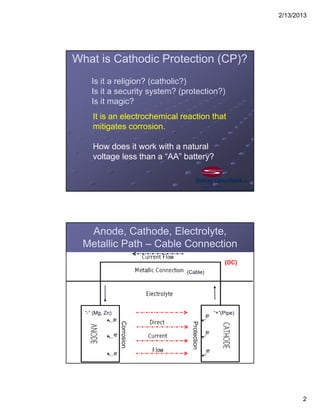

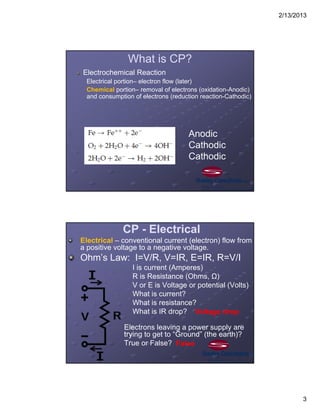

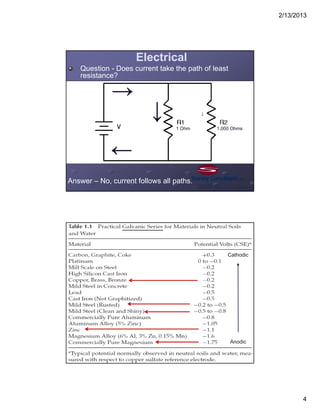

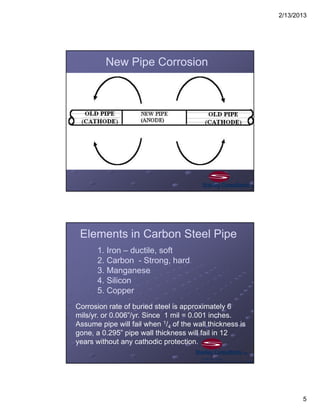

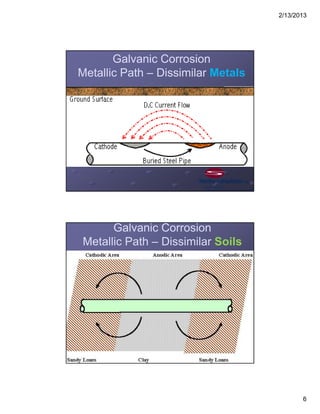

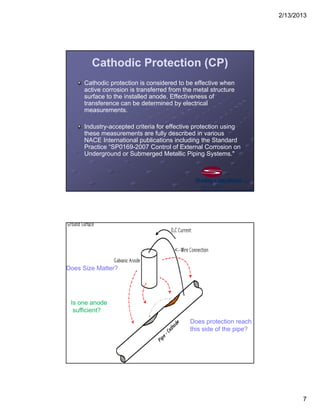

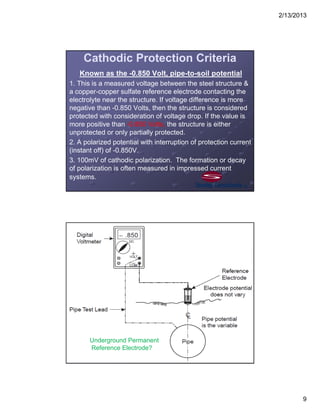

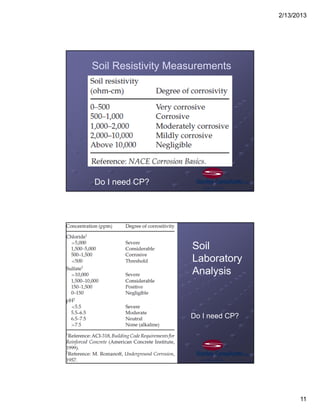

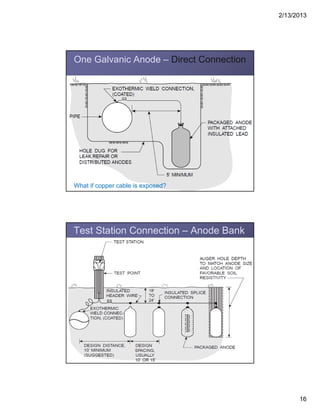

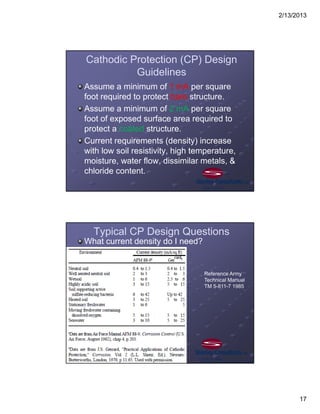

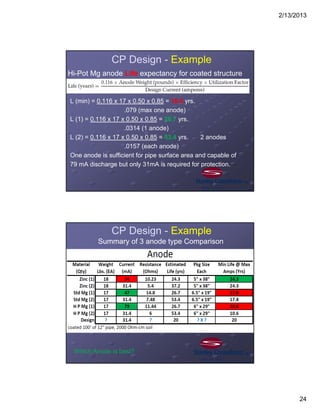

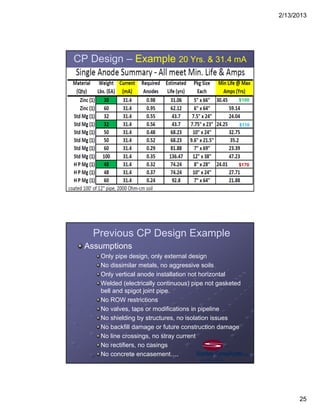

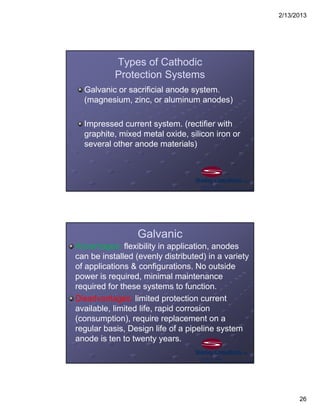

This document provides an overview and agenda for a presentation on modern cathodic protection for piping. It discusses corrosion basics, criteria for cathodic protection, design considerations for galvanic anode systems, and types of cathodic protection systems. The document uses examples to demonstrate how to design a cathodic protection system using galvanic anodes to protect an underground coated steel pipe over 20 years. It compares zinc, standard magnesium, and high-potential magnesium anodes in terms of current output, life expectancy, and cost.