1) The document provides instructions for completing various machining exercises using different machines like the lathe, milling machine, drilling machine, shaping machine, and capstan lathe.

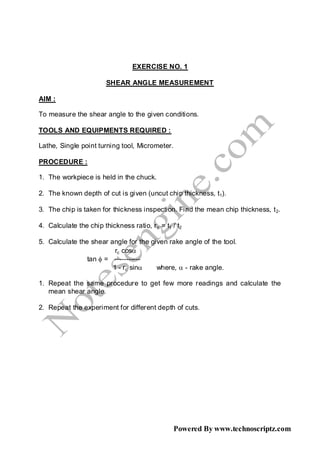

2) The exercises include measuring shear angle, machining internal keyways, surface grinding, assembling bolts and nuts, assembling dies and punches, assembling flange couplings, and machining spur gears and hexagons.

3) Detailed procedures are provided for setting up and operating the machines to machine workpieces to the required dimensions, including calculating necessary values, marking dimensions, fixing and securing workpieces, and checking final results.