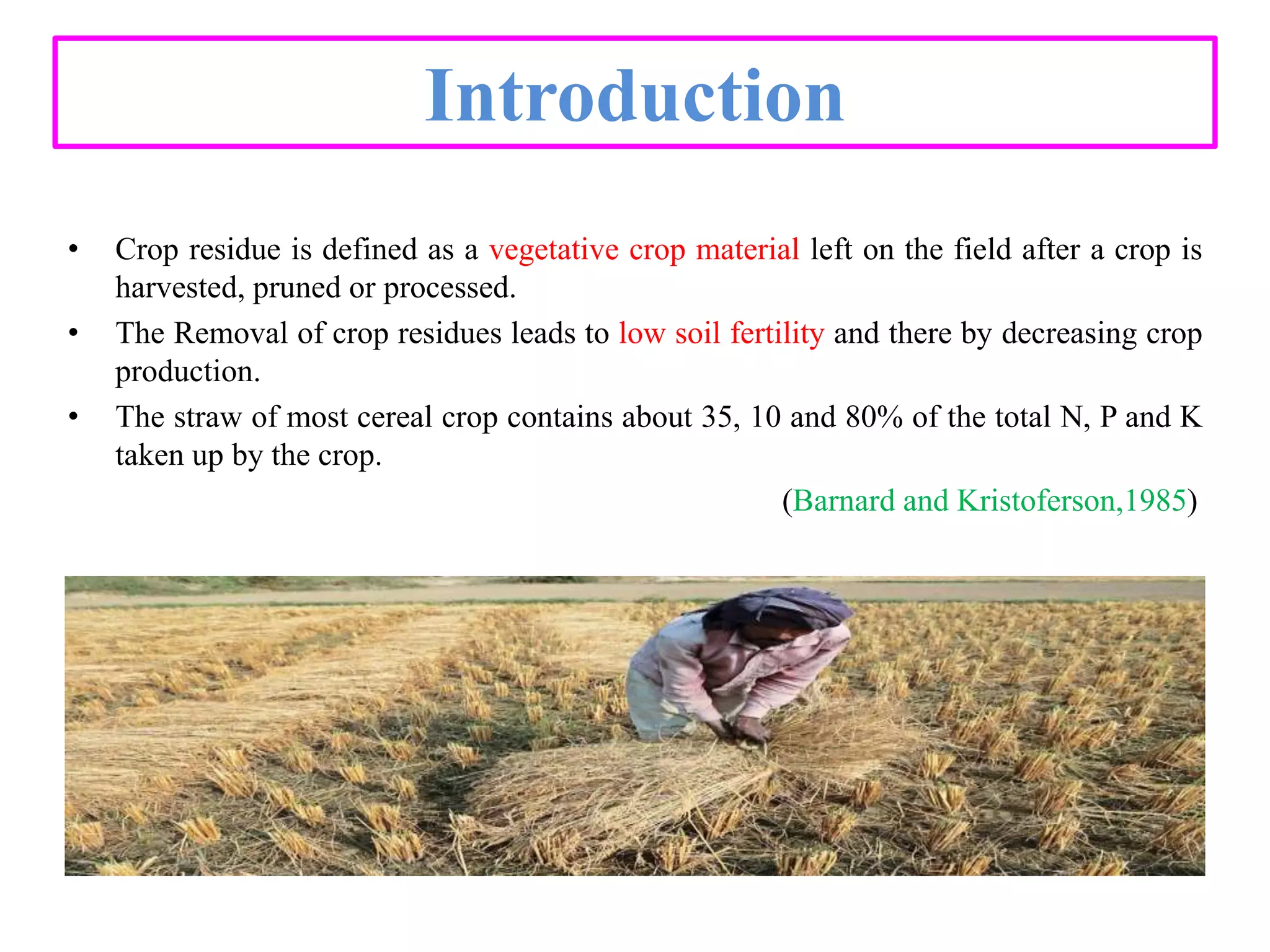

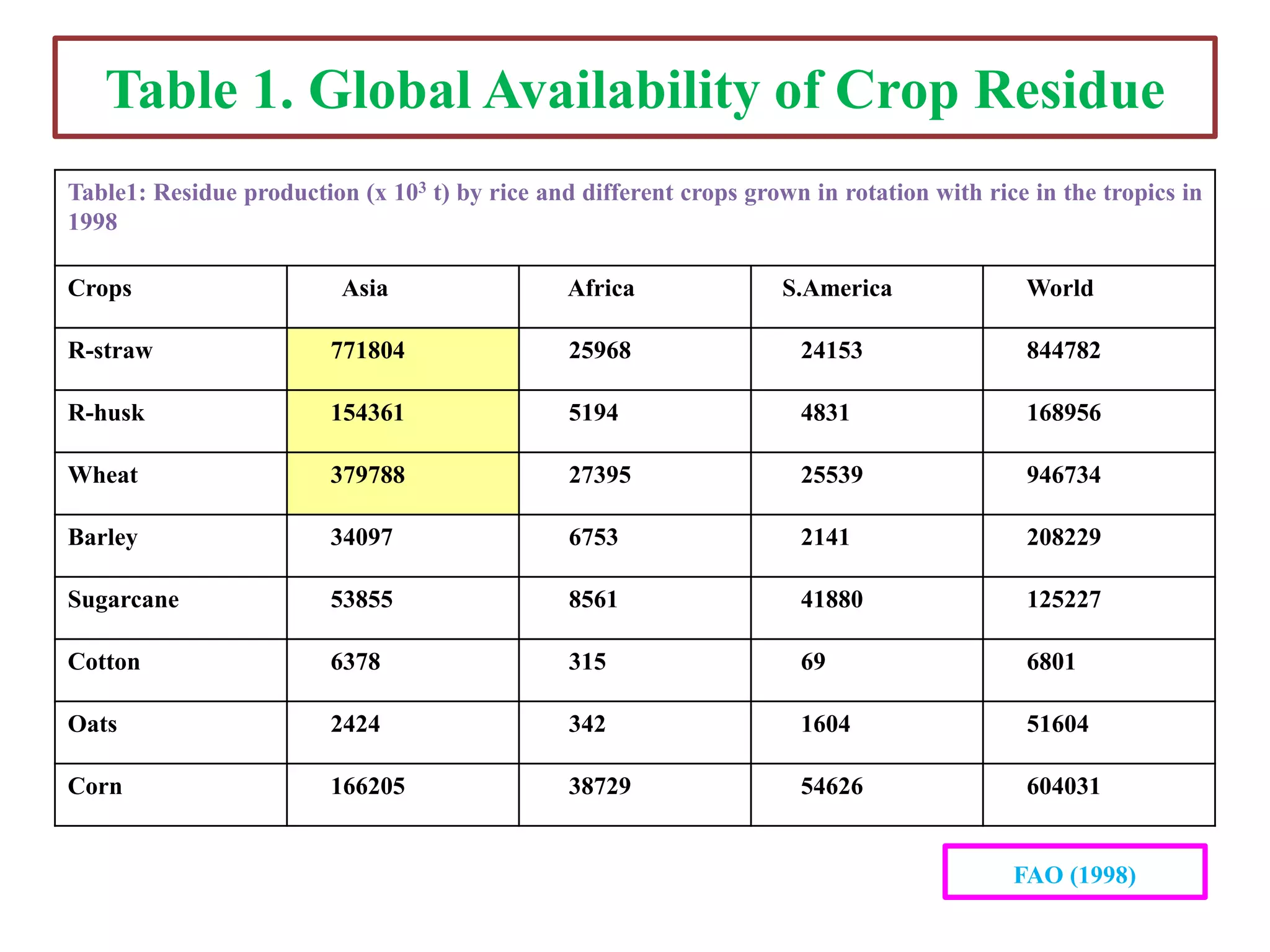

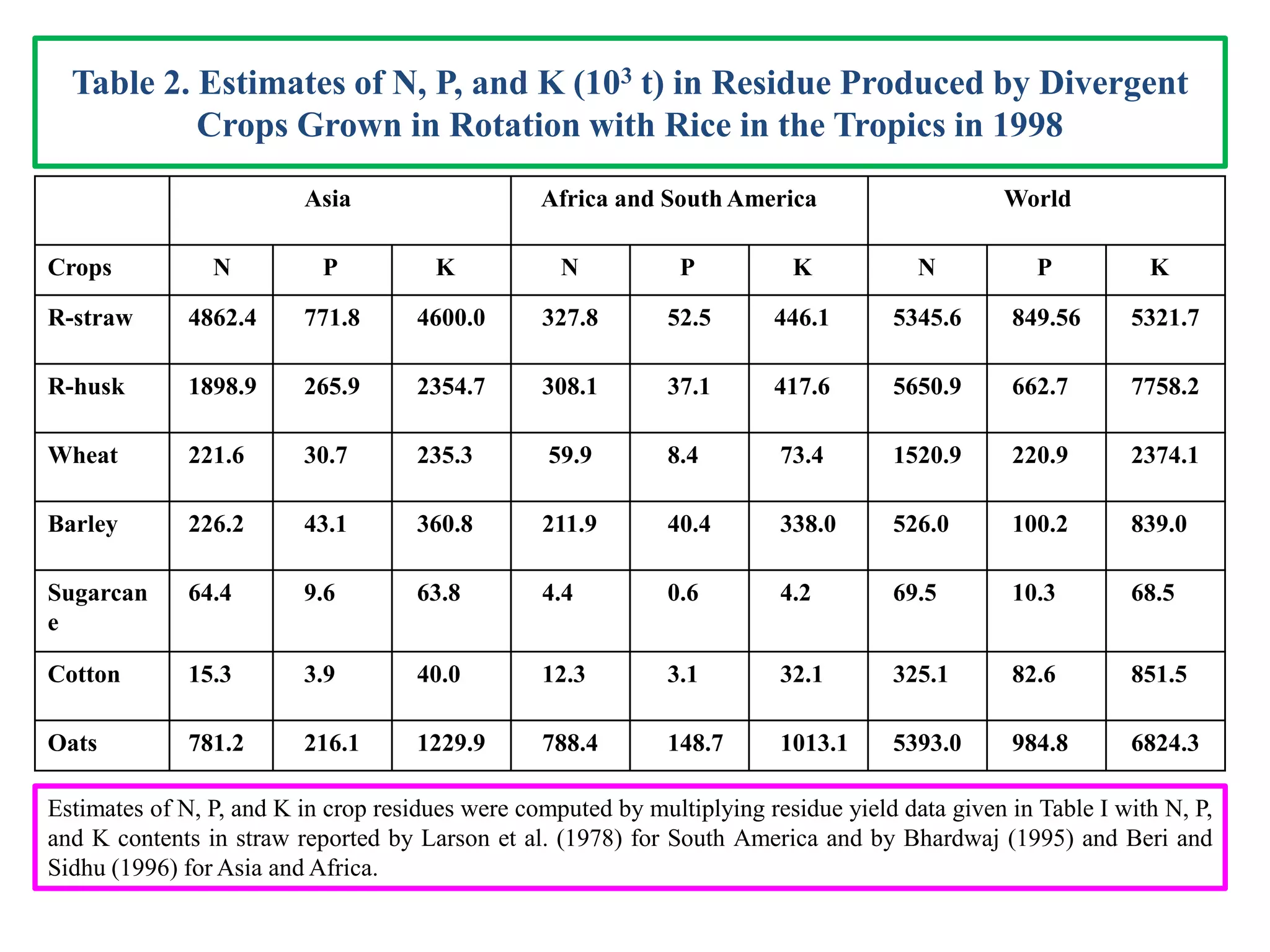

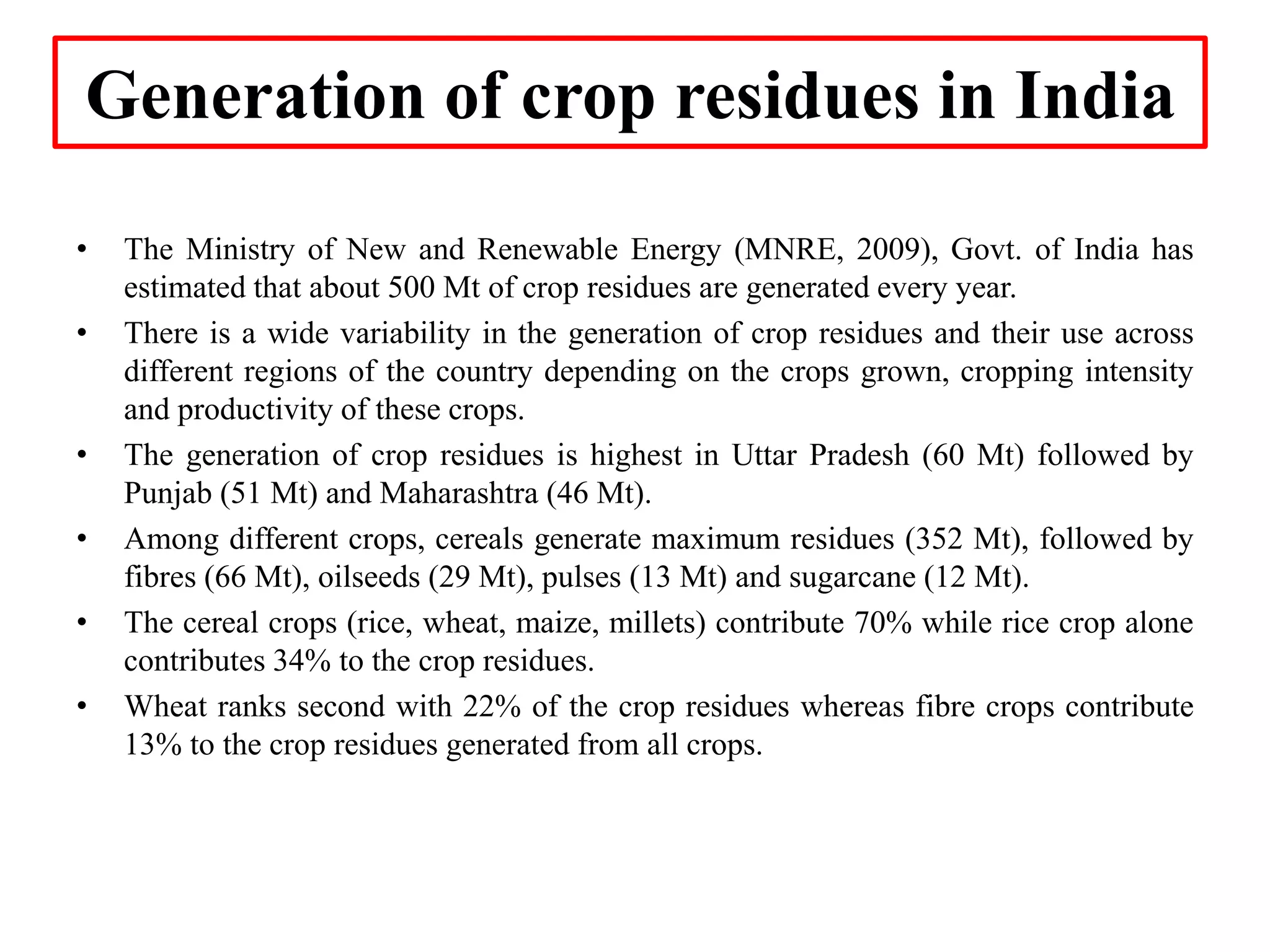

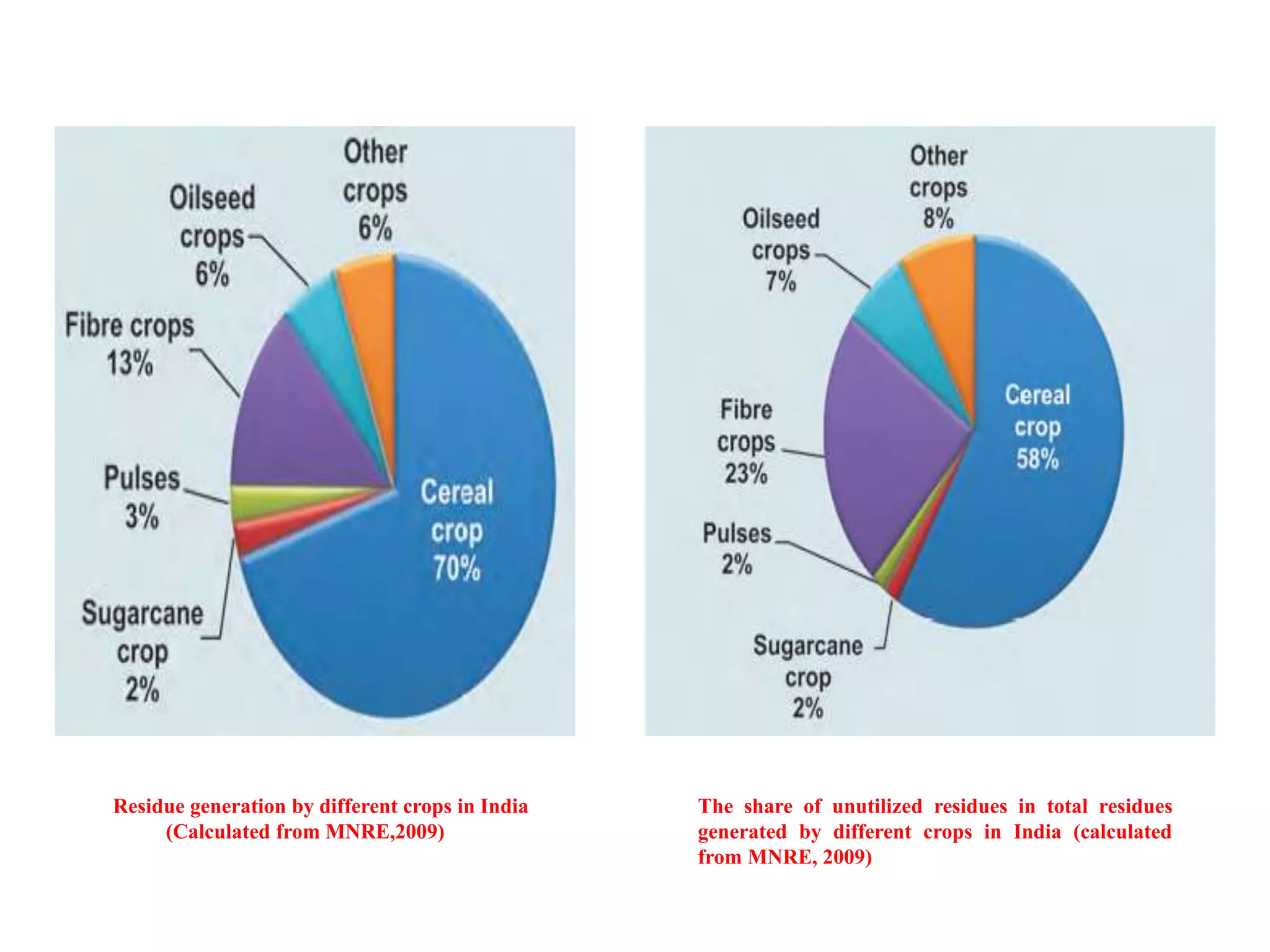

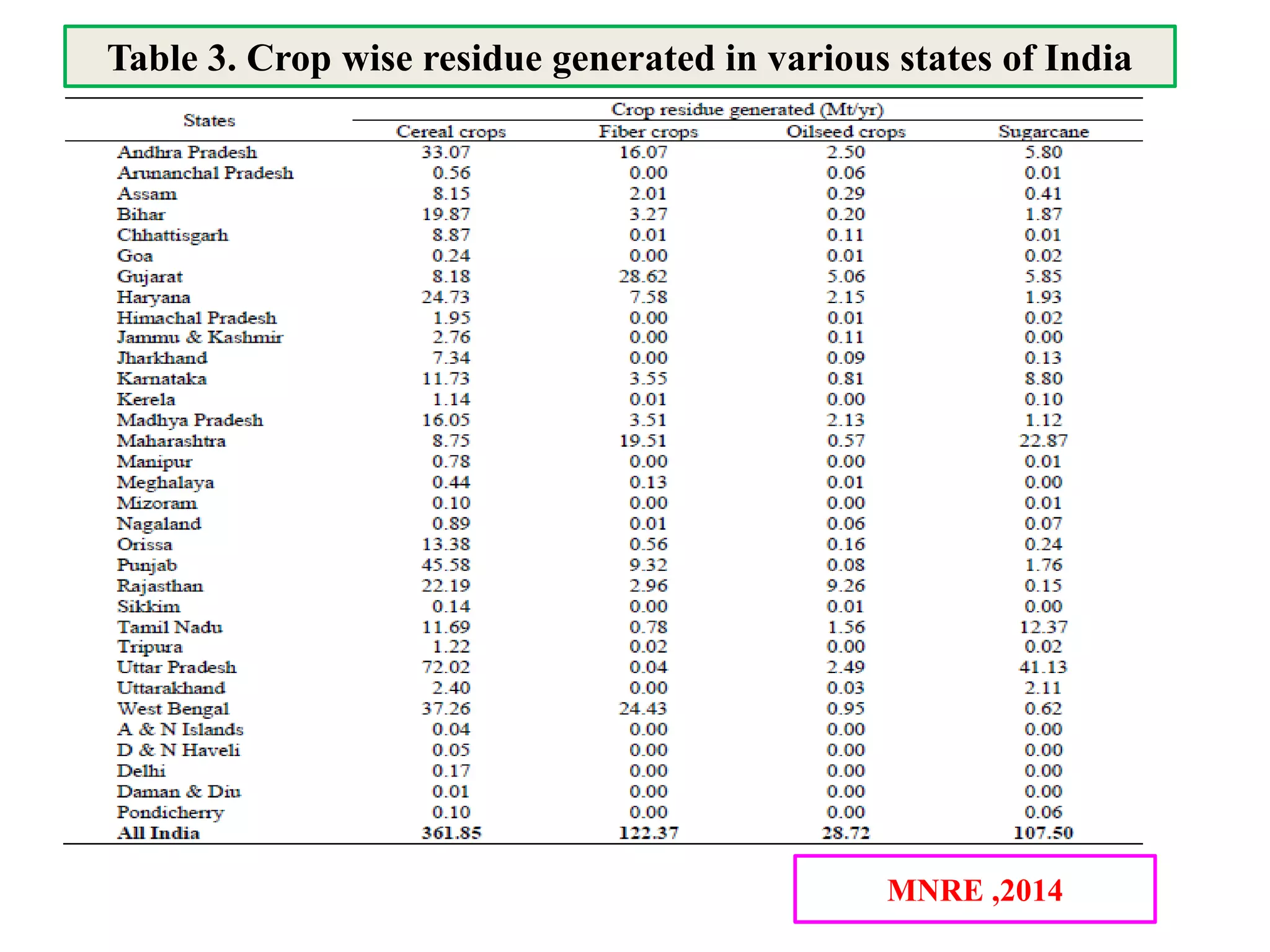

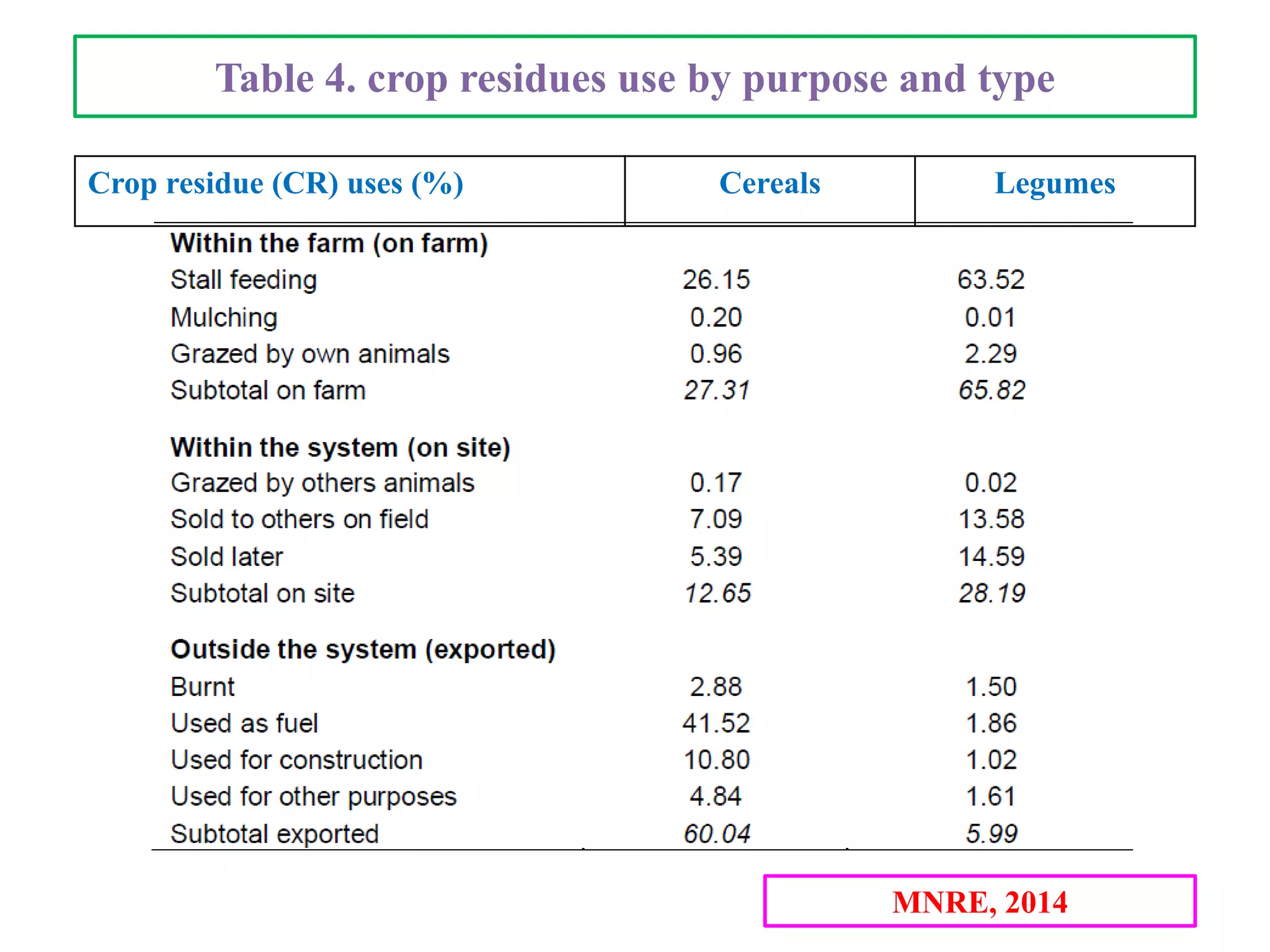

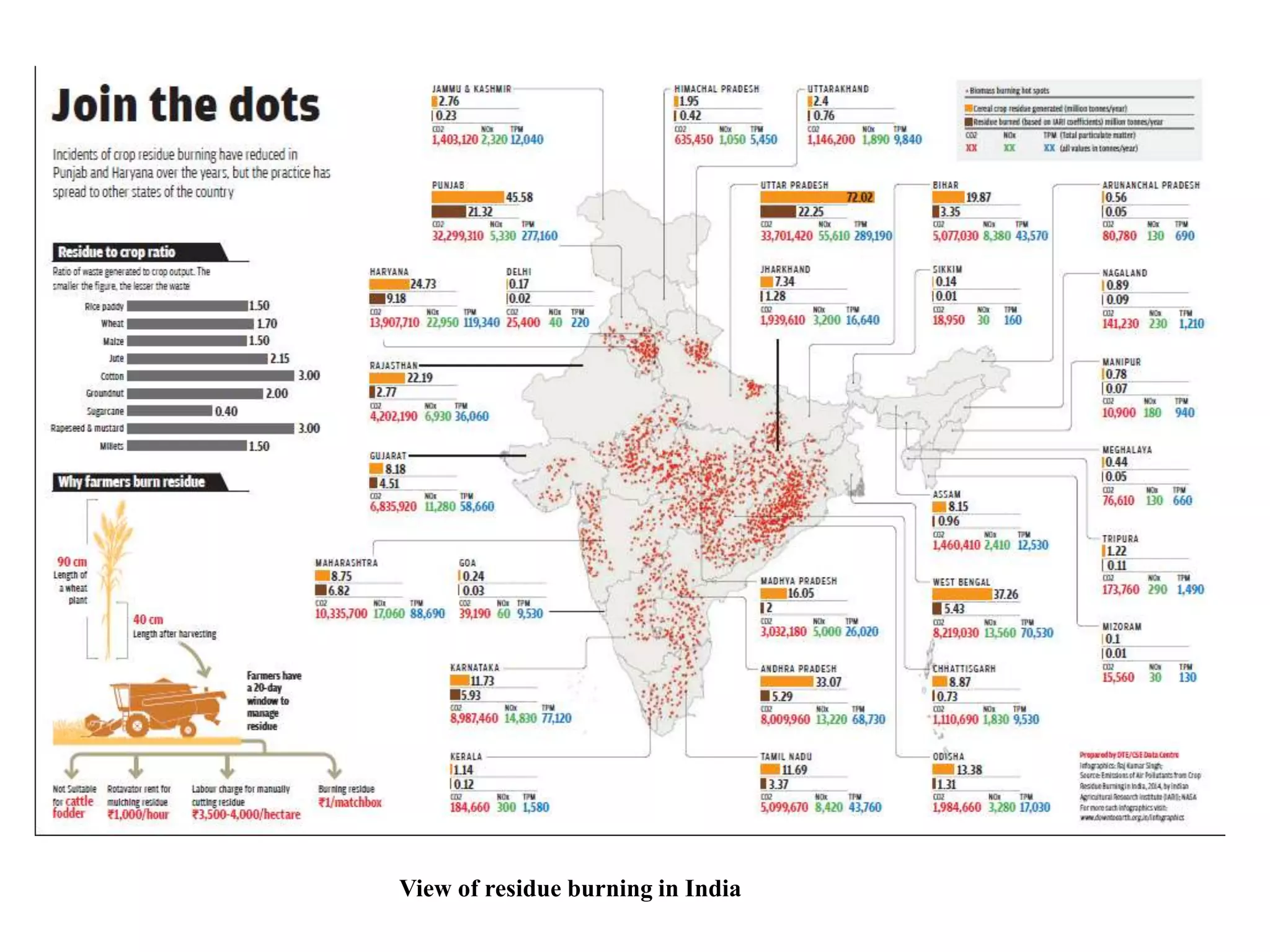

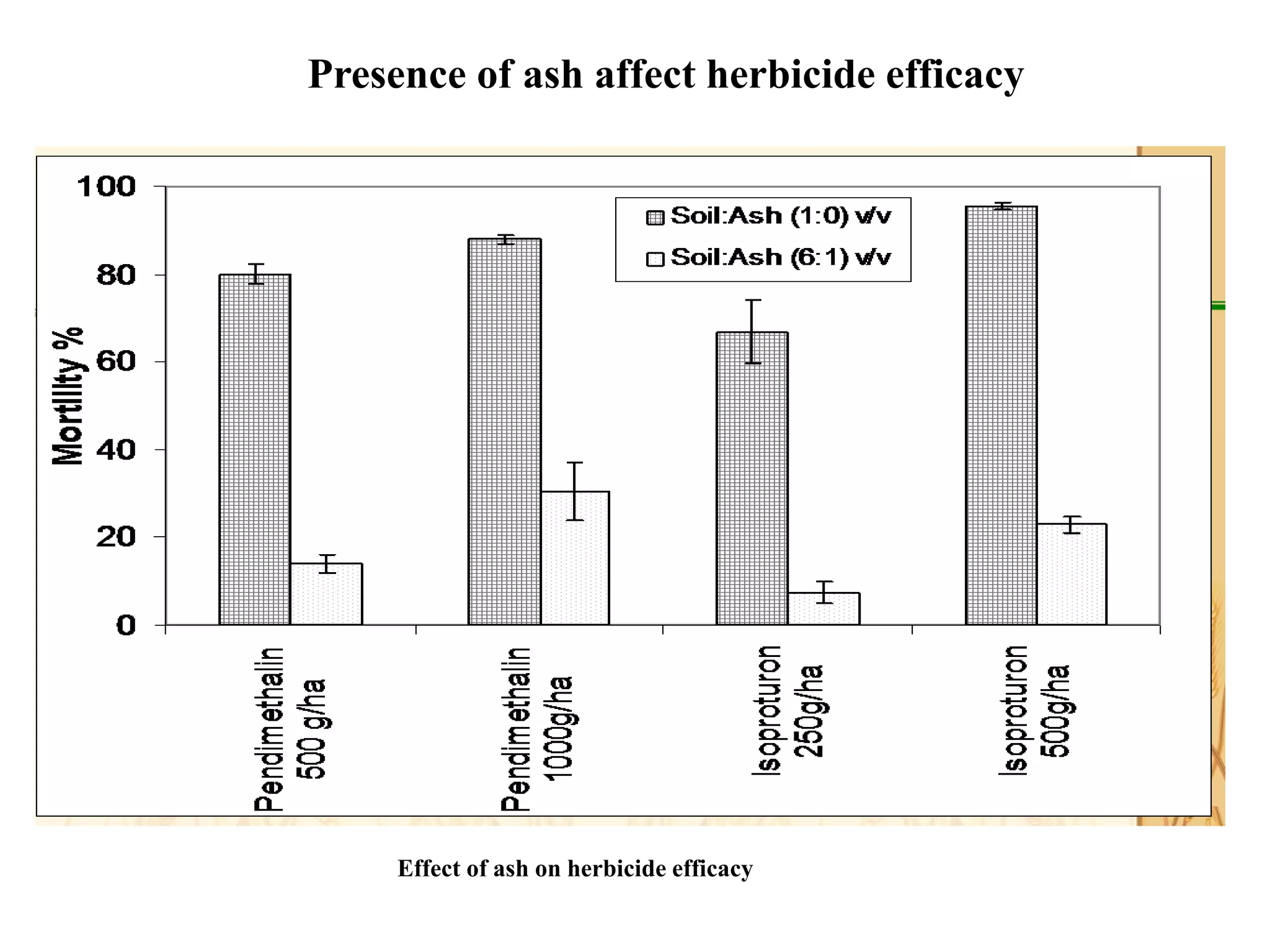

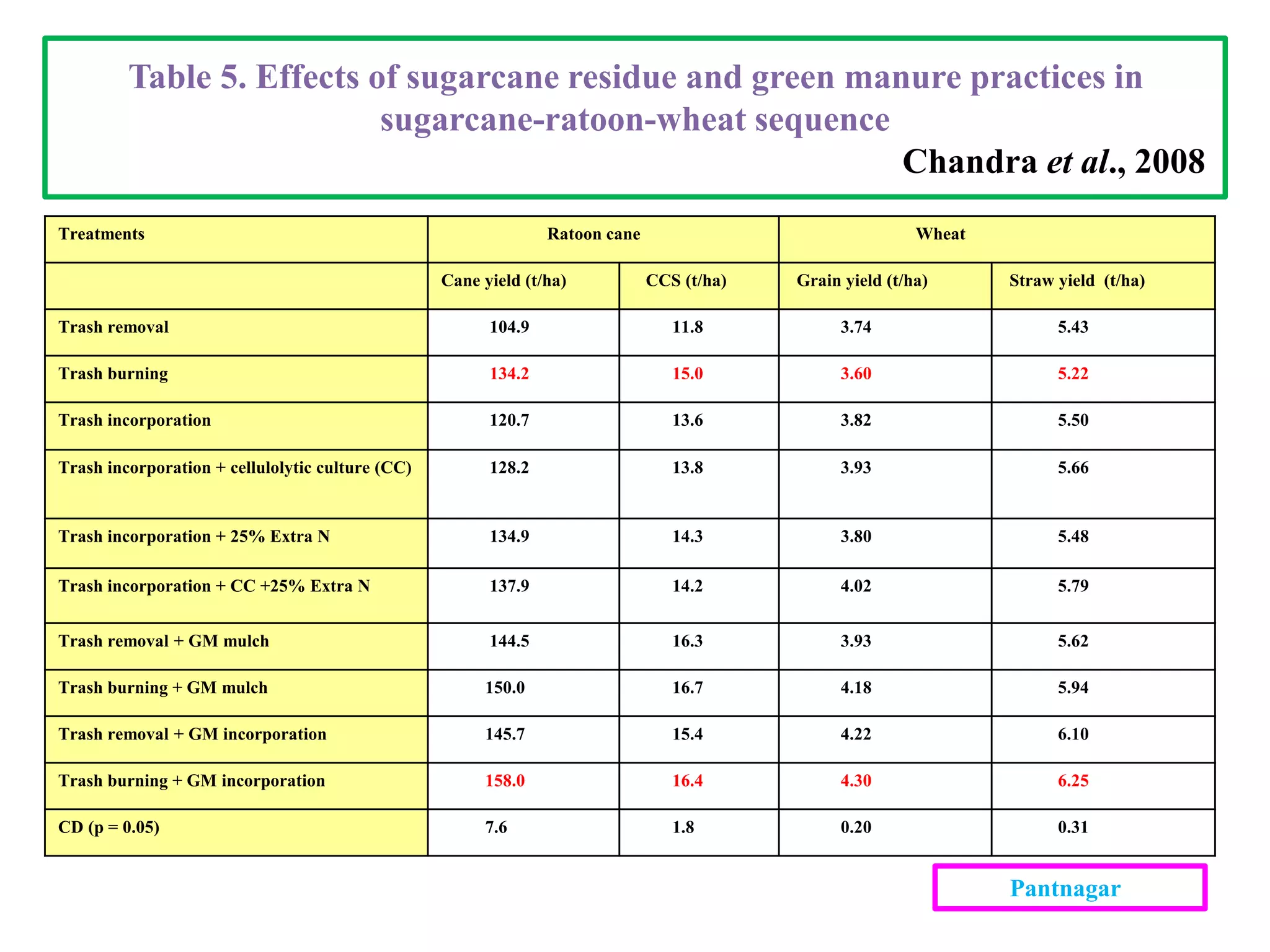

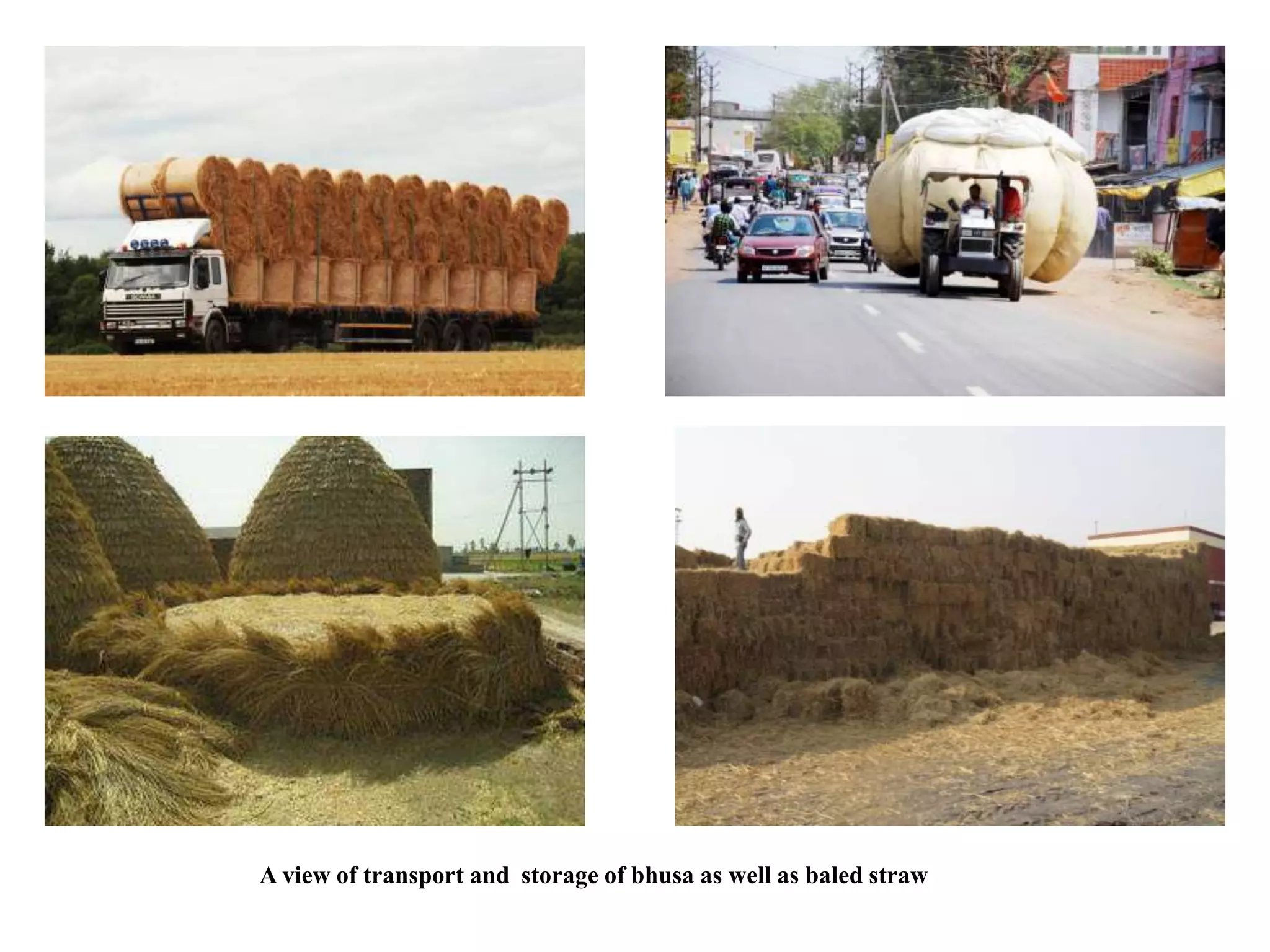

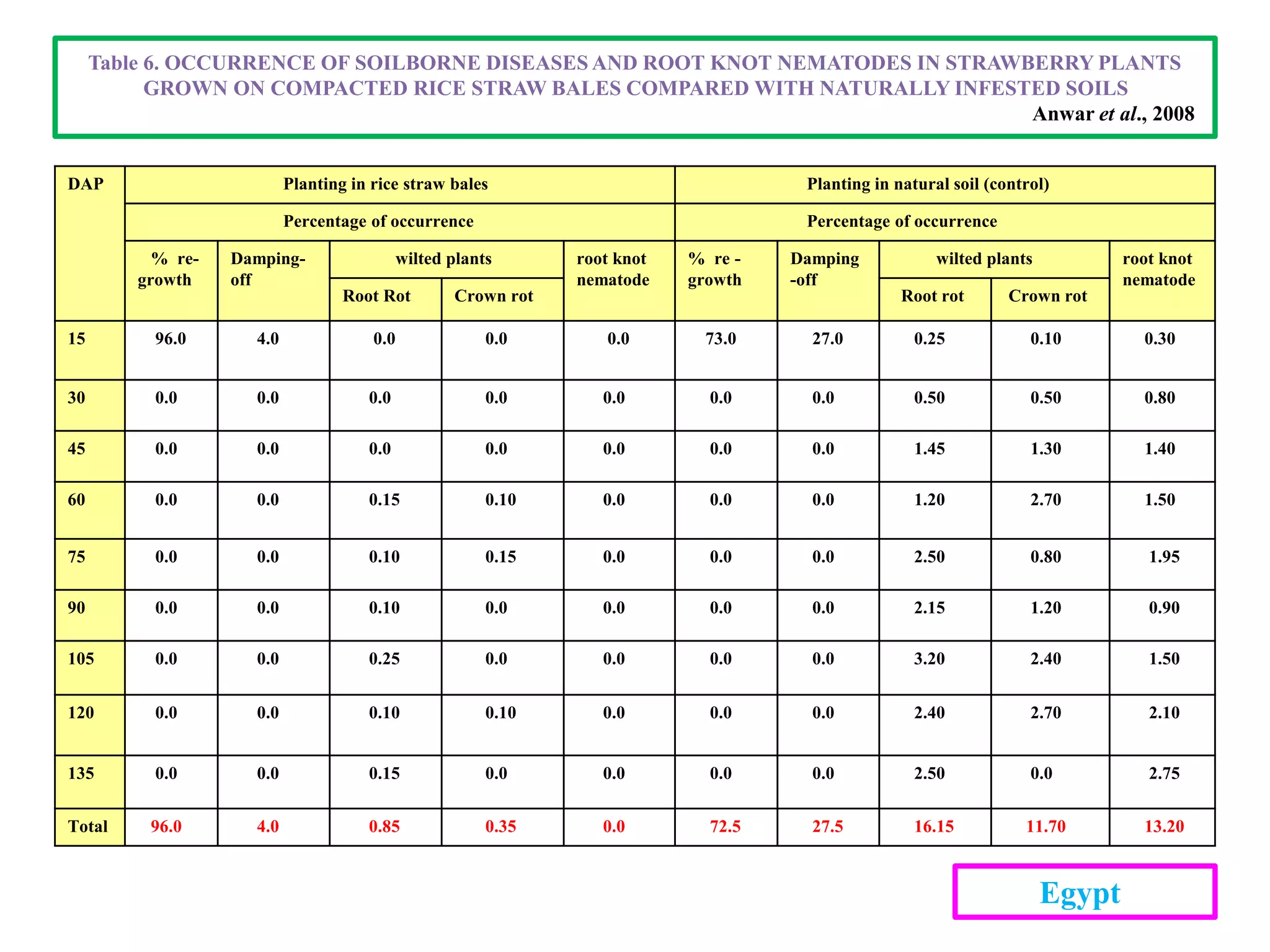

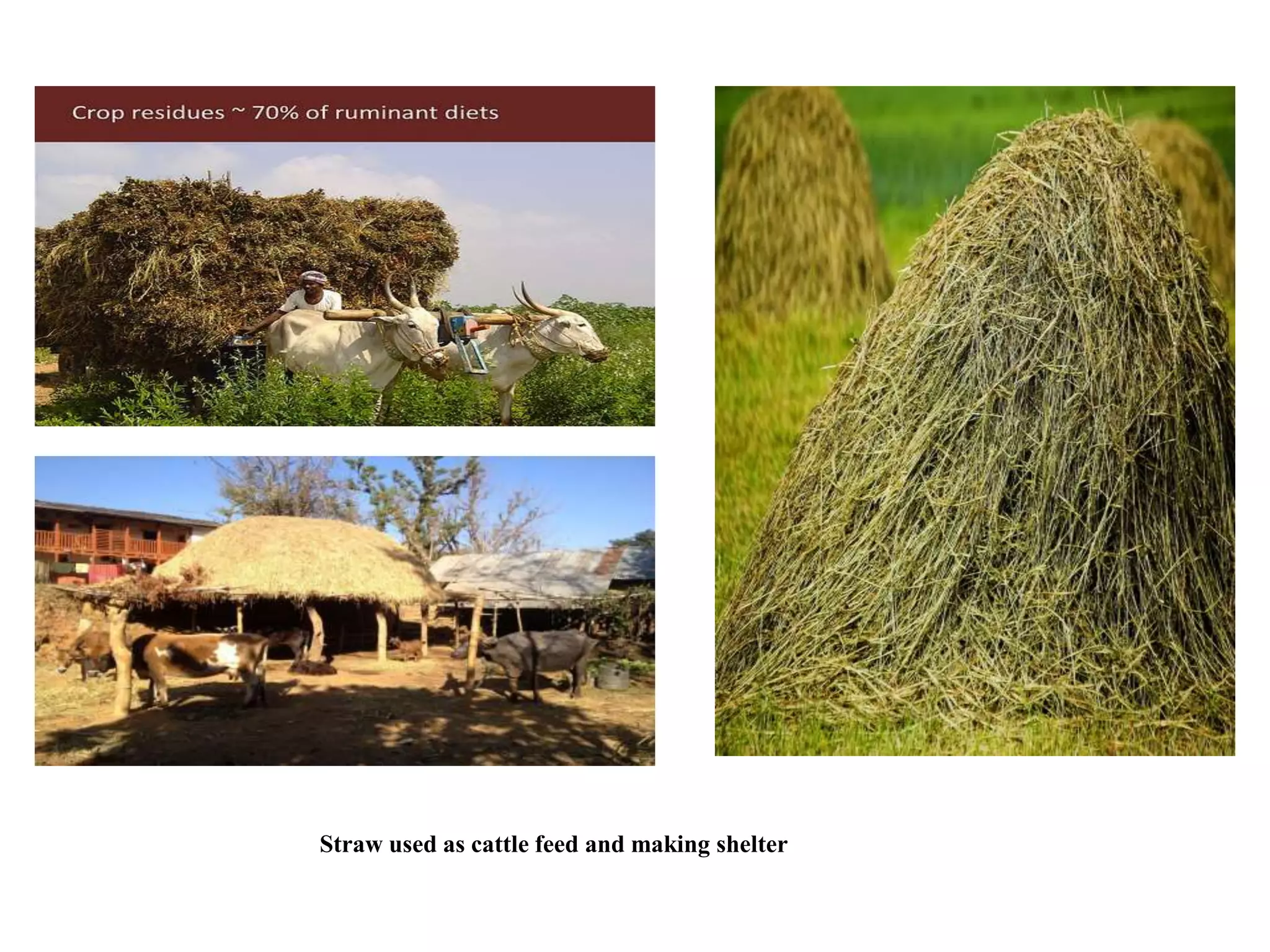

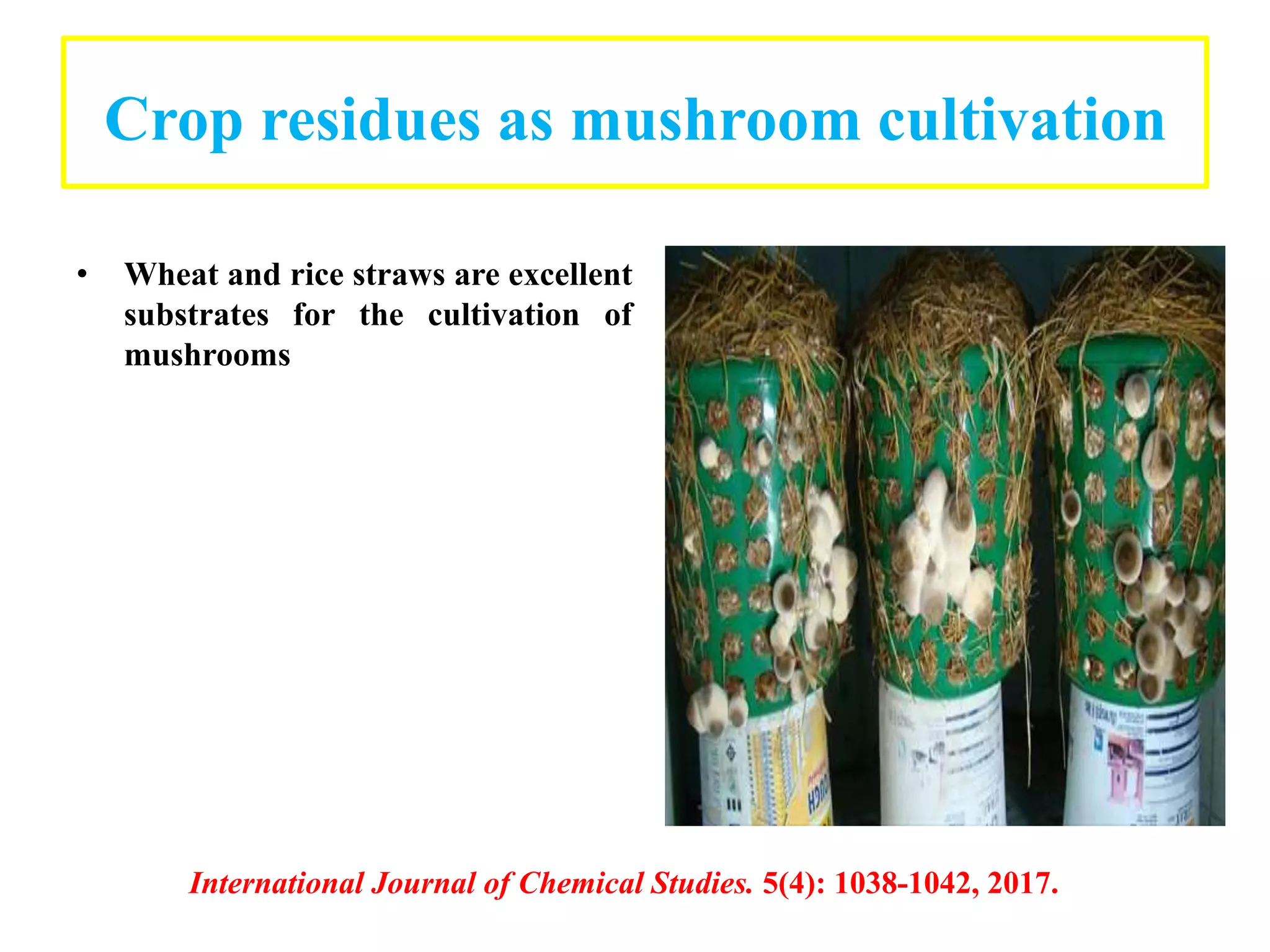

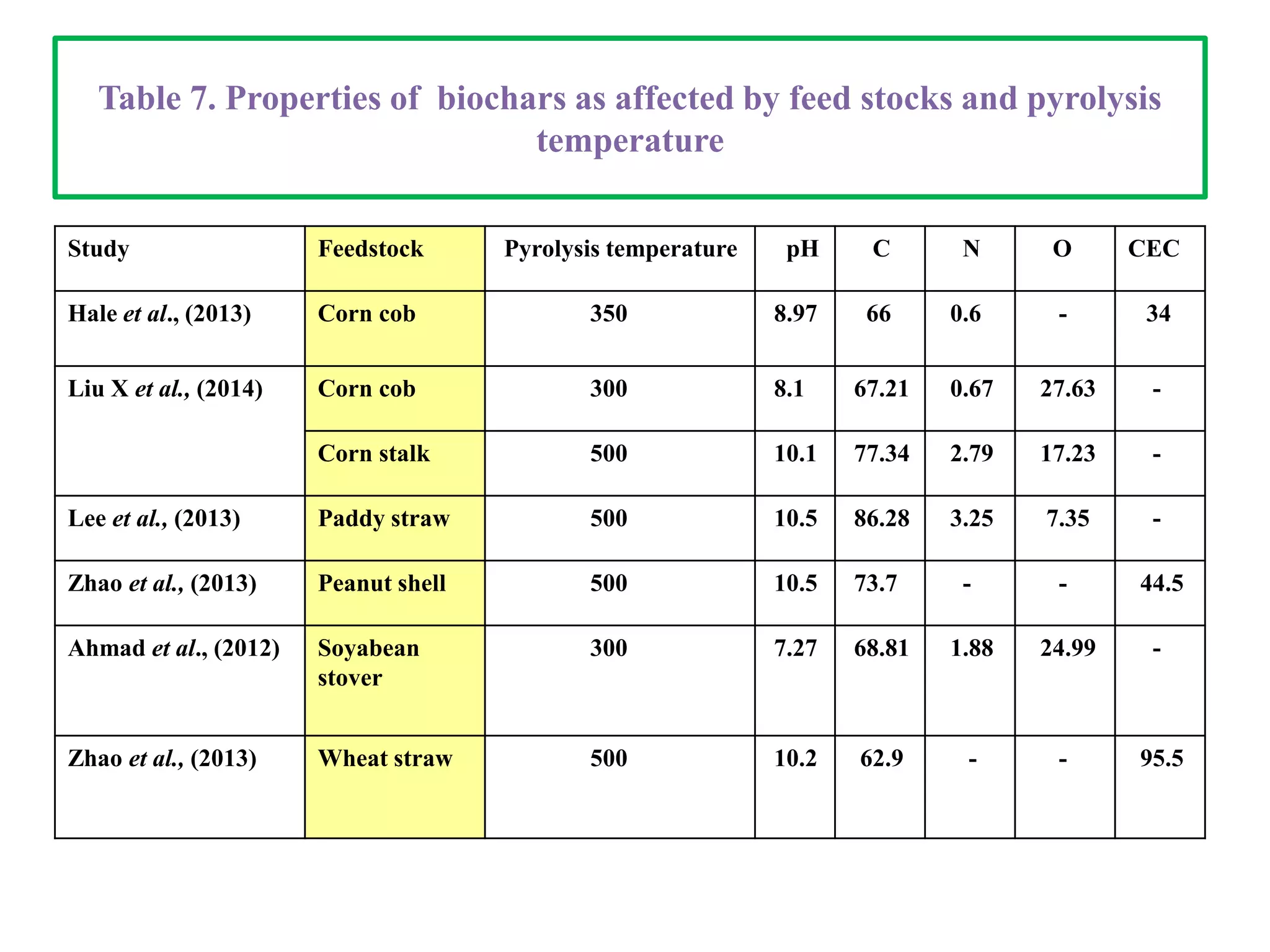

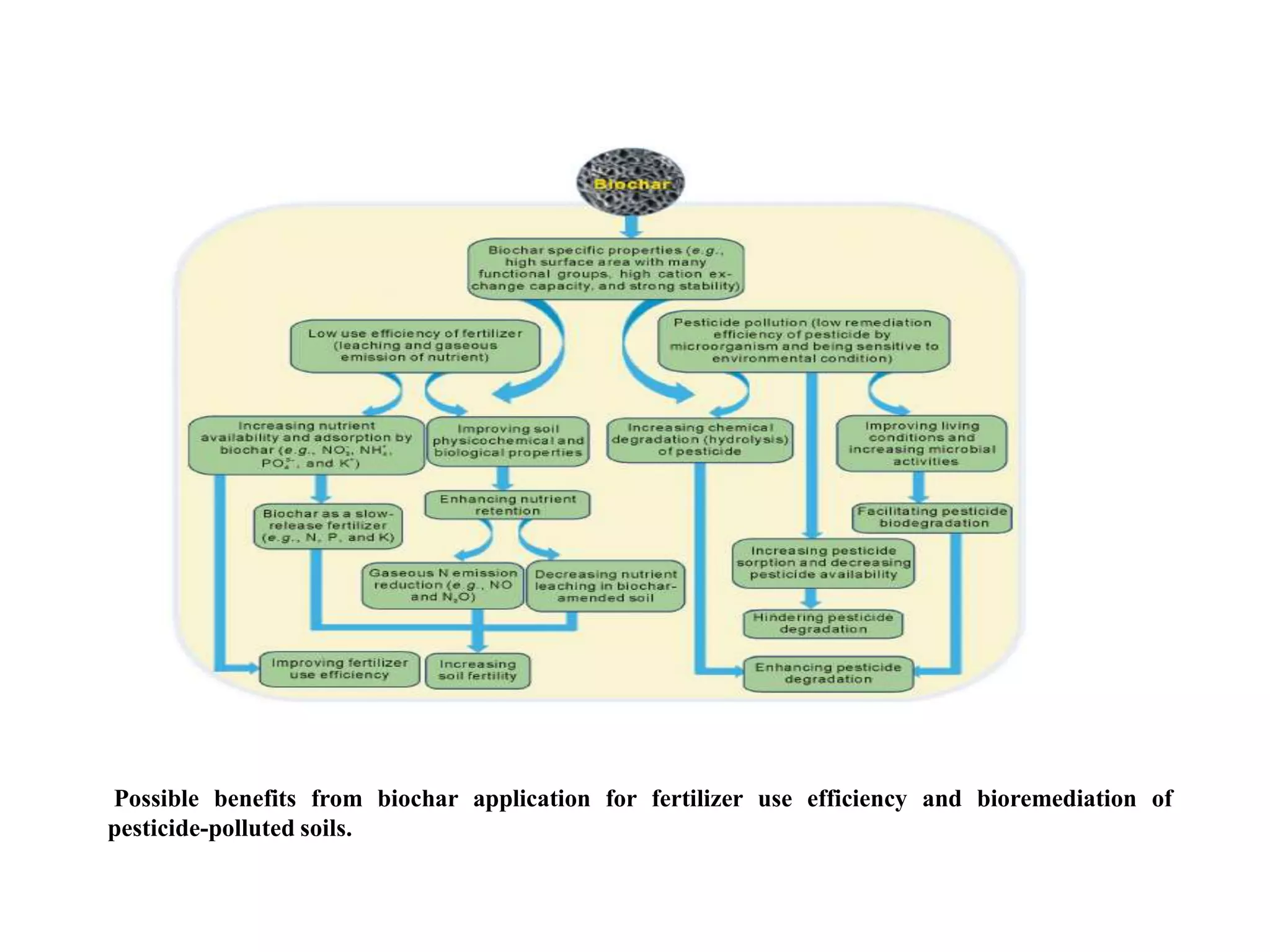

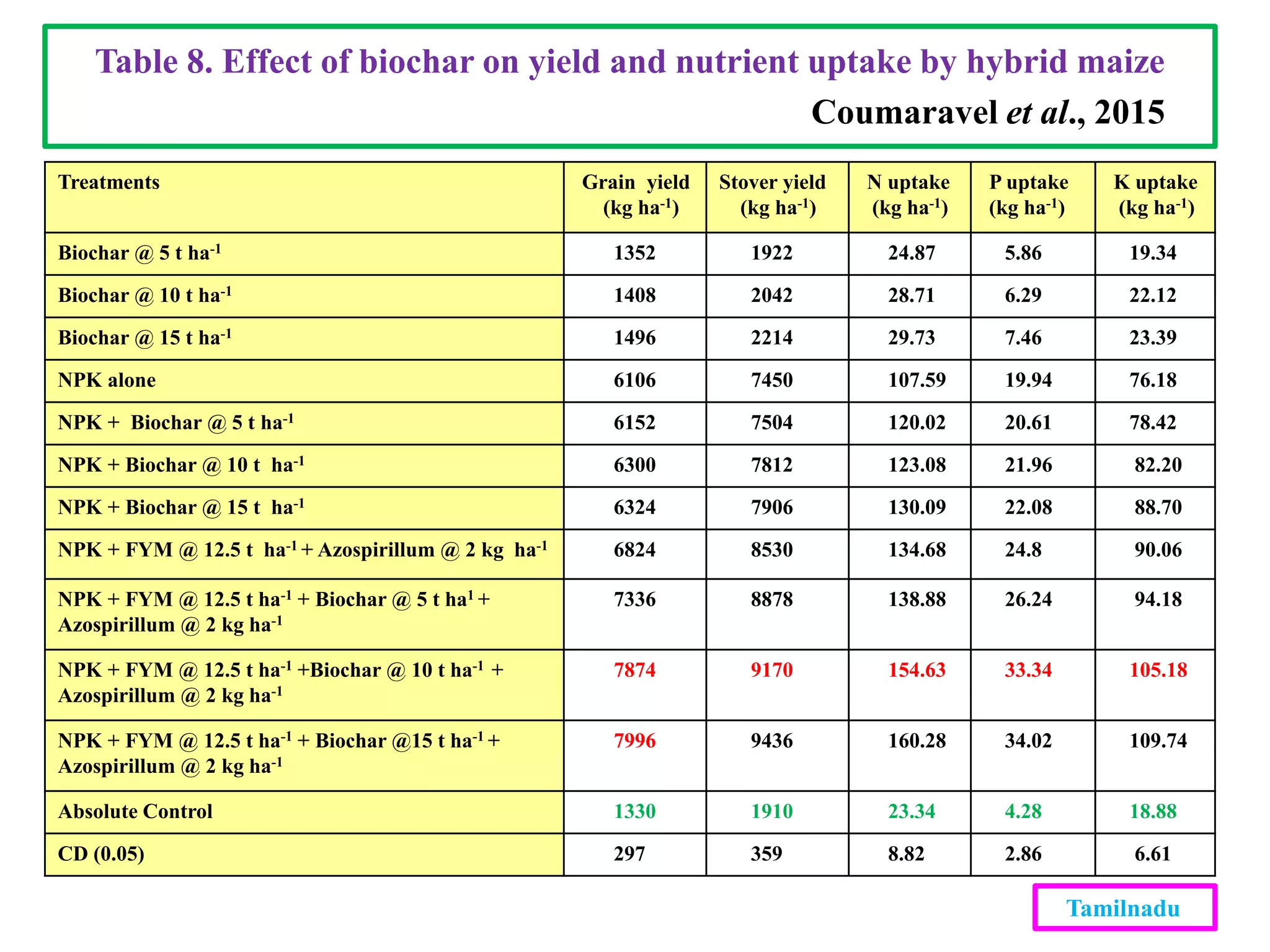

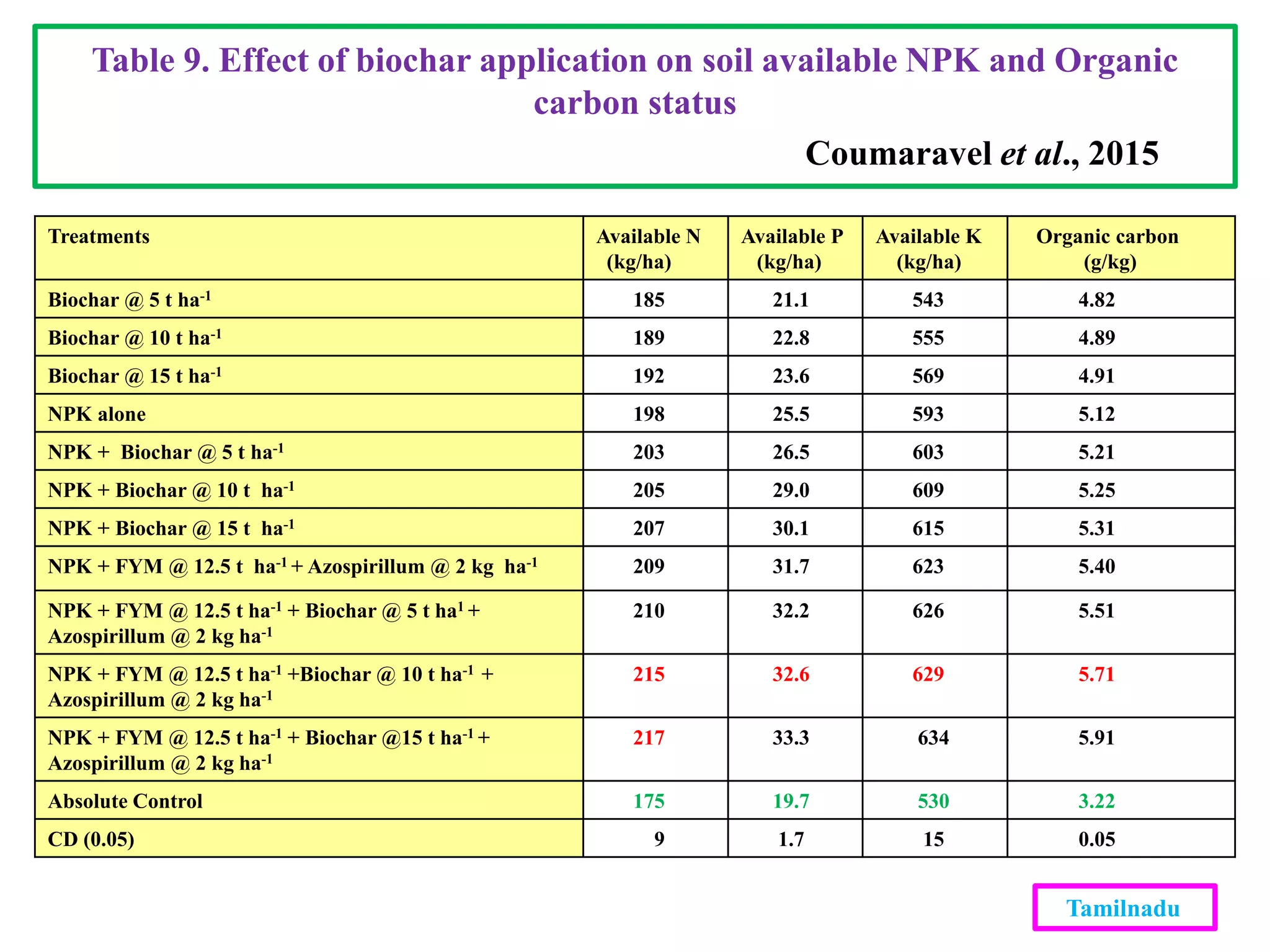

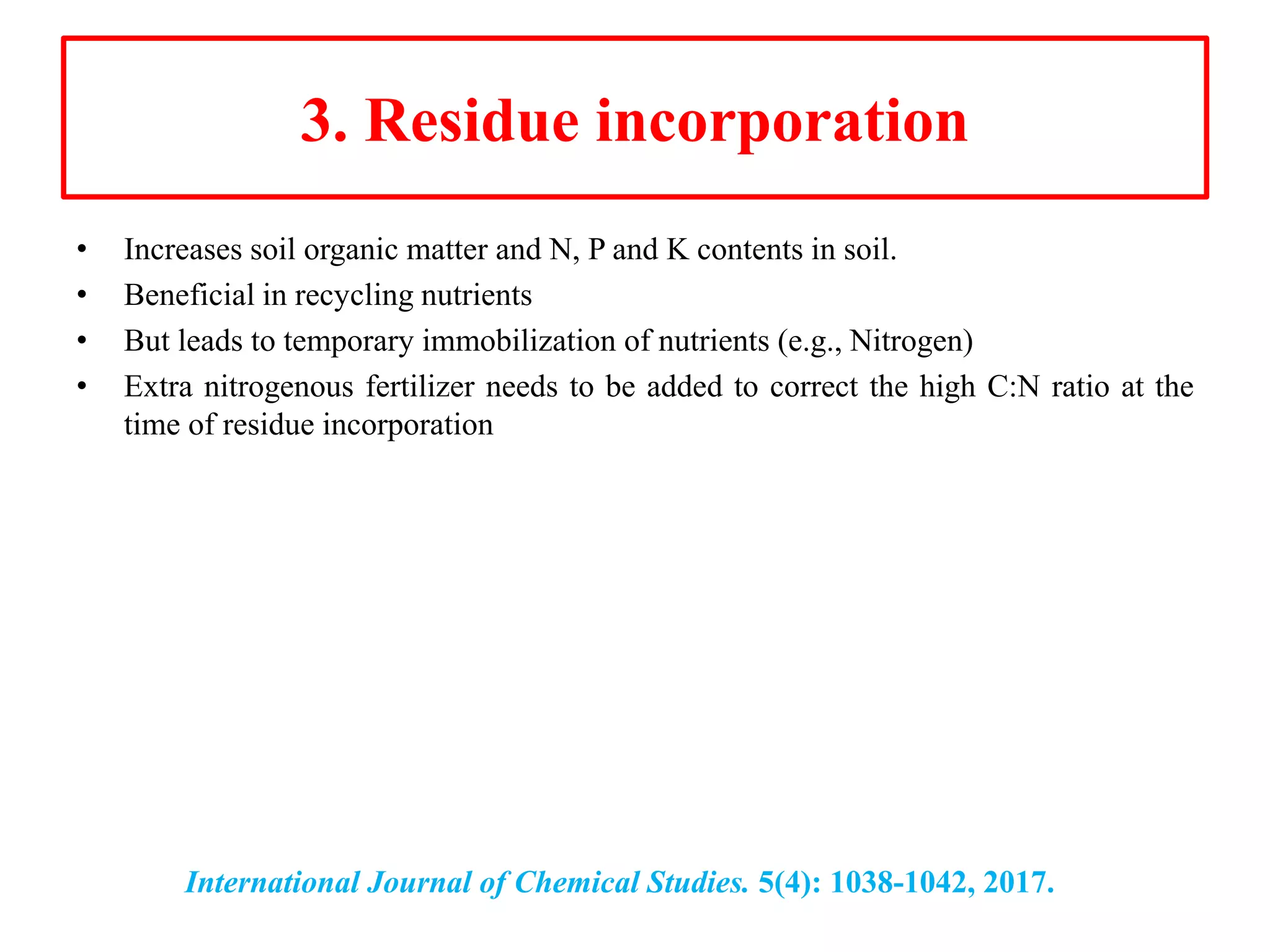

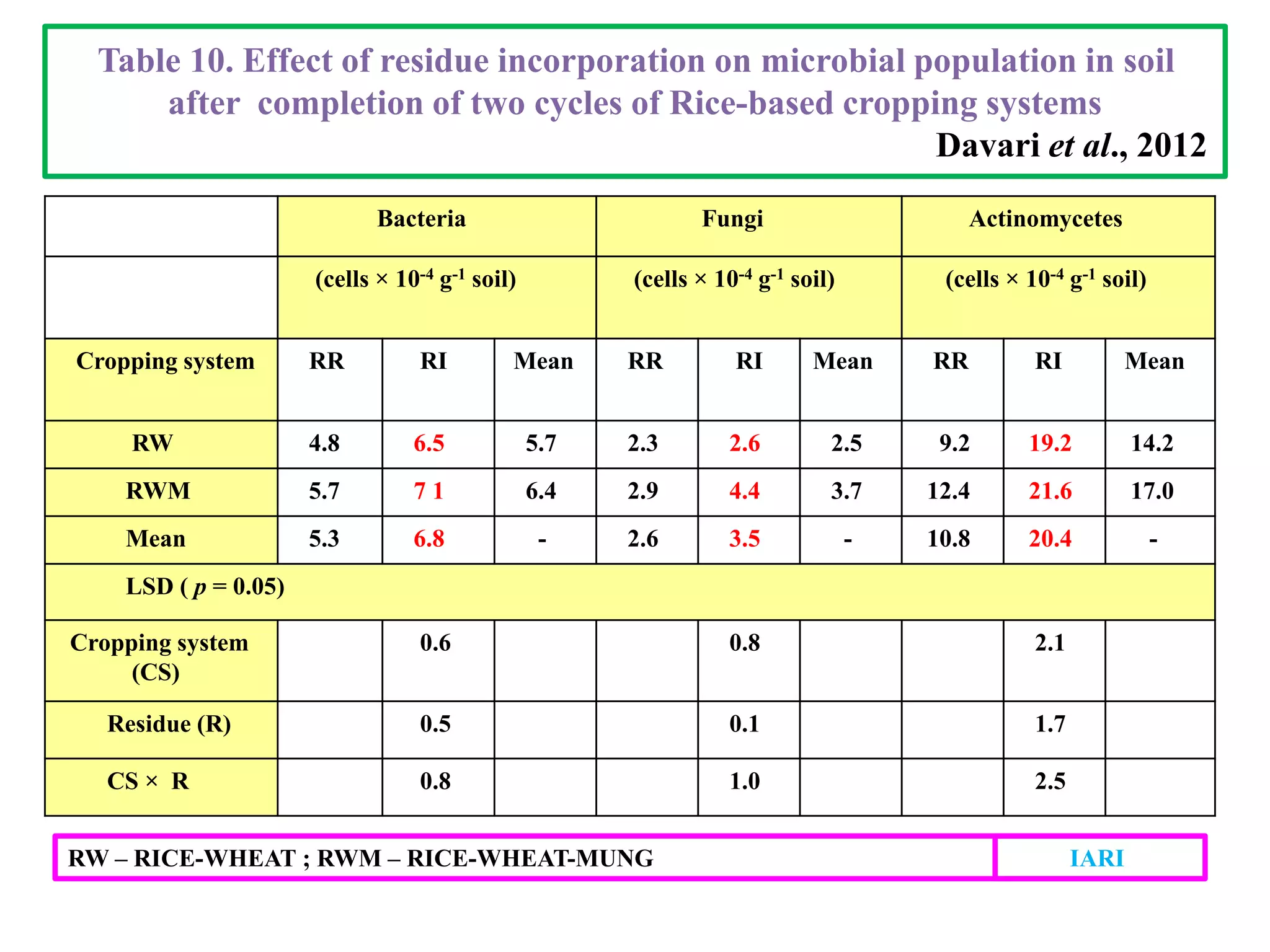

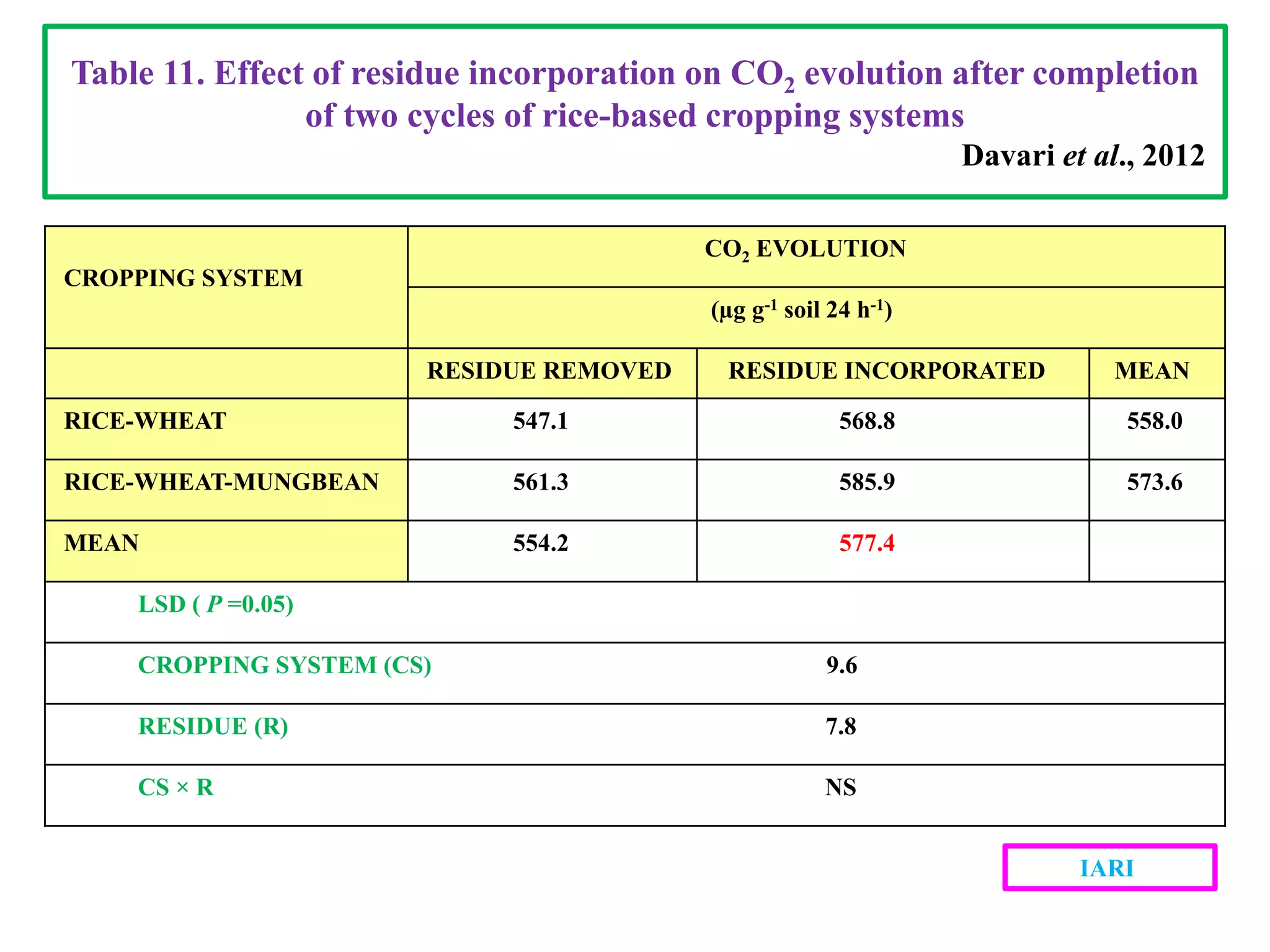

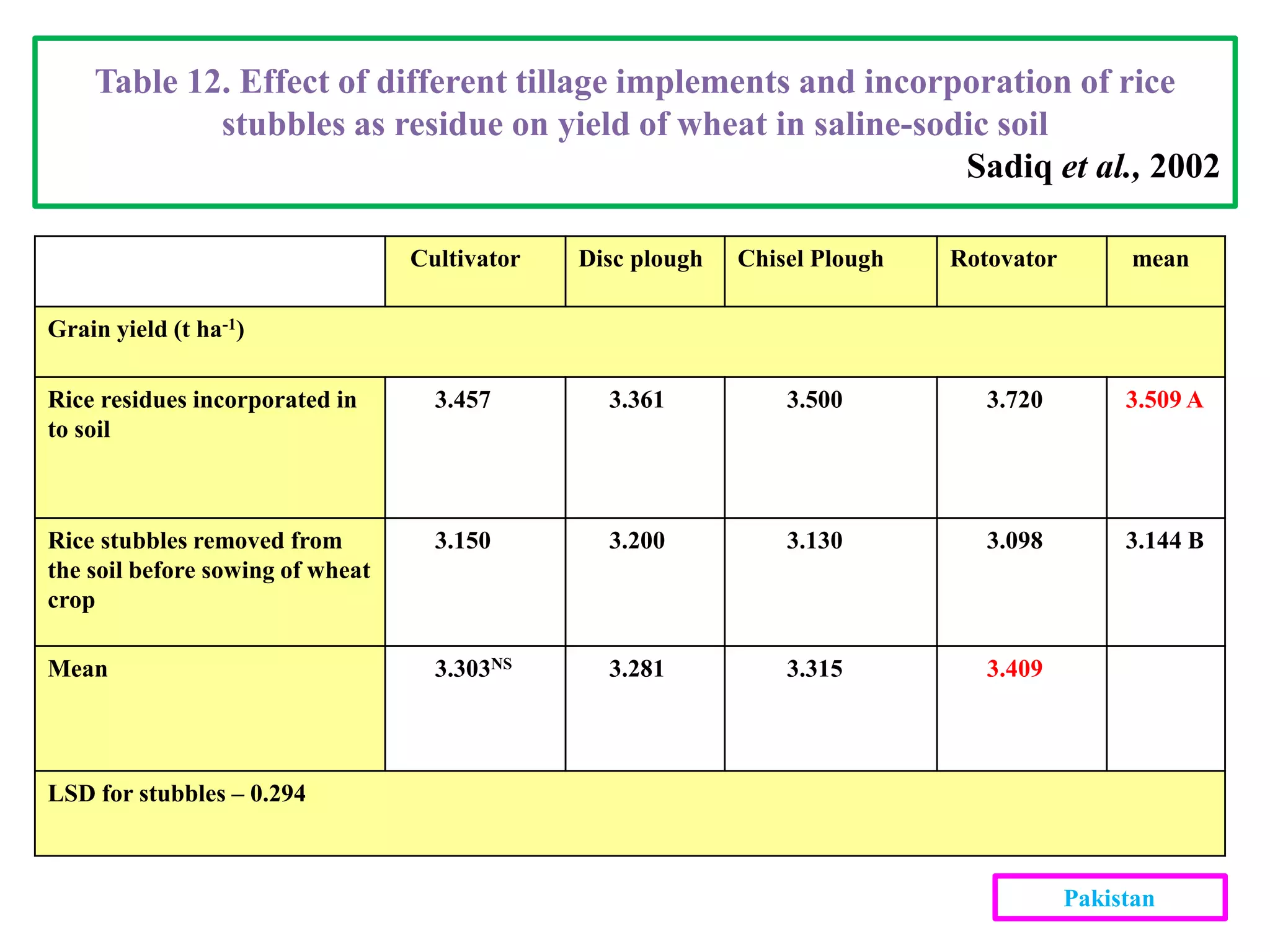

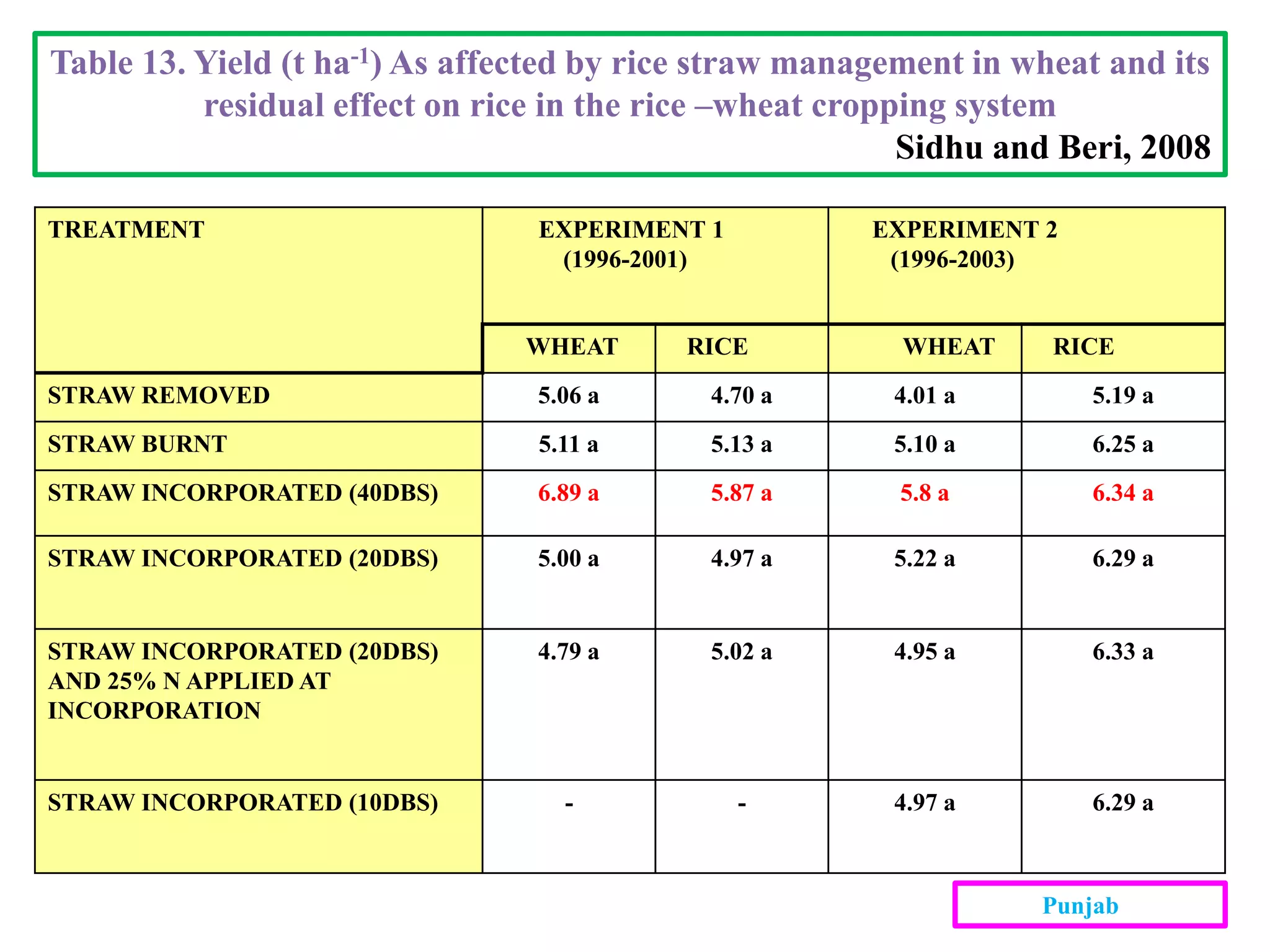

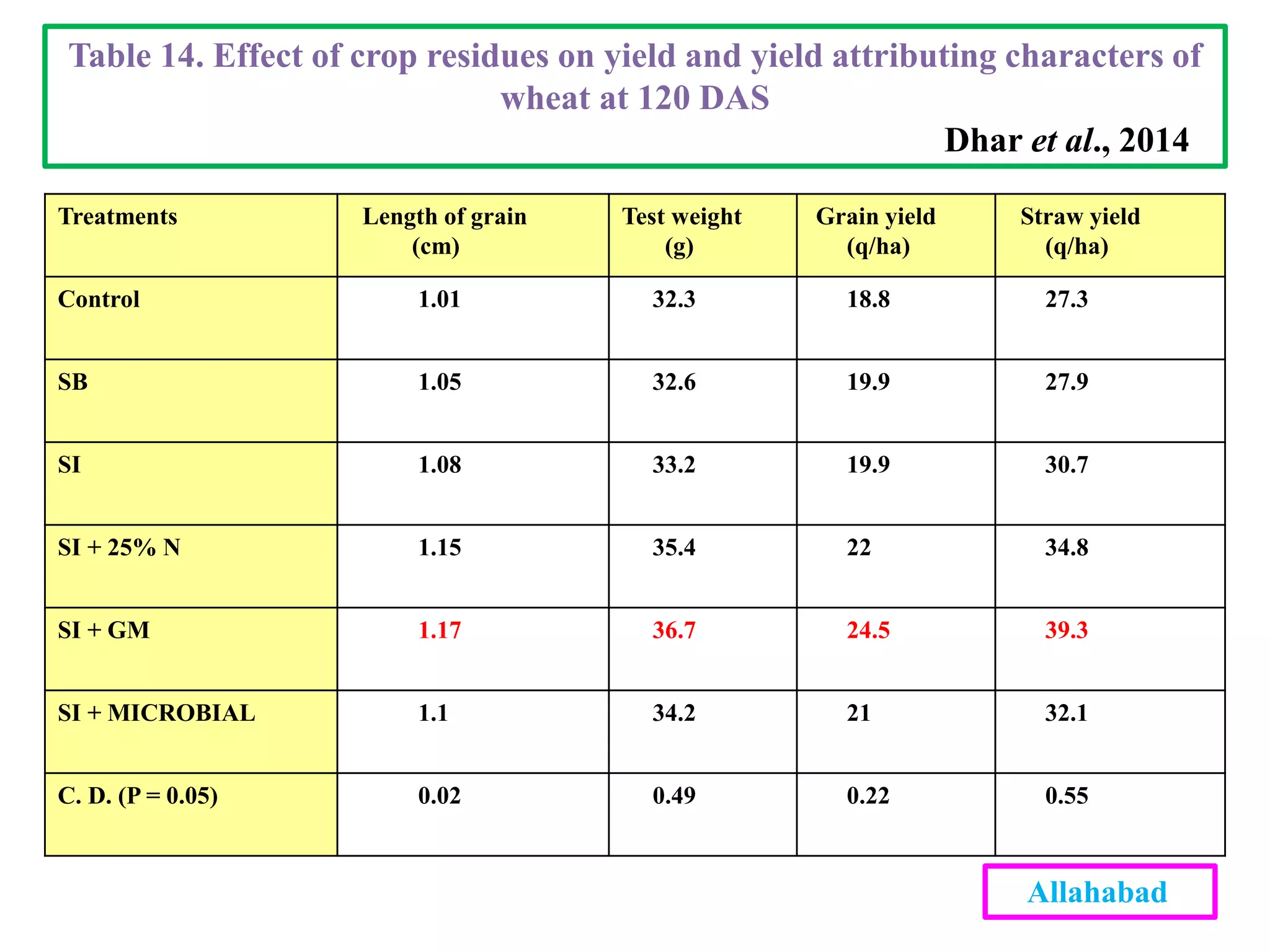

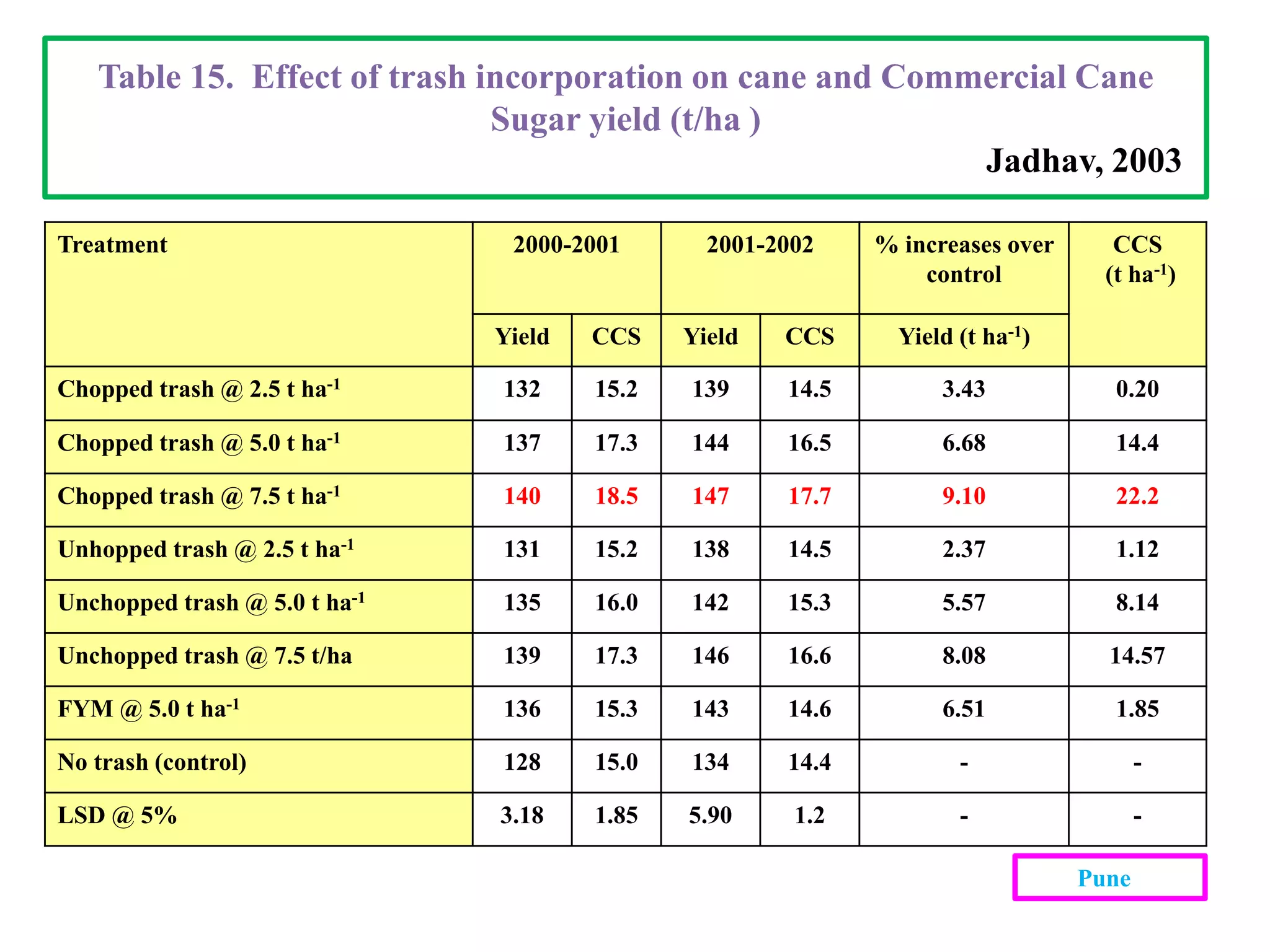

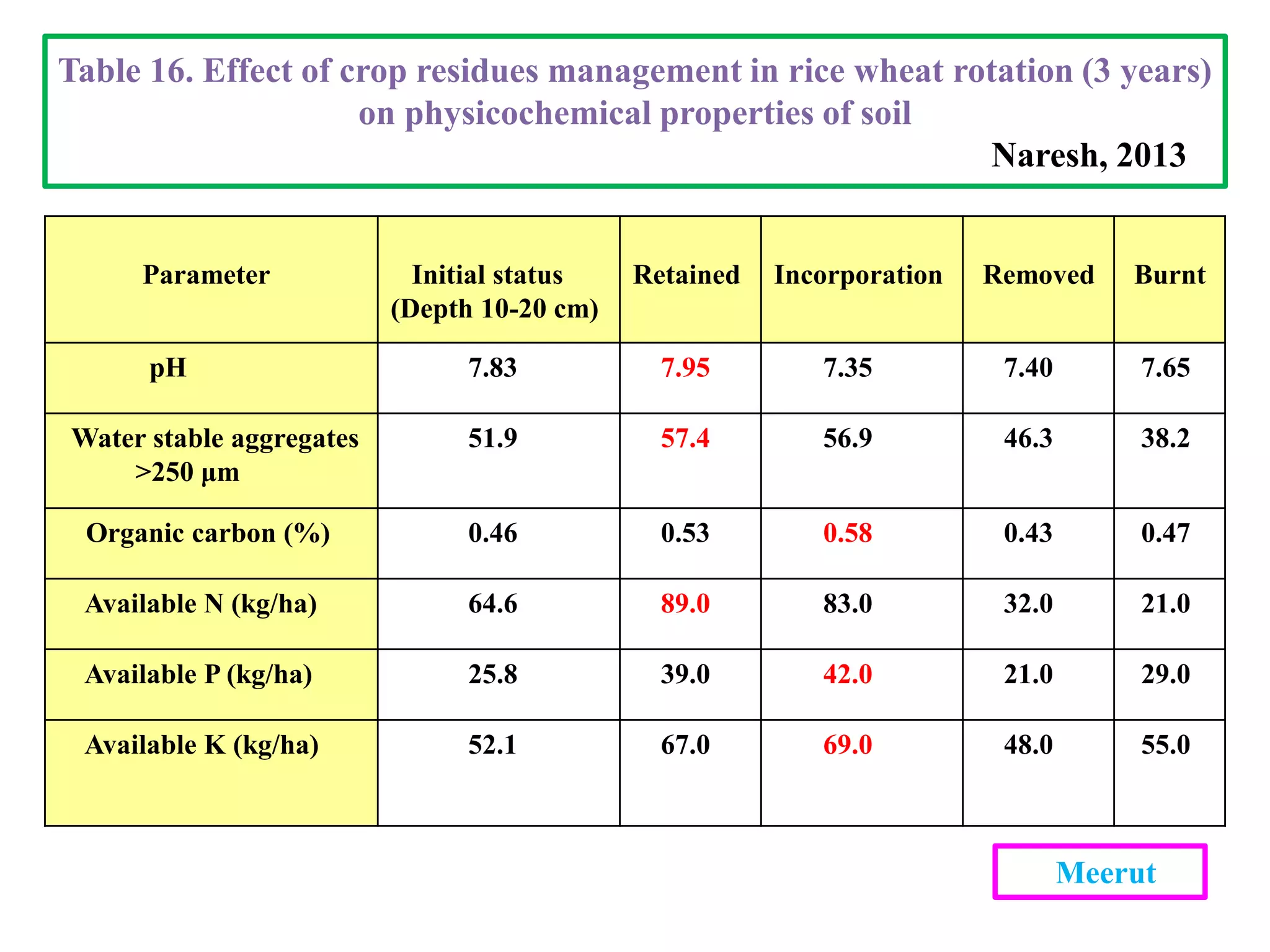

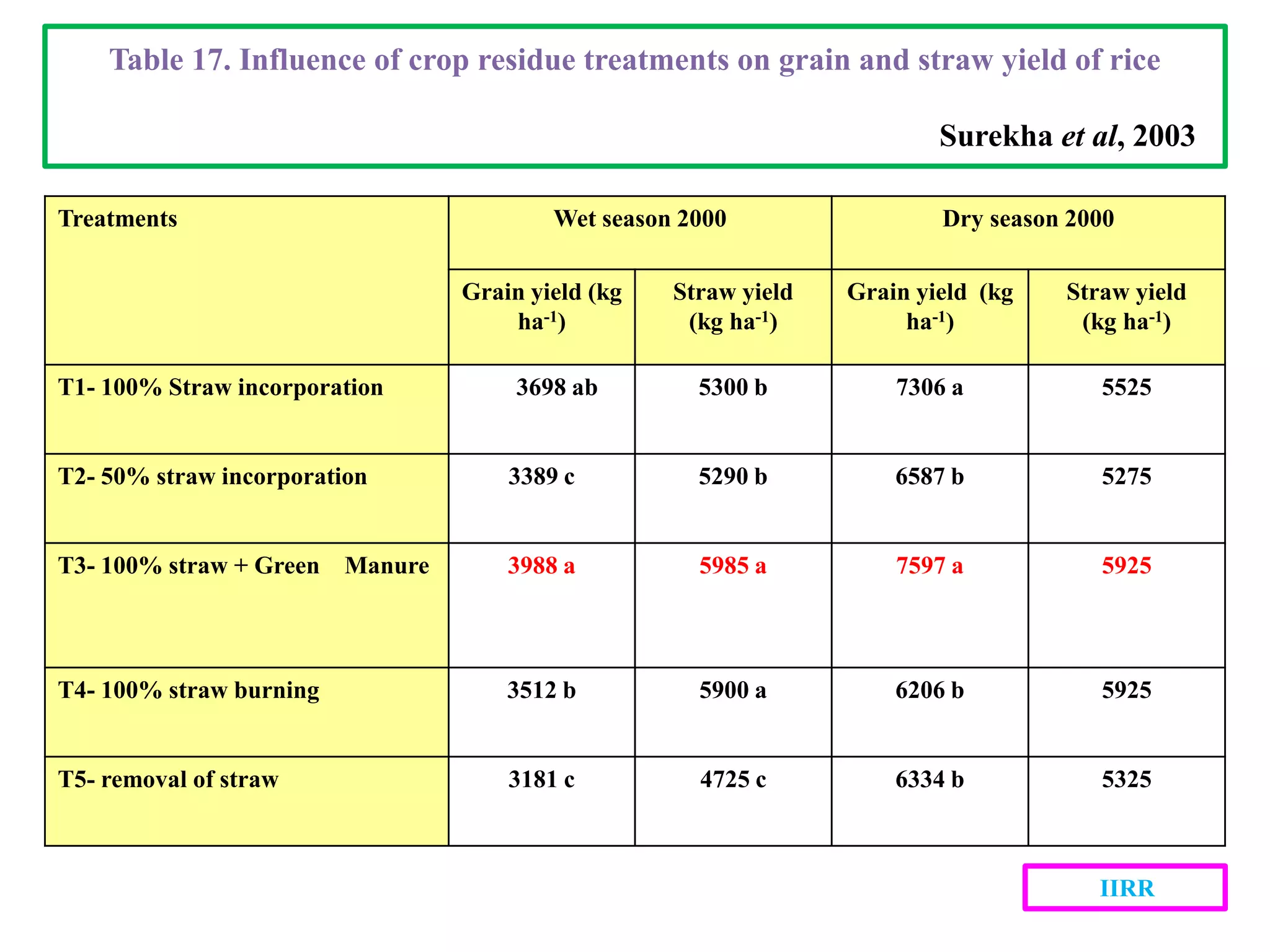

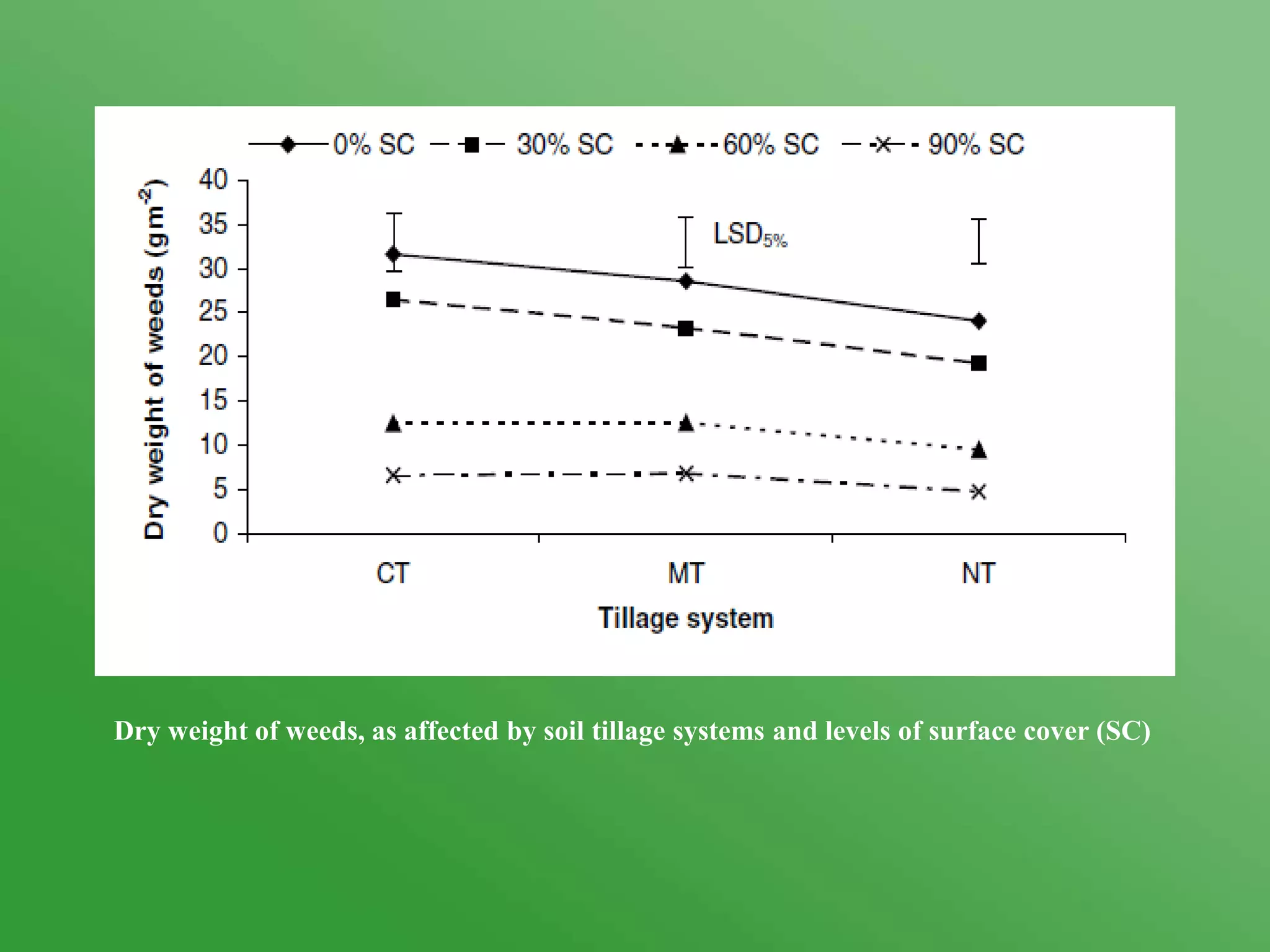

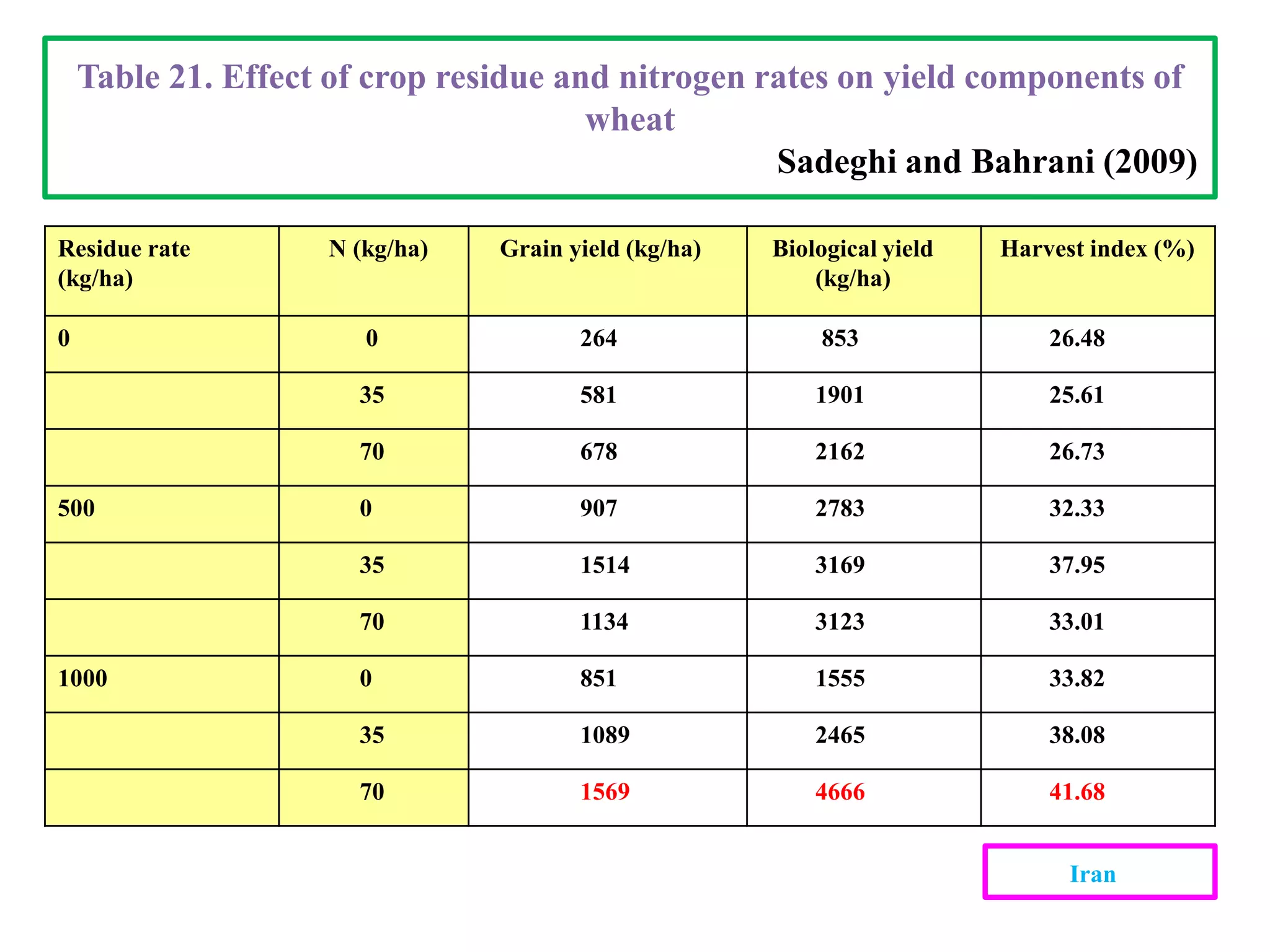

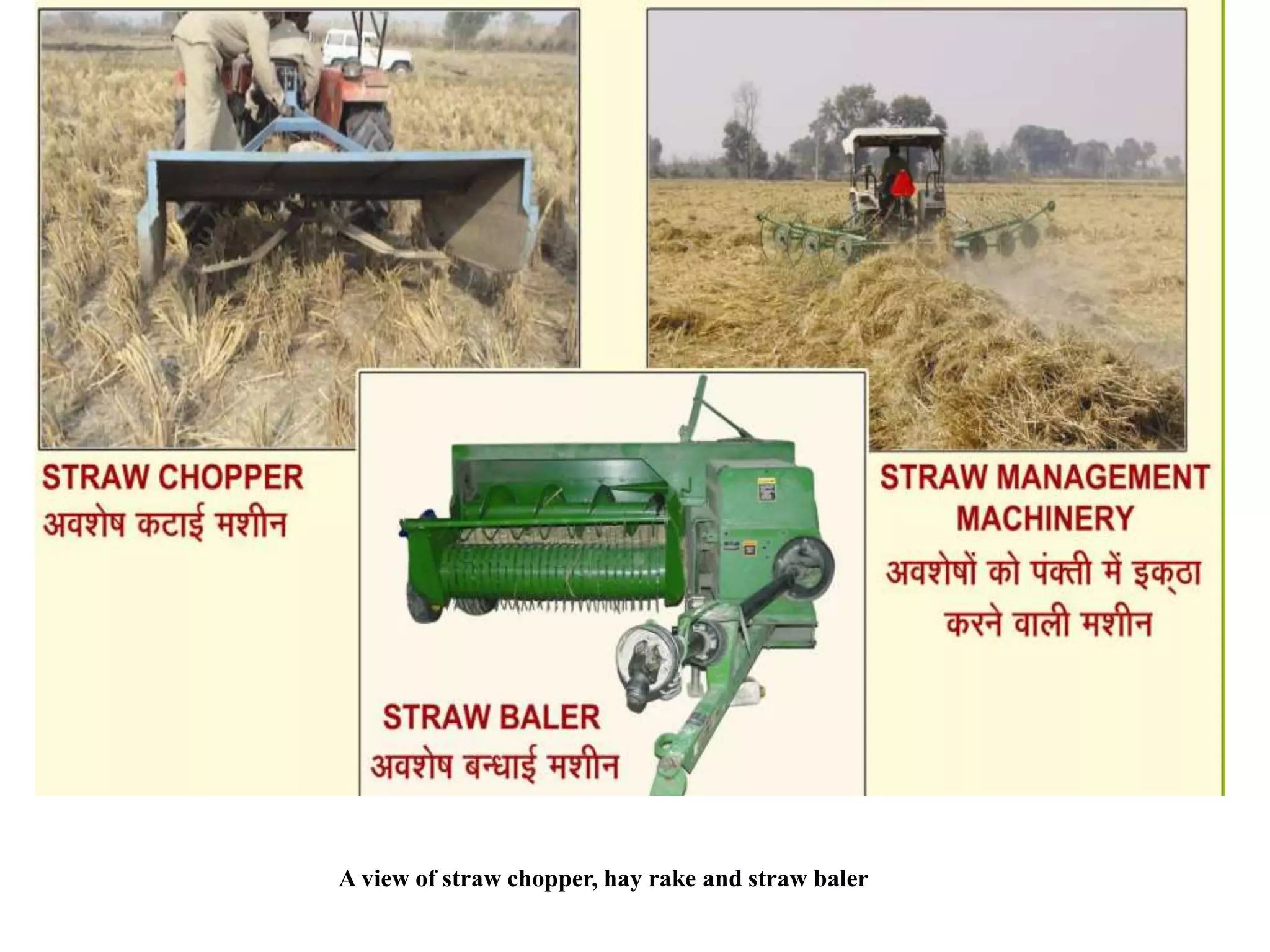

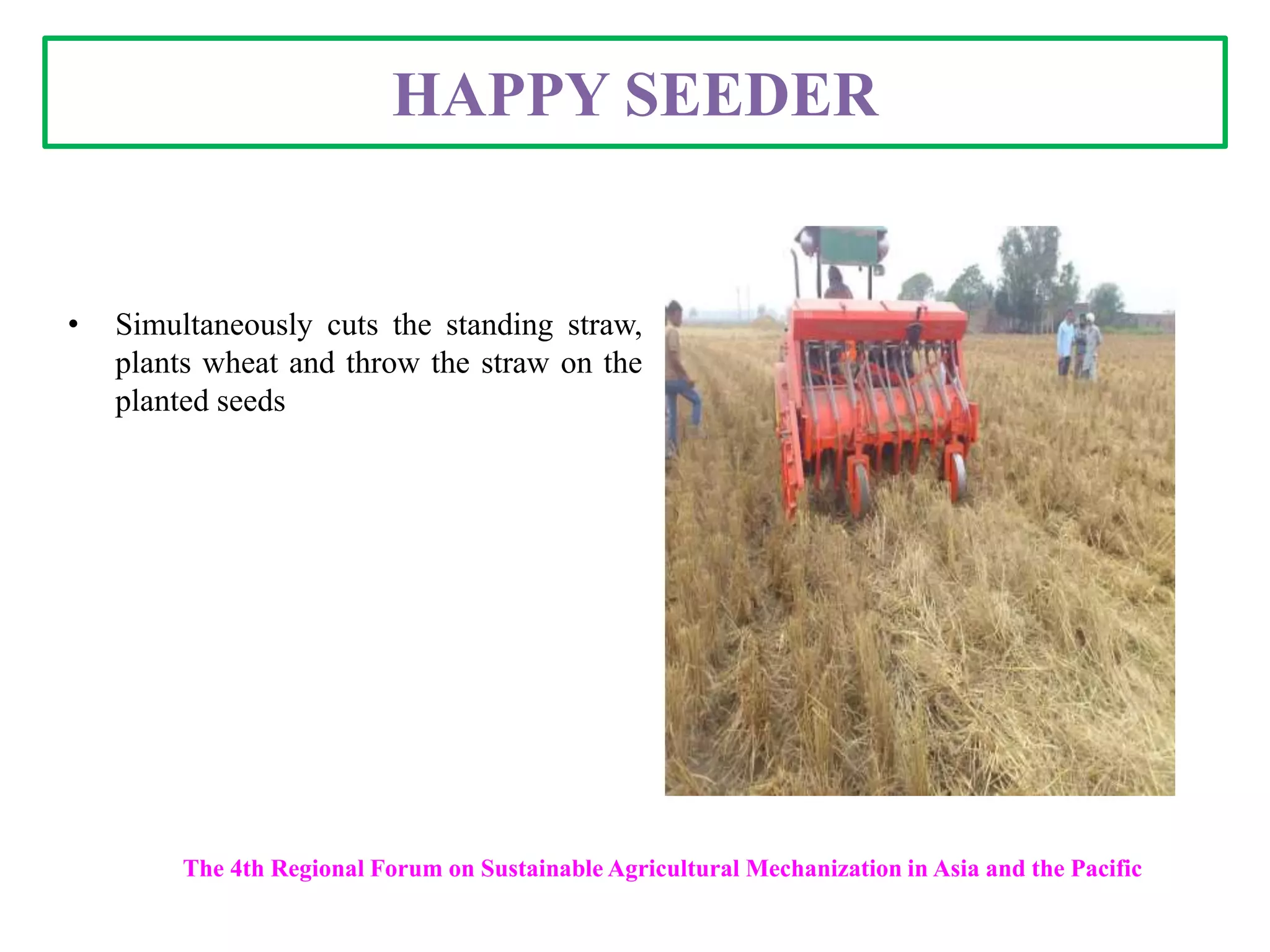

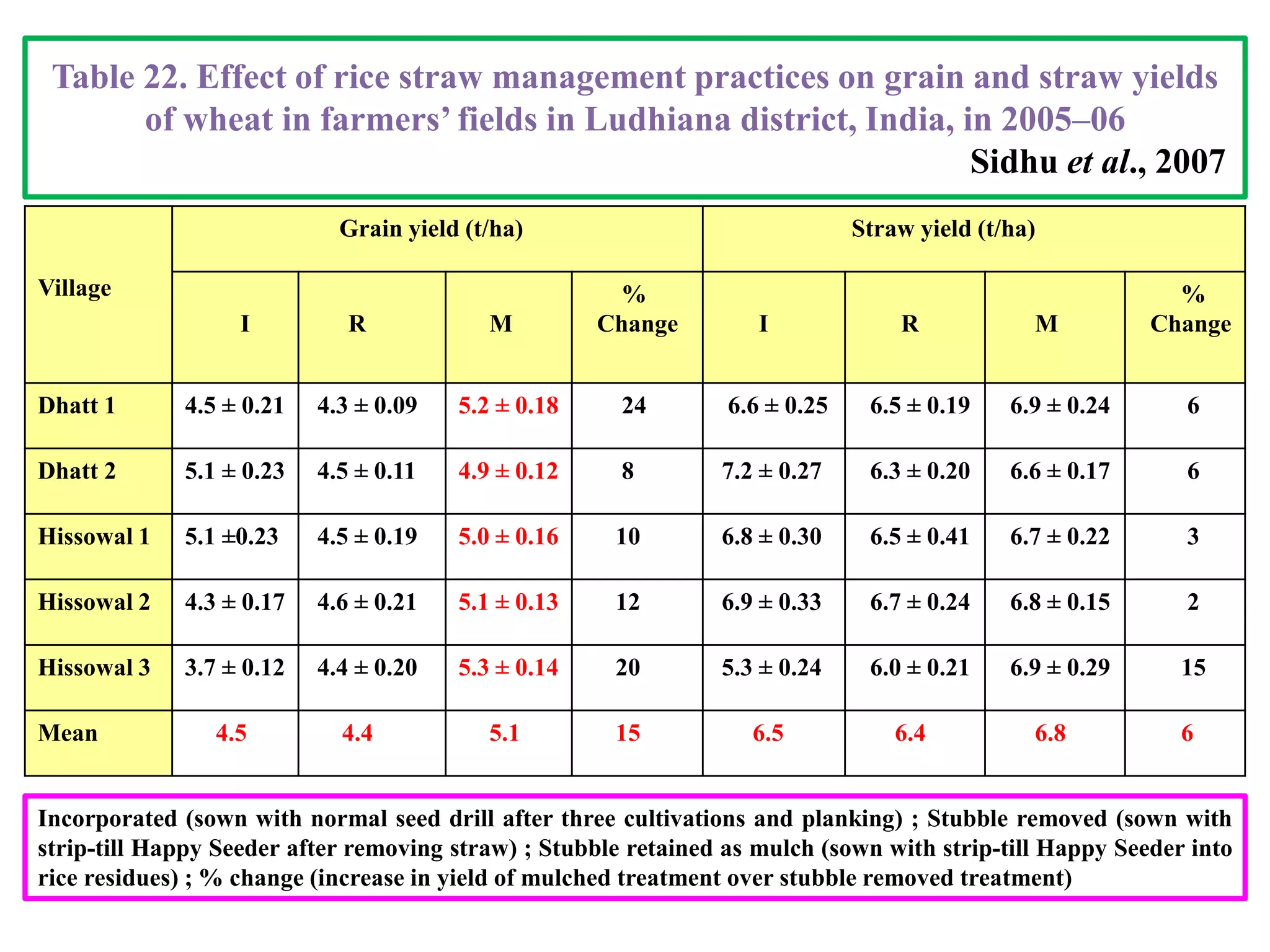

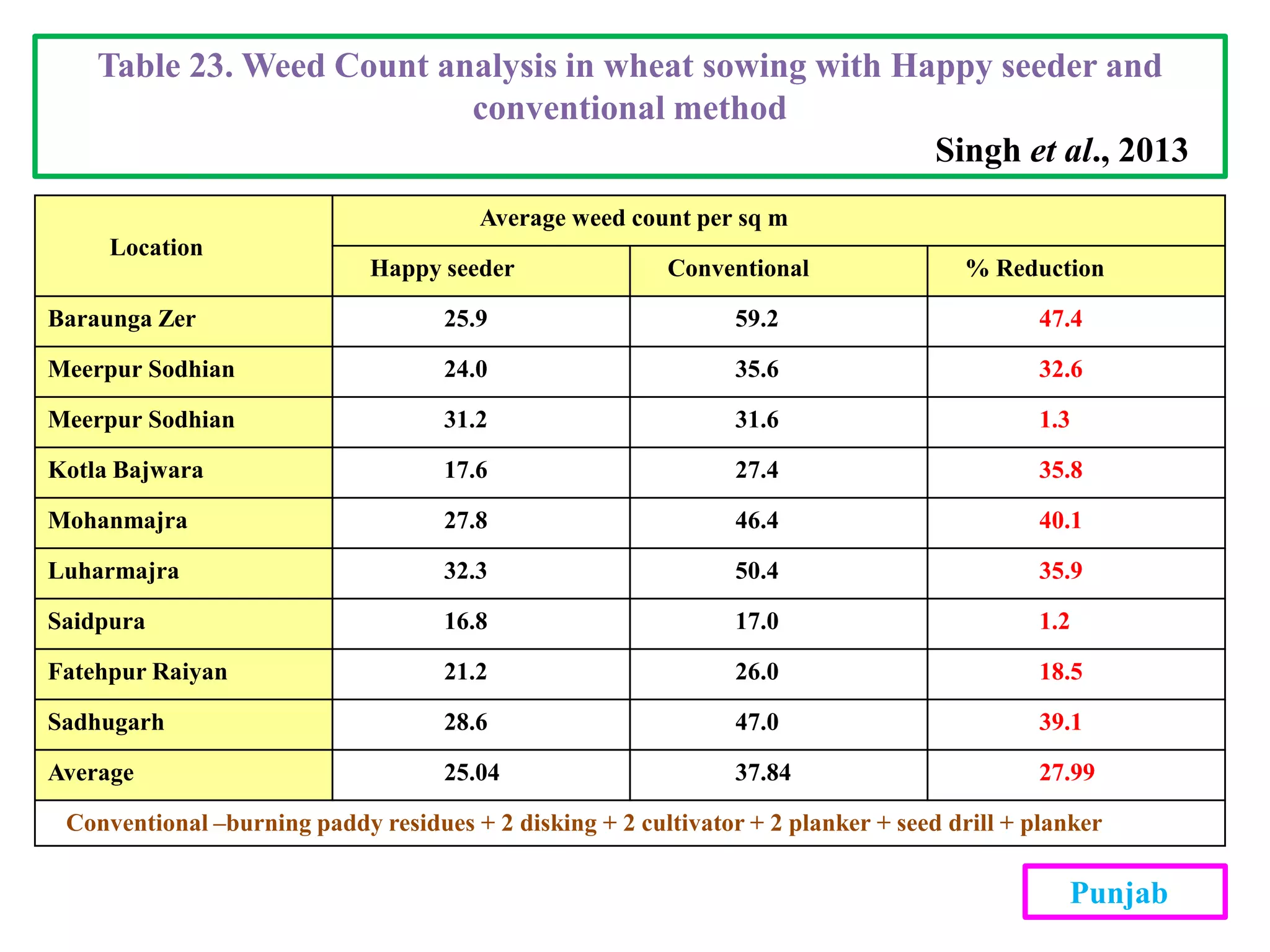

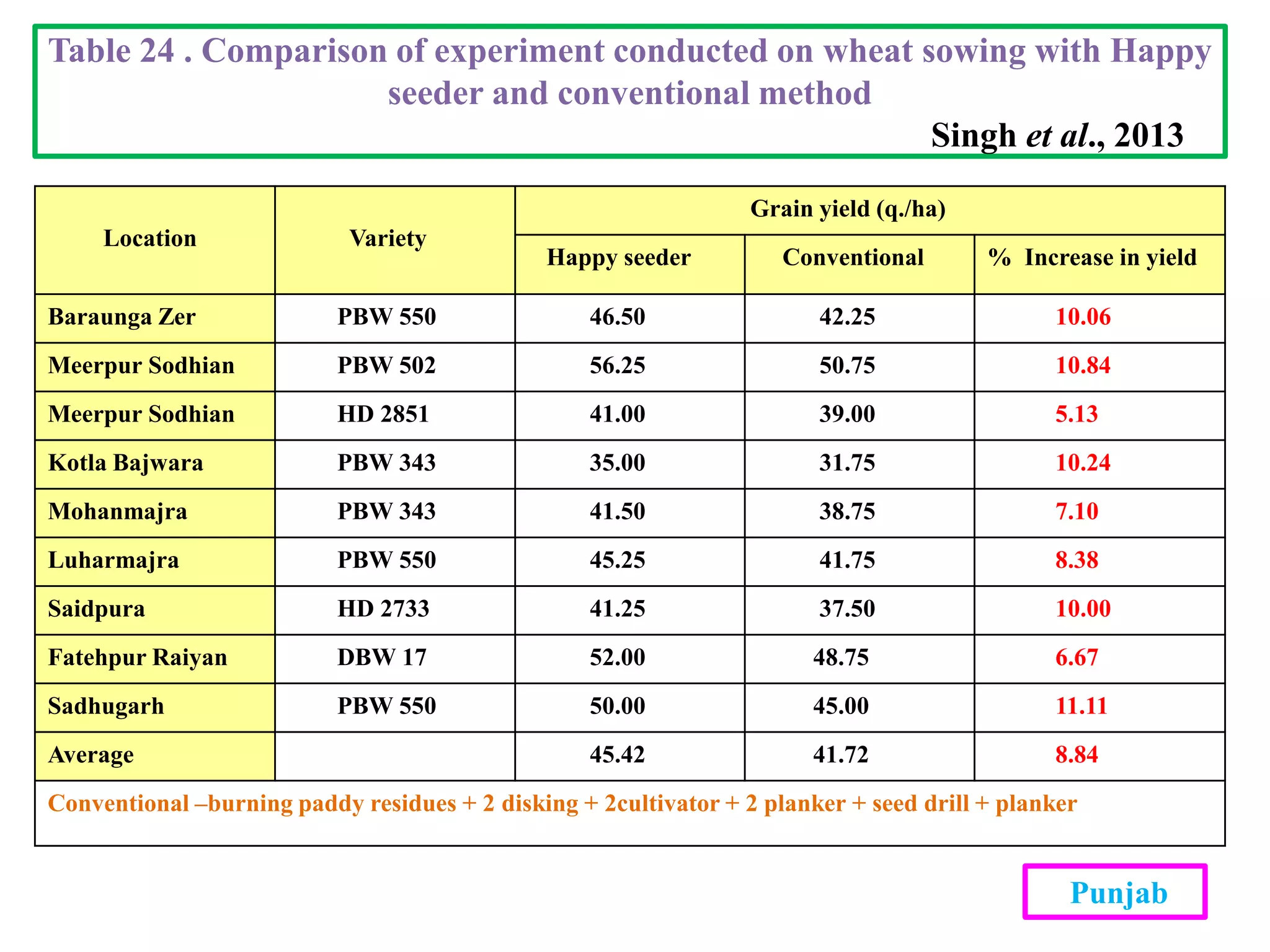

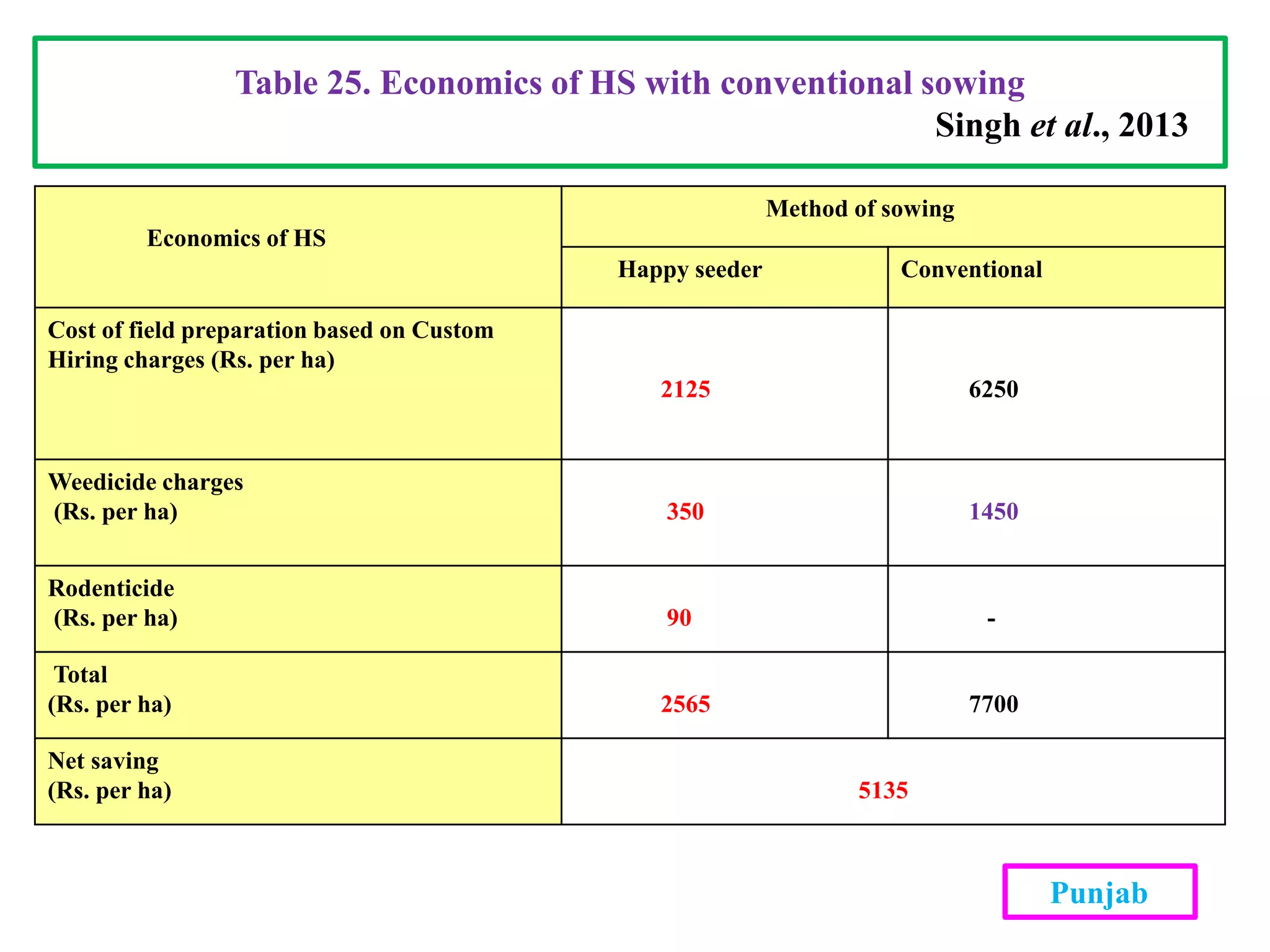

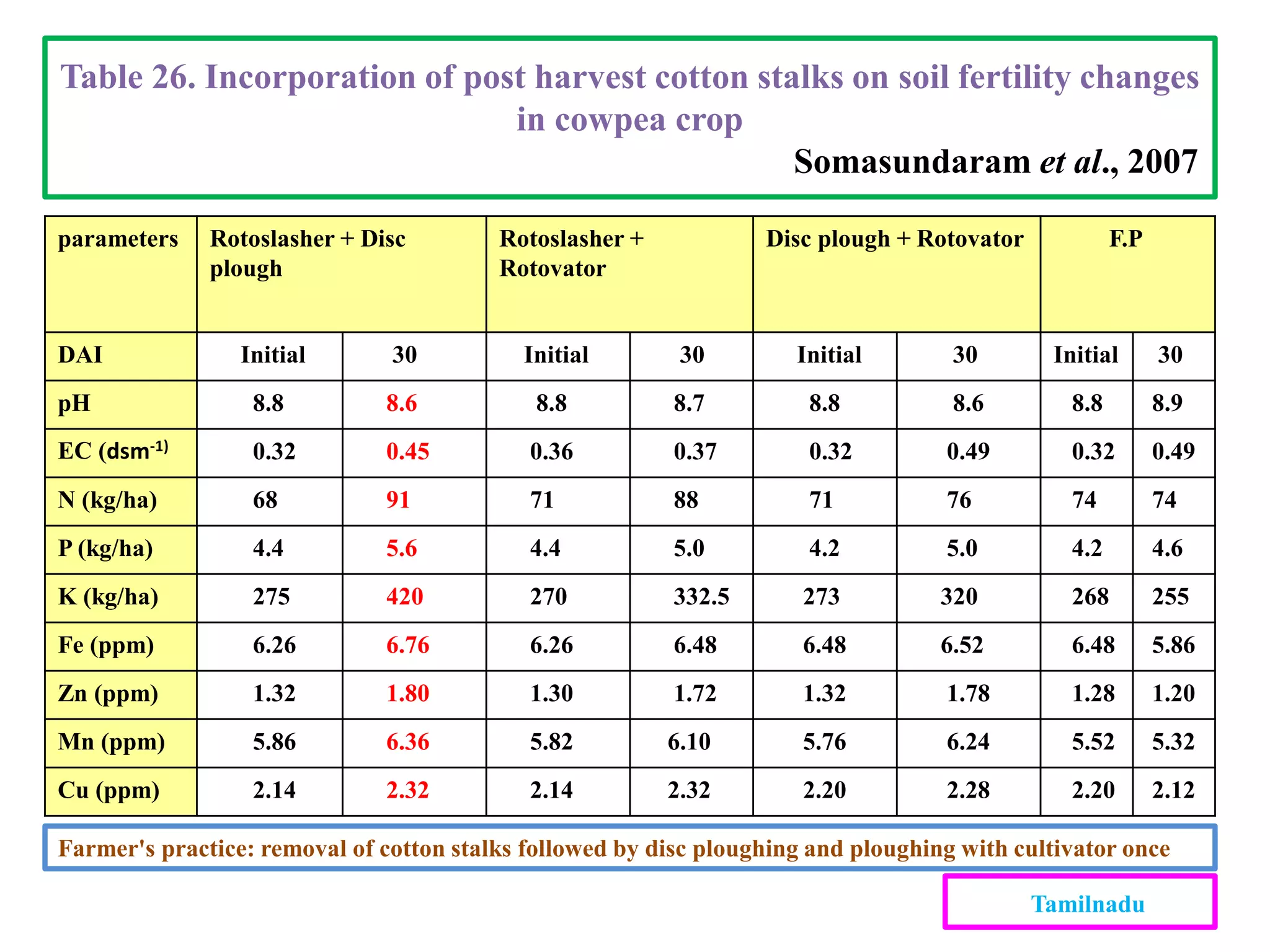

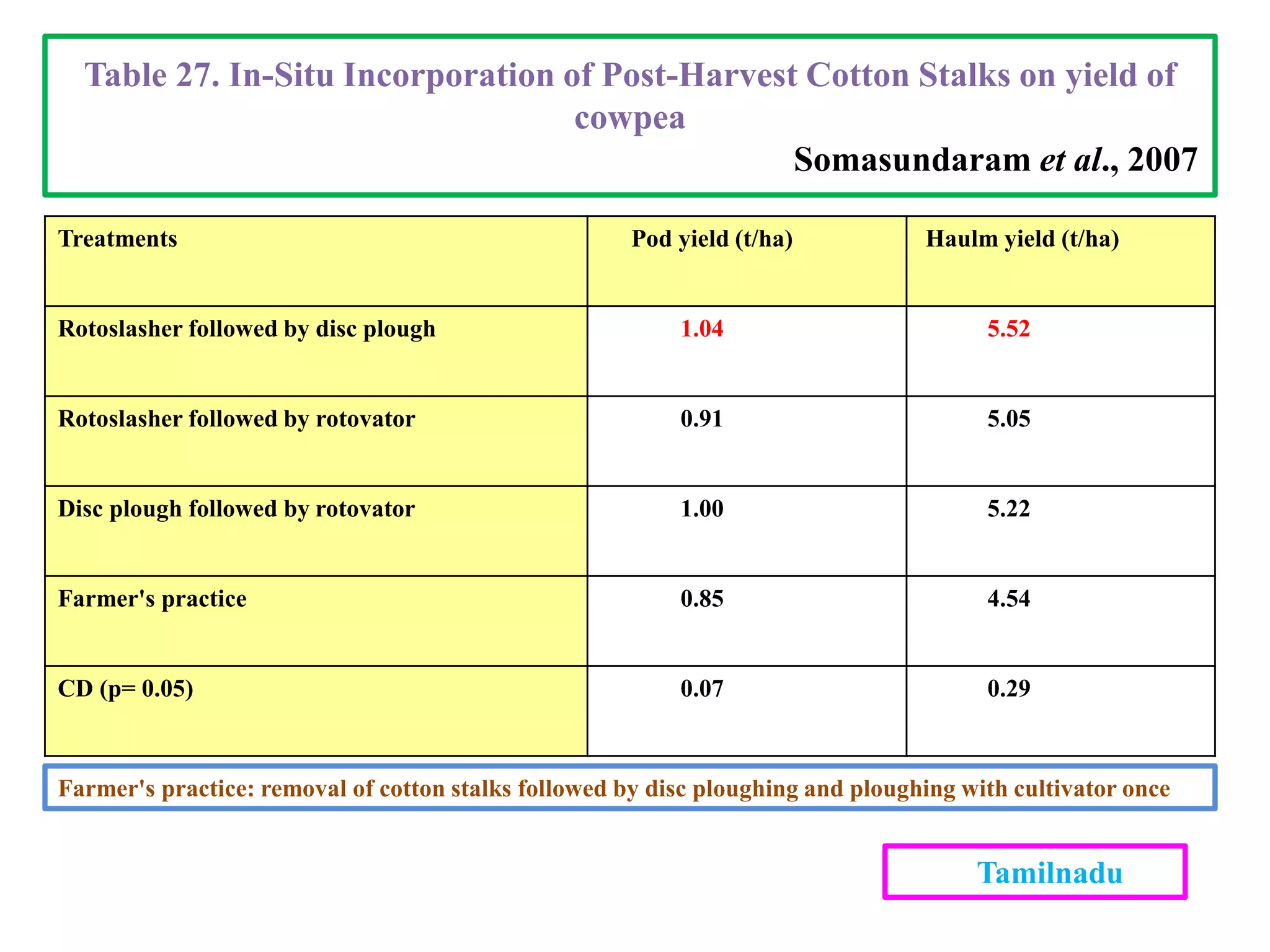

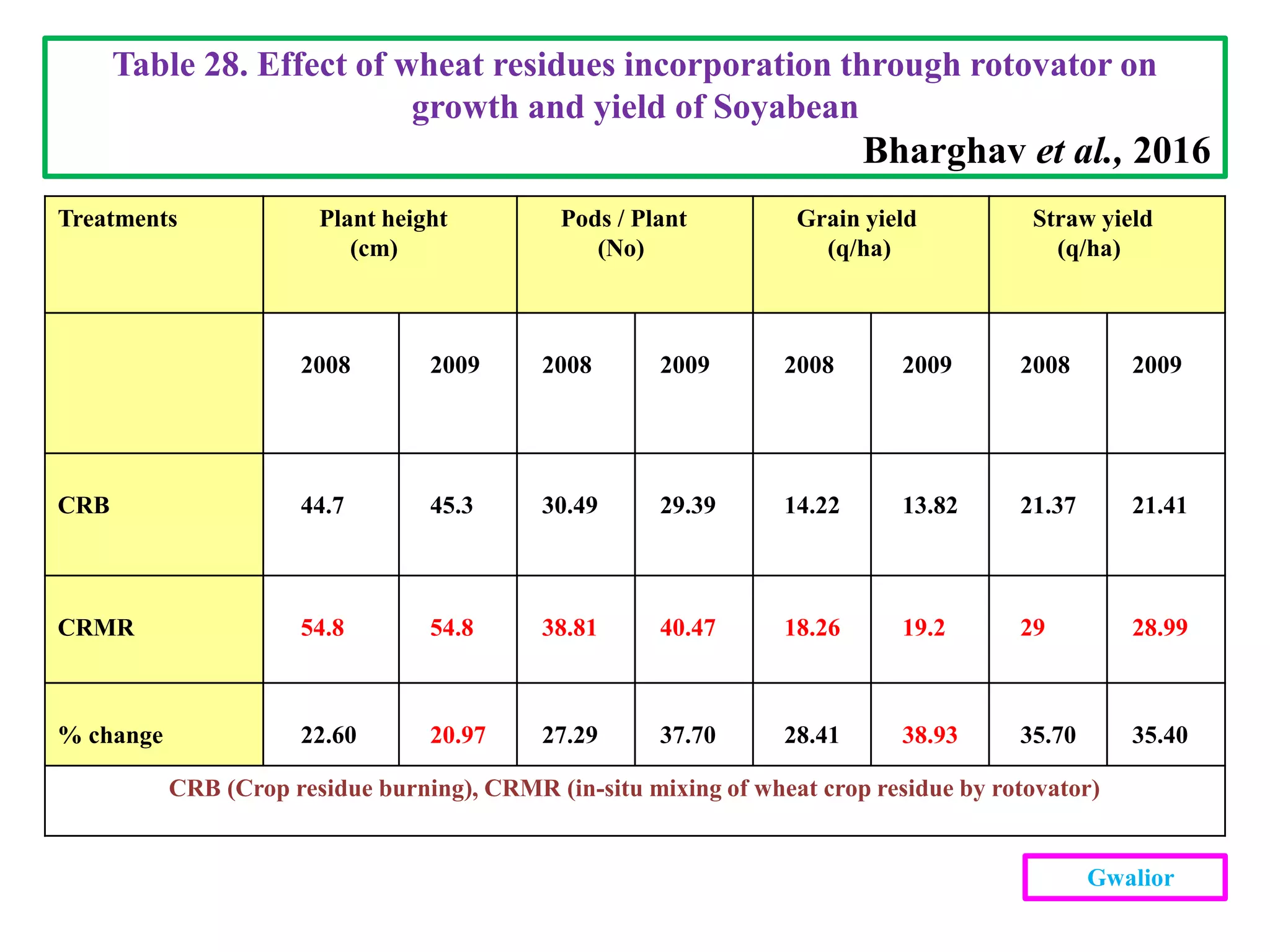

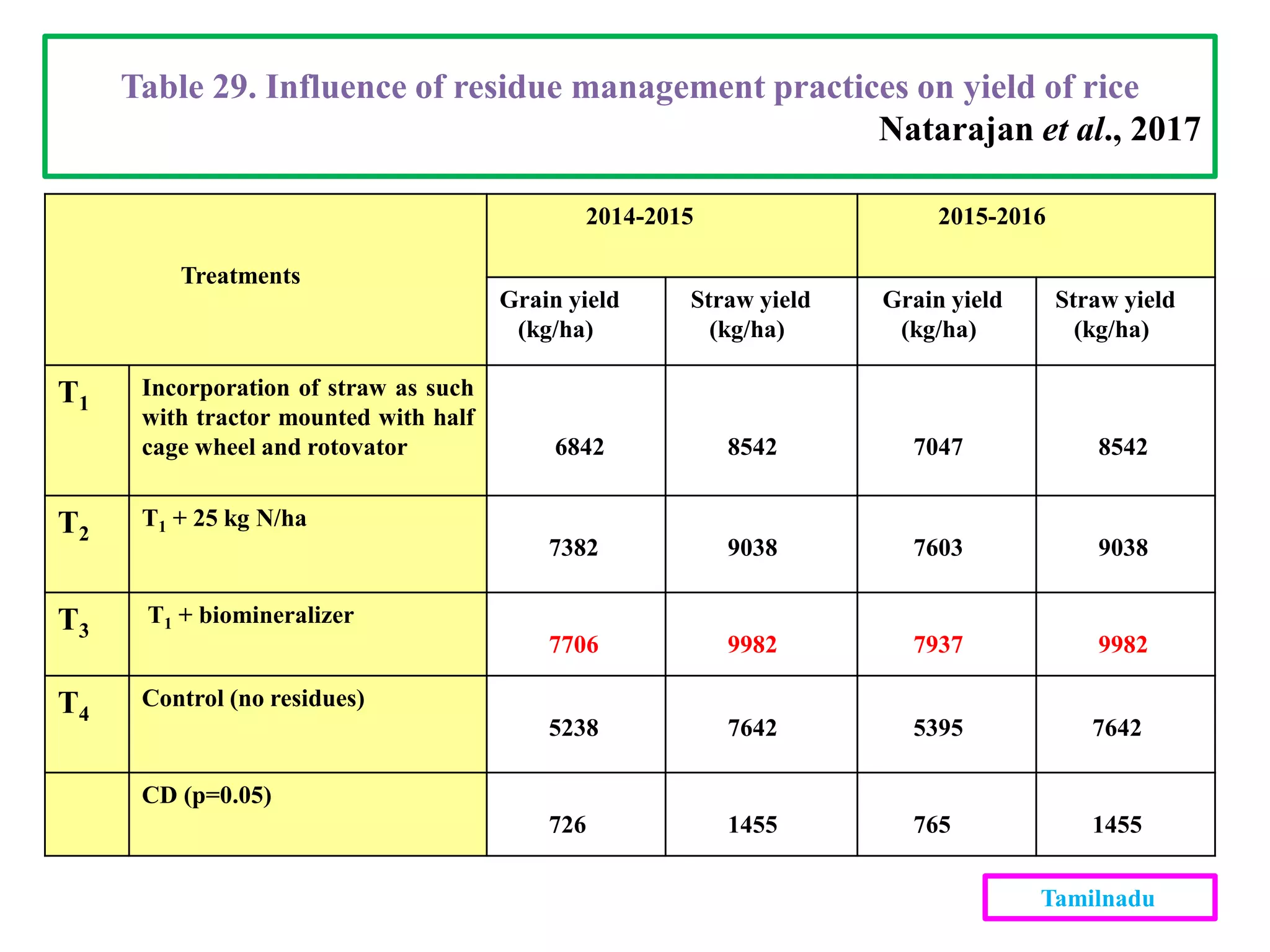

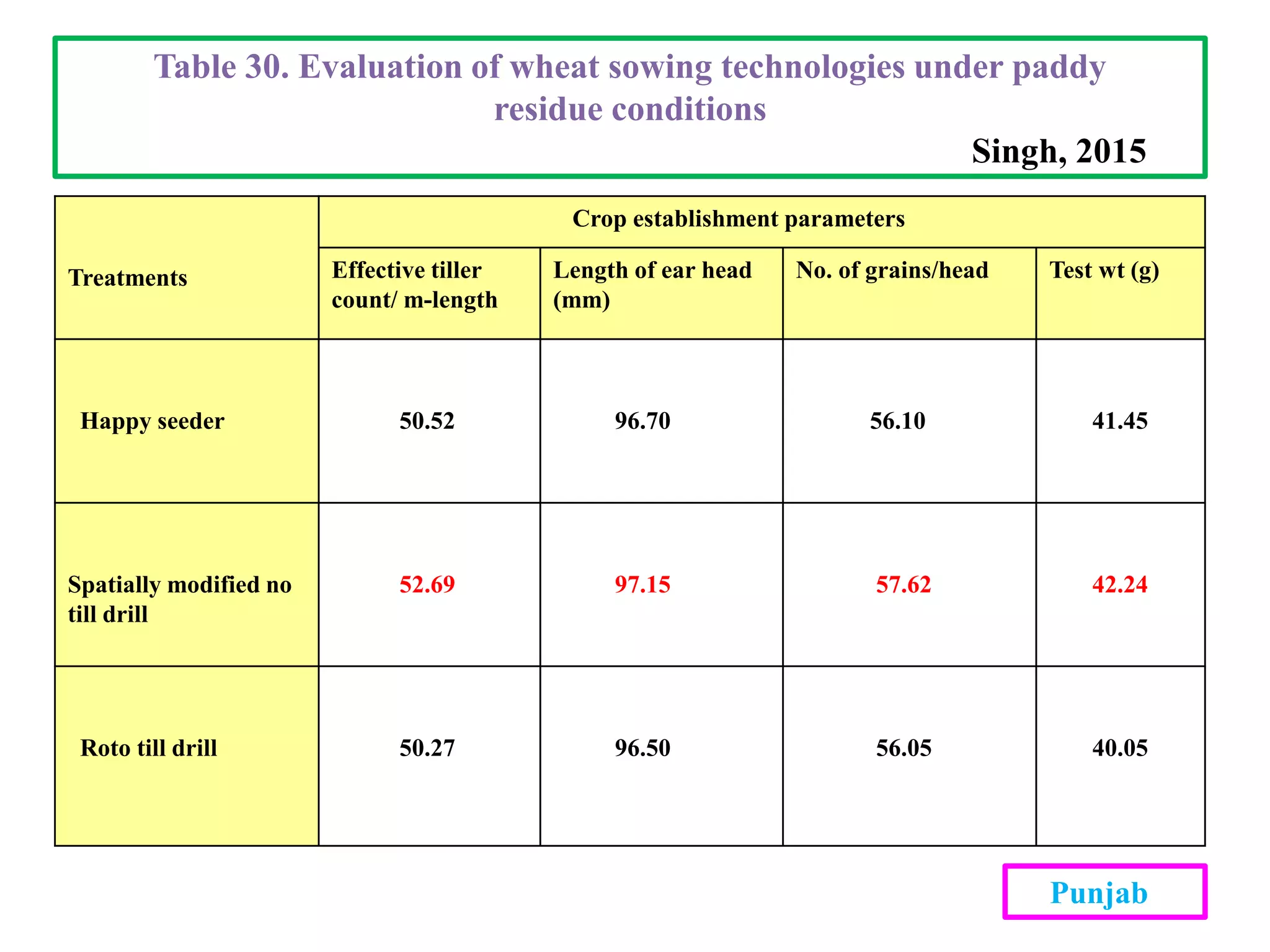

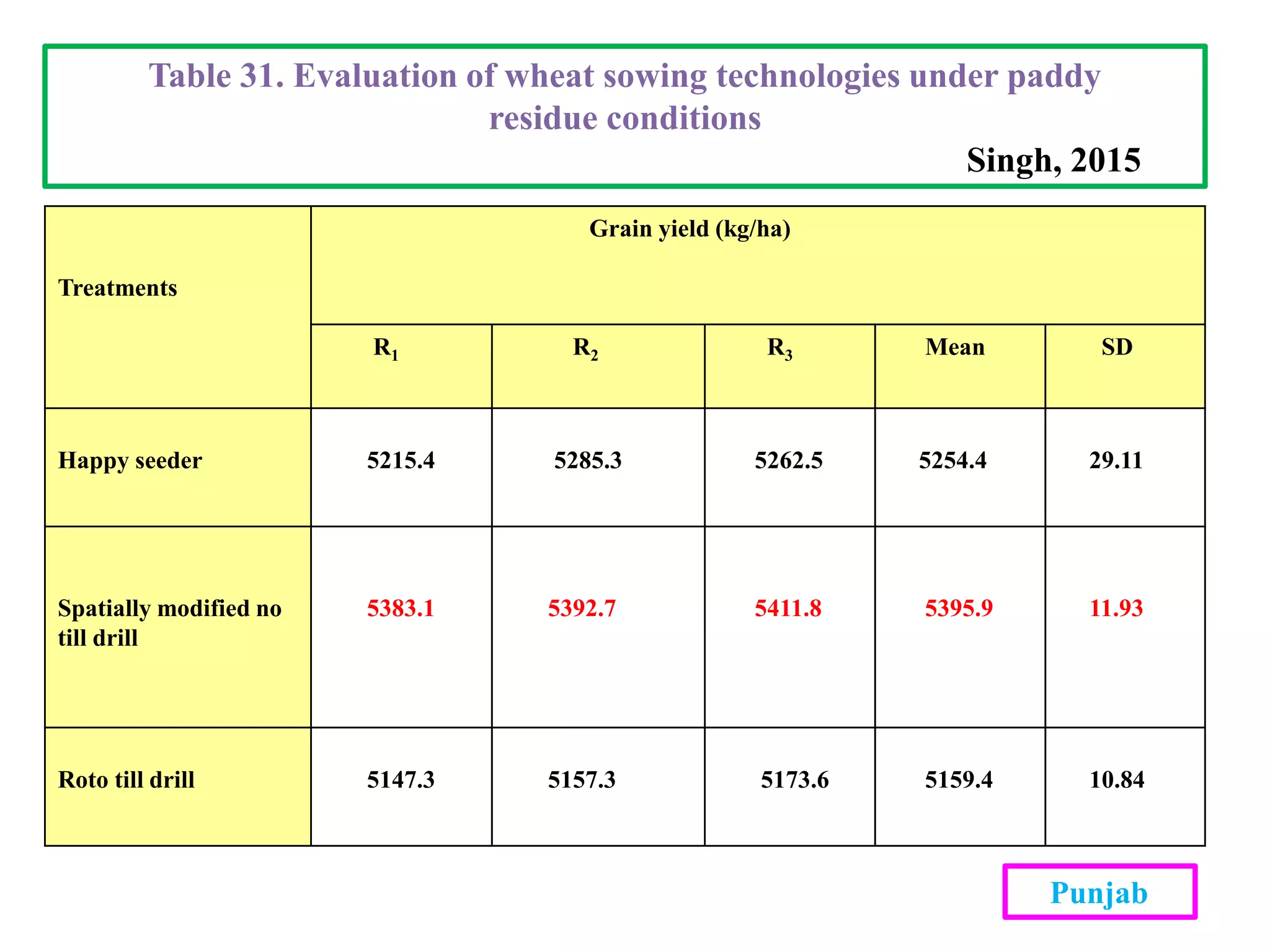

The document discusses crop residue management and smart mechanization in tropical countries, highlighting the importance of crop residues for soil fertility and overall crop production. It outlines various crop residue management practices, including the advantages and disadvantages of burning, and explores alternative uses such as animal feed, compost, and biofuels. Additionally, it presents data on crop residue generation and utilization in India, emphasizing the need for effective management strategies to enhance agricultural sustainability.