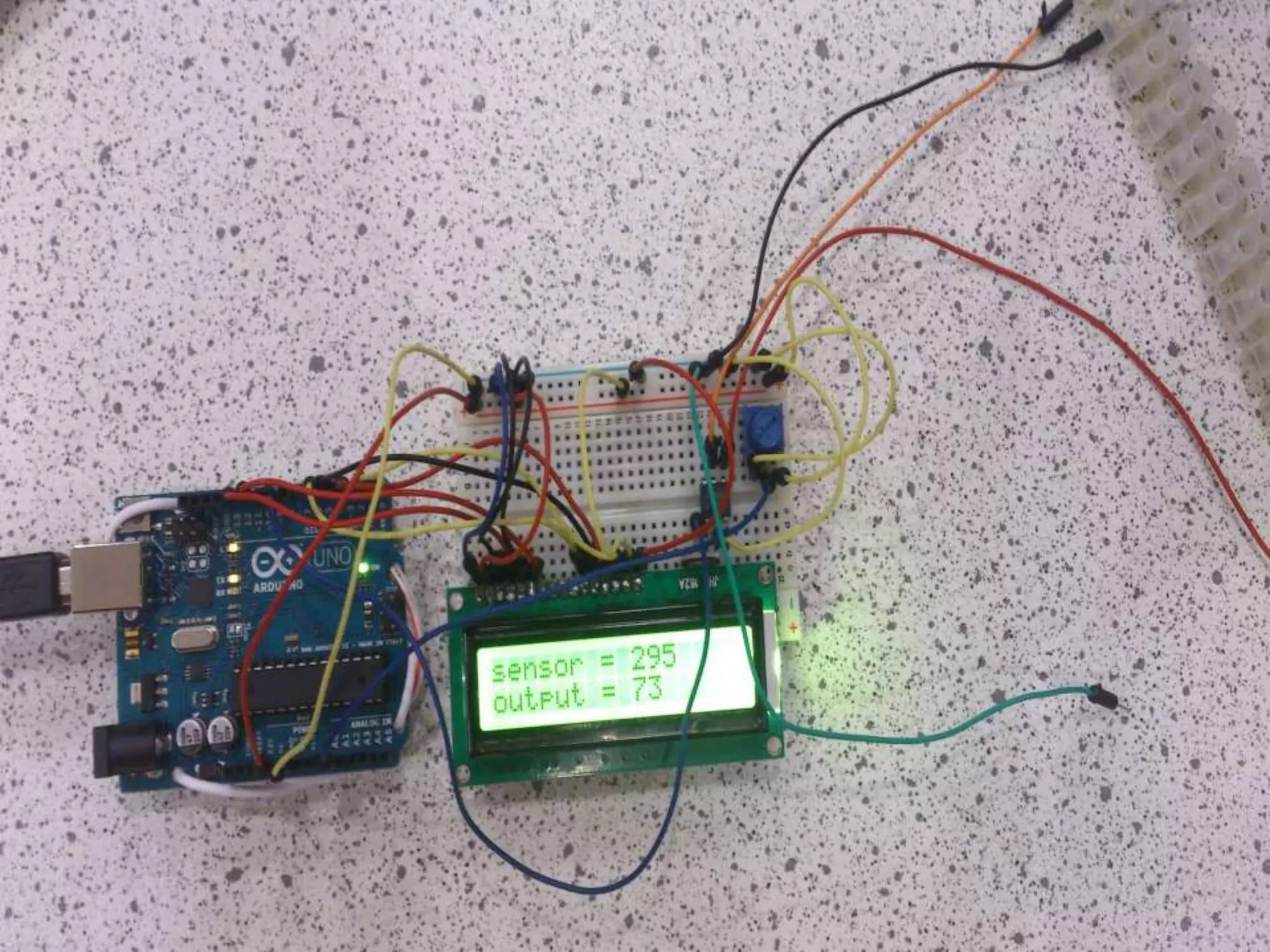

This document discusses the design of a hybrid micro thermoelectric and Stirling engine system for power generation. The system aims to optimize output power by combining two power sources - thermoelectric and Stirling engine modules. Experimental results are presented on optimizing individual module performance by increasing temperature difference, changing module position, and using aluminum to better transfer heat. The design incorporates a DC-DC buck-boost converter to further optimize total output power of the hybrid system.