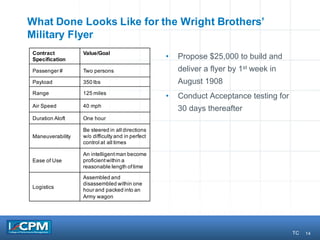

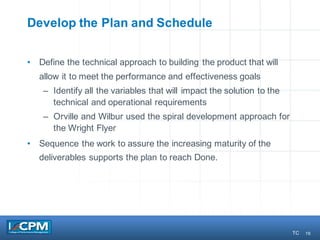

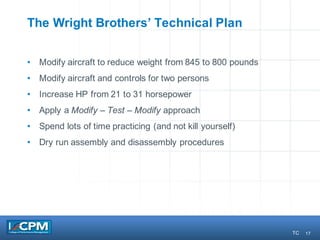

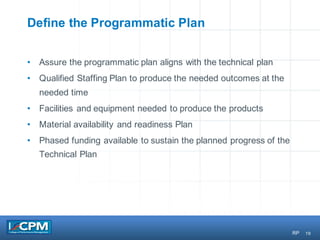

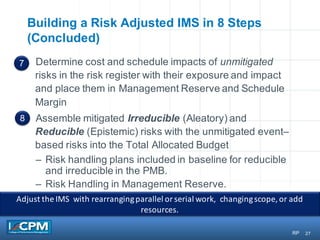

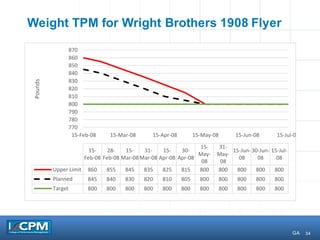

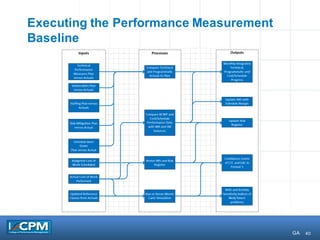

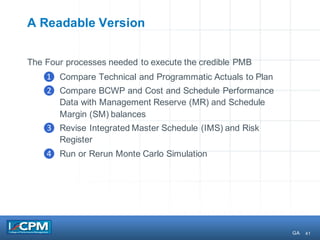

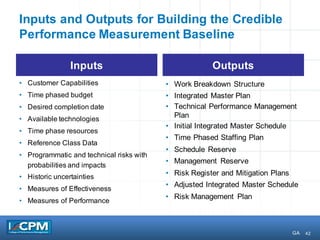

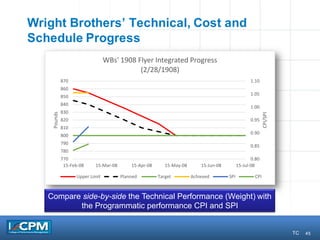

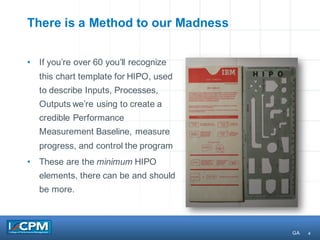

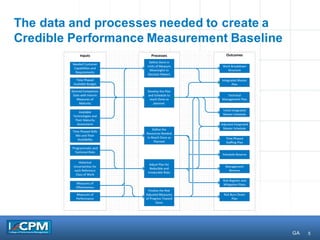

The document discusses the creation of a credible performance measurement baseline (PMB) through five core processes, utilizing the Wright brothers' flying machine as a case study. It outlines methods for defining success, developing technical and programmatic plans, adjusting for risks, and measuring progress with objective metrics. The latter sections emphasize the importance of executing the PMB by comparing actual performance against plans, and revising schedules and risk assessments based on performance data.

![9

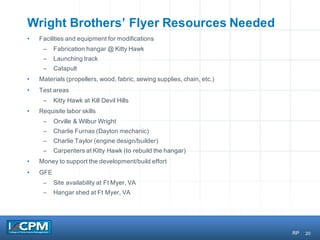

Systems Engineering Concepts Used By

The Wright Brothers [1]

SE Concept Wright BrothersActivities

Operational

Concept

Vision: clear concept of the system they were developing

MissionRequirements: powered flight for substantial timeand distance

Scenarios: recognitionof a key scenarioinvolvinglateral control during flight

Define the System

Boundary

Understoodthe need for the pilot to be part of the system

Objectives Definitionof distanceand time objectives

Derived

Requirements

Horsepower and weight of the engine

Thrust of the propellers

Requirements

Management

Managed weight requirement of the engine carefully

Functional

Analysis

Understood the functions of the airplane, which drove their design process

Further understood the functions of the propulsionsubsystem

Physical

Architecture&

Interfaces

Matched the physical architecture tothe functions of the airplane

Interfaces between the pilot and the control surfaces

Interfacebetween the engine and propellers TC](https://image.slidesharecdn.com/alleman-coonce-pricefinalv1-160202214942/85/Credible-Plans-Integrated-Reporting-and-Control-Systems-9-320.jpg)

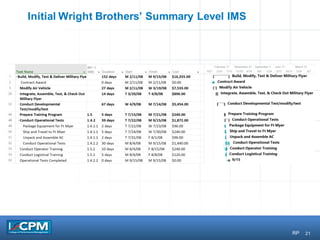

![10

Systems Engineering Concepts Used By

The Wright Brothers [1]

SE Concept Wright BrothersActivities

Prototypes and

Testing

Built a successfullymorecomplex set of gliders before building the airplane

First airplane was successful,due to the series of gliders and kites

Employed sophisticatedtestingwitheach prototype, atypical of others at the

time

Trade-Off

Decisions

Design favoredcontrol of the airplane over stability

Test System

Extensiveevenduring glider tests

Allowed problem identificationand solvingduring all test phases

Created wind tunnel to address discrepancy between their test data and the

literature

Included the careful selectionof the test site

Included in the first airplane

Verification

Best illustratedby testingof the engine to determine whether it met its

requirements

Validation The final test that proved flight was possible

Team Activities Two brothers formed a design-build team TC](https://image.slidesharecdn.com/alleman-coonce-pricefinalv1-160202214942/85/Credible-Plans-Integrated-Reporting-and-Control-Systems-10-320.jpg)