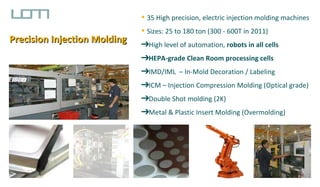

The document provides information about LOM / Perlos Mexico Reynosa, a manufacturing facility in Reynosa, Mexico. It details the facility's capabilities such as precision injection molding, painting, and assembly lines. The facility focuses on producing precision and decorated plastics for devices, automotive, and medical industries and maintains certifications for quality, health and safety, and environmental standards.