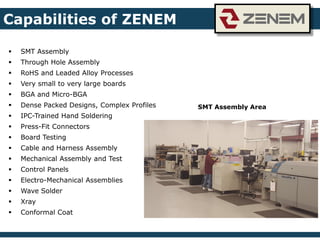

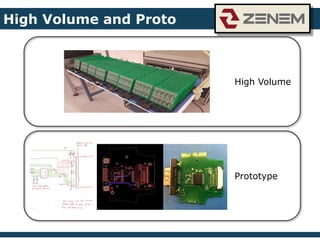

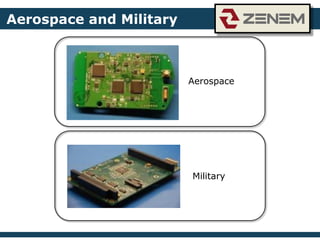

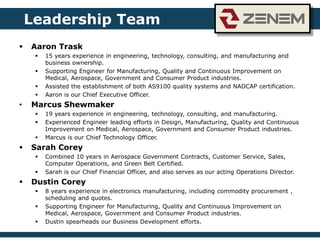

ZENEM Corporation provides electronic manufacturing services such as quick-turn prototyping, production, and full system assembly. They have automated assembly lines and equipment for SMT placement down to 0201 components as well as through-hole assembly. Notable customers include companies in aerospace, automotive, medical, and consumer electronics. The leadership team has over 80 years of combined experience in engineering, manufacturing, and business ownership.