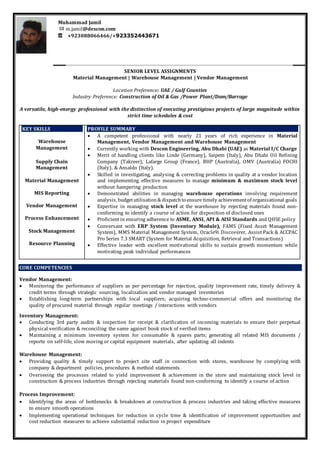

Muhammad Jamil has over 21 years of experience in material management, warehouse management, and vendor management. He currently works as the Material-in-Charge for Descon Engineering in Abu Dhabi, UAE. He has extensive experience managing warehouses and inventory for large construction projects in oil, gas, and power industries. He is skilled in vendor evaluation, inventory control, warehouse operations, and process improvement.