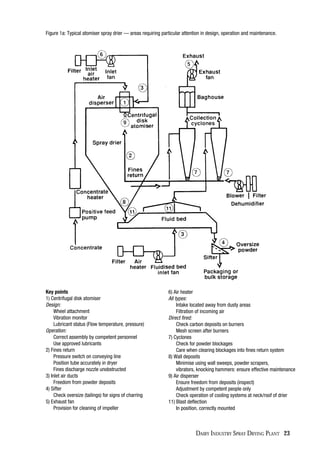

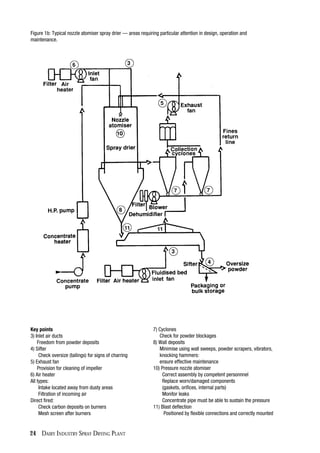

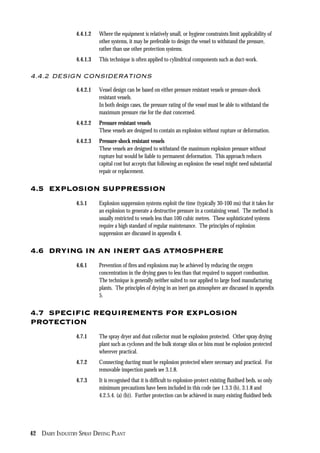

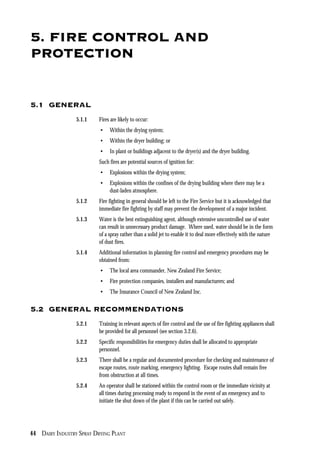

This document is an approved code of practice for preventing, detecting, and controlling fires and explosions in New Zealand dairy industry spray drying plants. It provides guidance for designers, manufacturers, and users of spray drying equipment on hazards and hazard prevention, recommendations and requirements for processing equipment and management responsibilities, explosion protection, and fire control and protection. The code applies to spray drying plants, fluidized bed dryers, dust collection equipment, bulk storage facilities, and related powder handling equipment. It sets timelines for existing equipment to comply with the code and provides some exemptions.