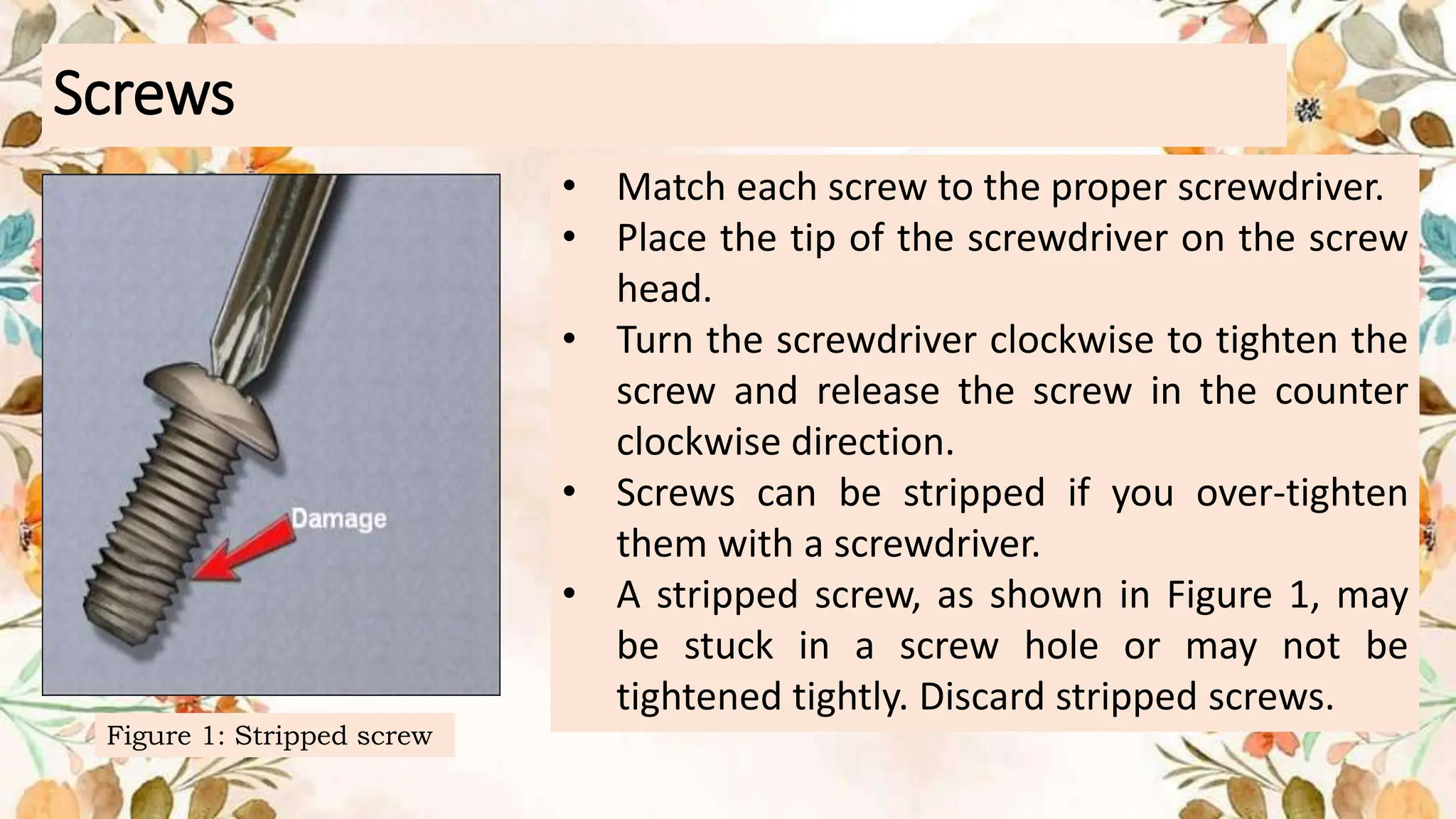

The document discusses the proper use and identification of various common hand tools used in computer assembly and repair, including screwdrivers, pliers, wire cutters, and tweezers. It emphasizes the importance of using the correct tool for each task and following safety procedures to prevent damage to equipment and injury. A variety of hand tools are demonstrated along with best practices for their safe and effective use in computer maintenance and troubleshooting activities.