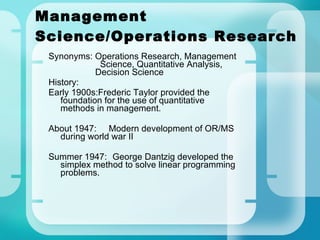

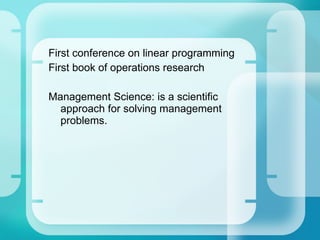

The document provides an overview of management science/operations research including:

- A brief history noting early developments and contributors.

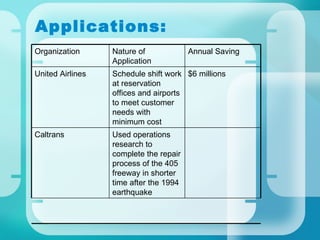

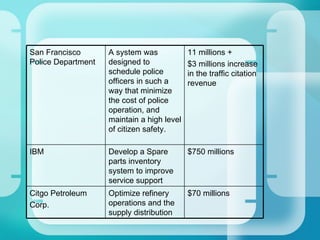

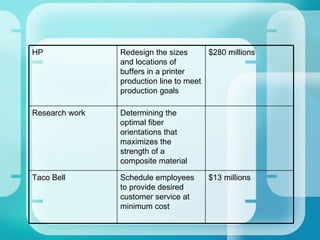

- Applications across various industries showing cost savings and increased revenues.

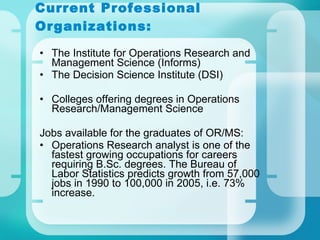

- Current professional organizations and typical jobs for graduates.

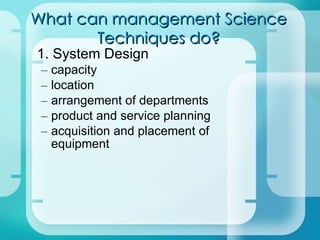

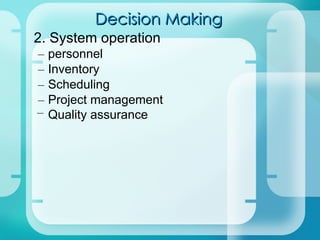

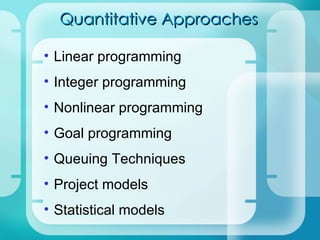

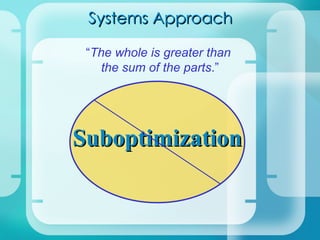

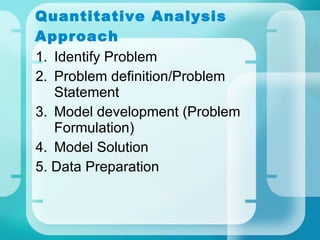

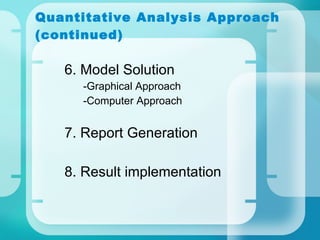

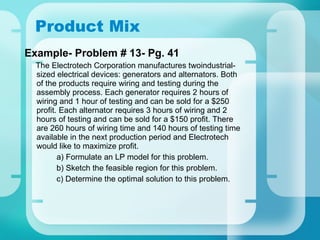

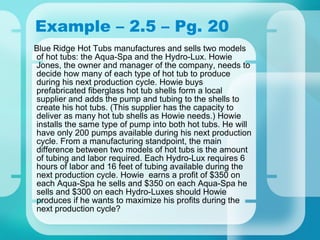

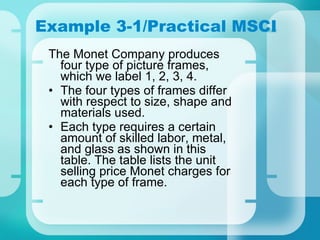

- How management science techniques can help with system design, operation, and decision making.

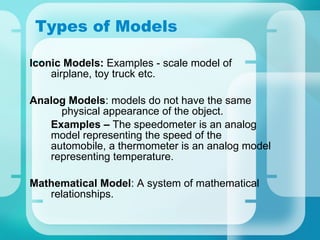

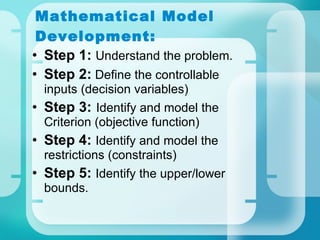

- The benefits and tradeoffs of different model types like iconic, analog, and mathematical models.