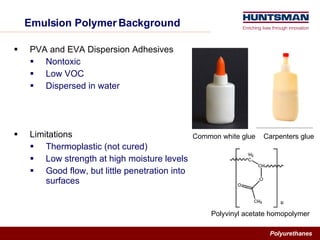

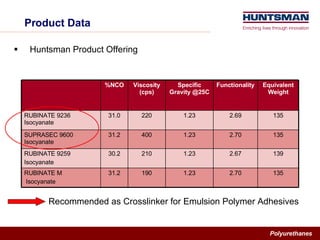

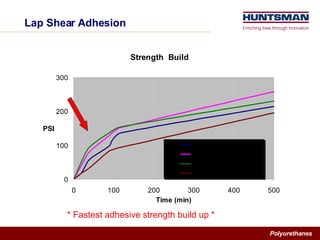

This document discusses crosslinking technology for latex or acrylic emulsions using isocyanate crosslinkers. It describes emulsion polymer isocyanate (EPI) adhesives which consist of an emulsion polymer like polyvinyl acetate or styrene-butadiene latex, and a crosslinking isocyanate like polymeric MDI or emulsifiable polymeric MDI. Adding an isocyanate crosslinker to an emulsion polymer increases adhesive strength, overall physical properties, and suitability for wet applications. Emulsifiable MDIs provide benefits like better mixing and reactivity control compared to traditional MDIs. The document recommends Huntsman's Rubinate 9236 and Suprasec 9600 products for EPI adhesive applications.