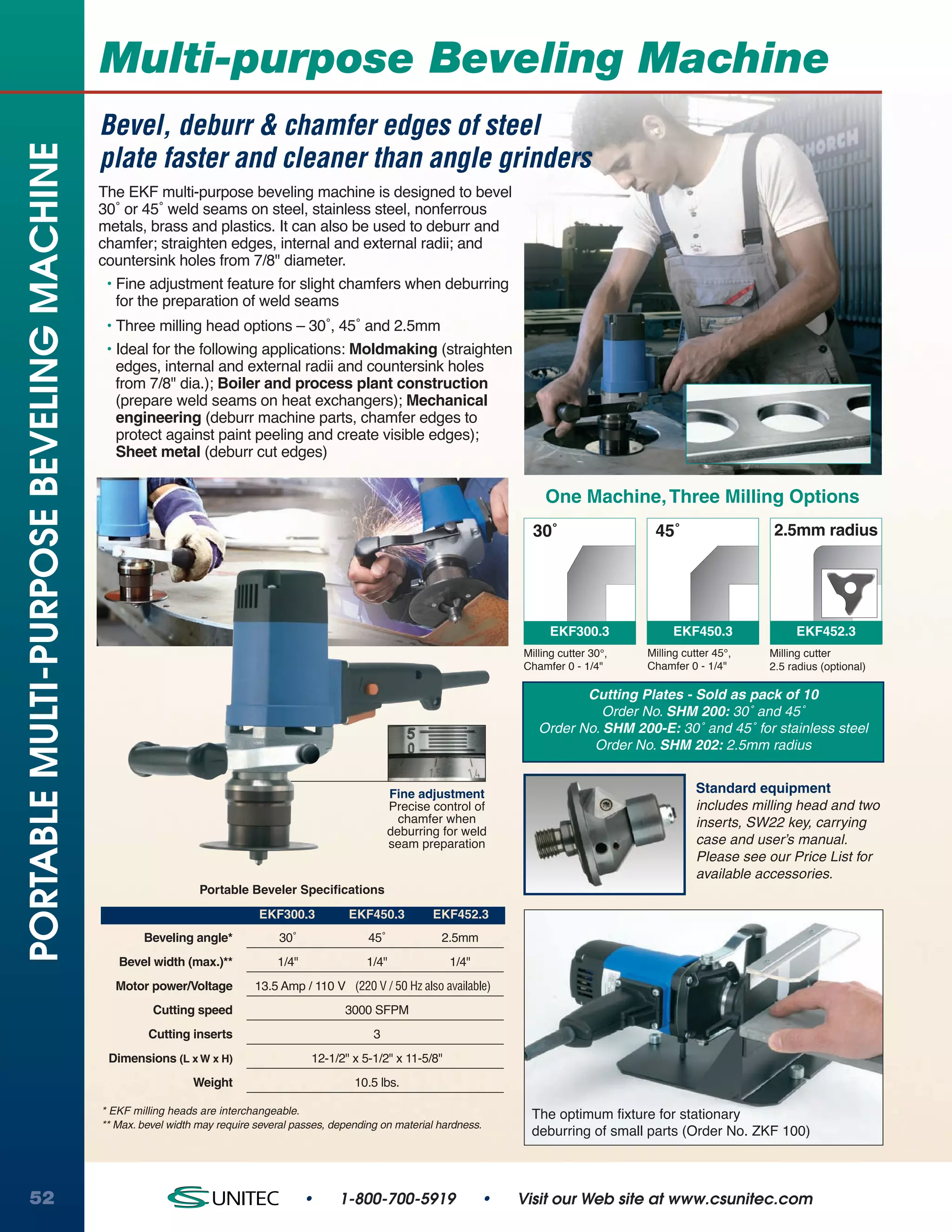

The EKF multi-purpose beveling machine efficiently bevels, deburrs, and chamfers edges of various materials including steel and plastics at angles of 30° and 45°. It is equipped with three milling head options and a fine adjustment feature for precise control, making it ideal for applications in moldmaking, boiler construction, and mechanical engineering. The machine is portable, with specifications including a motor power of 13.5 amps and cutting speed of 3000 sfpm.