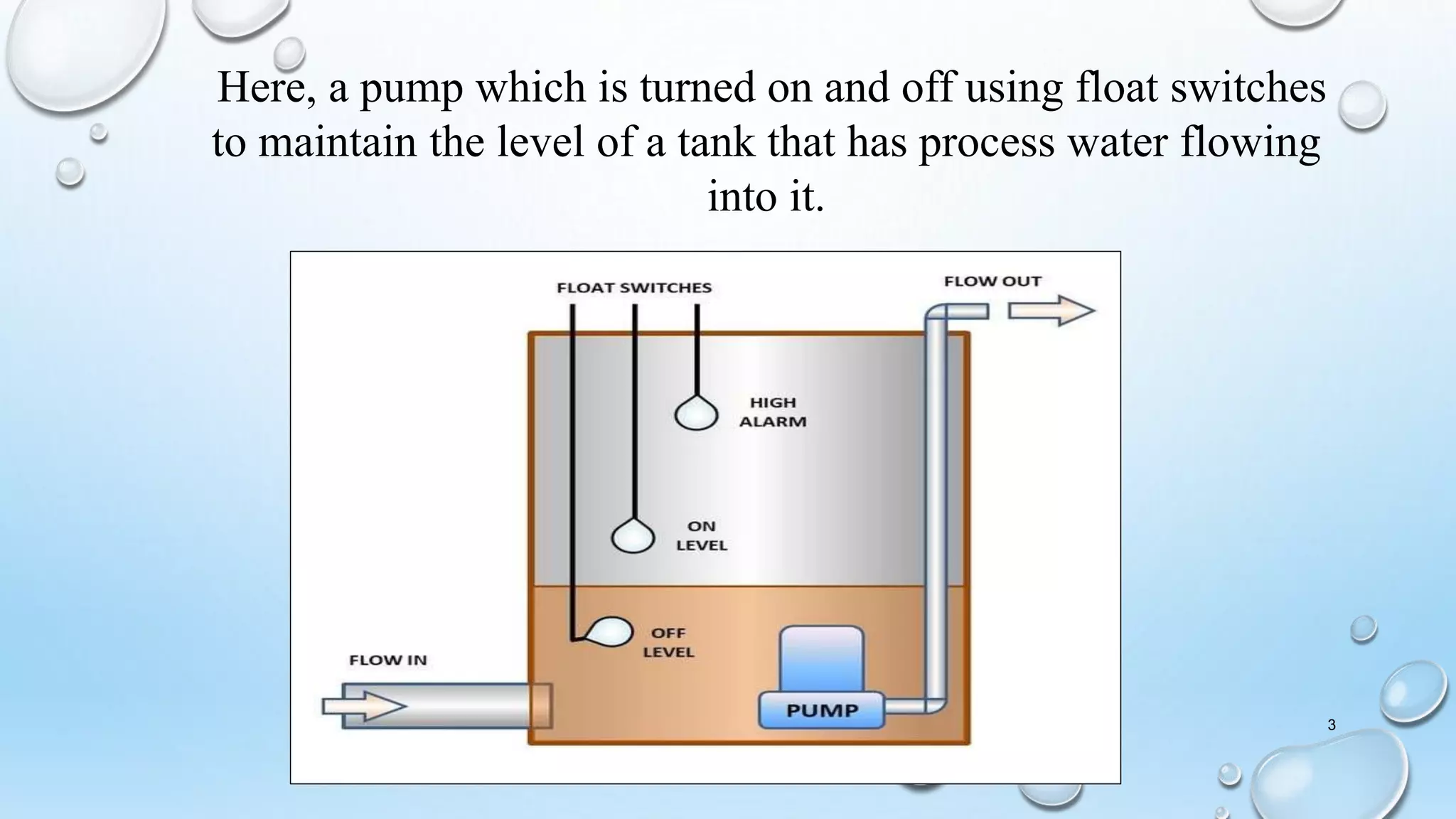

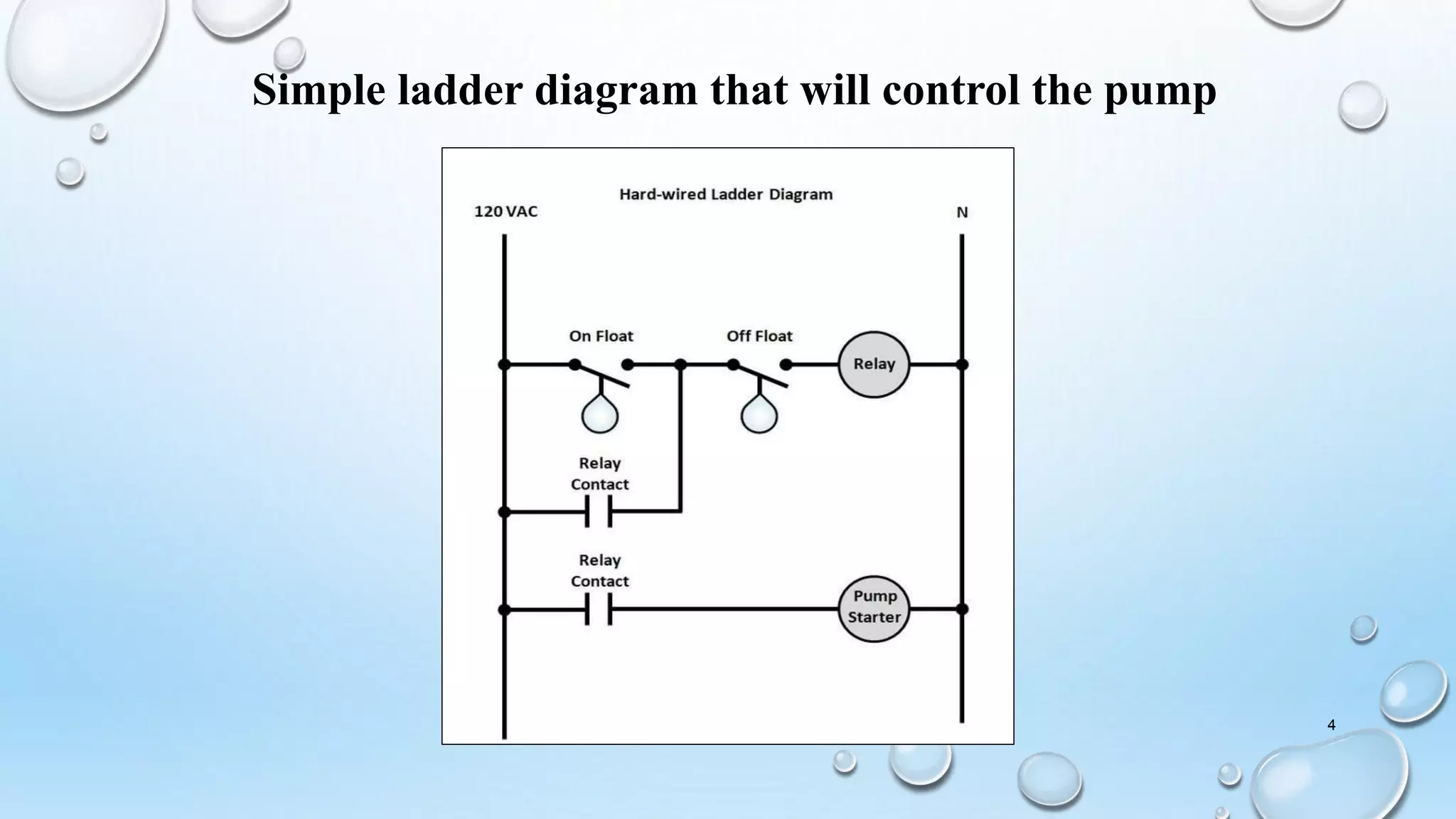

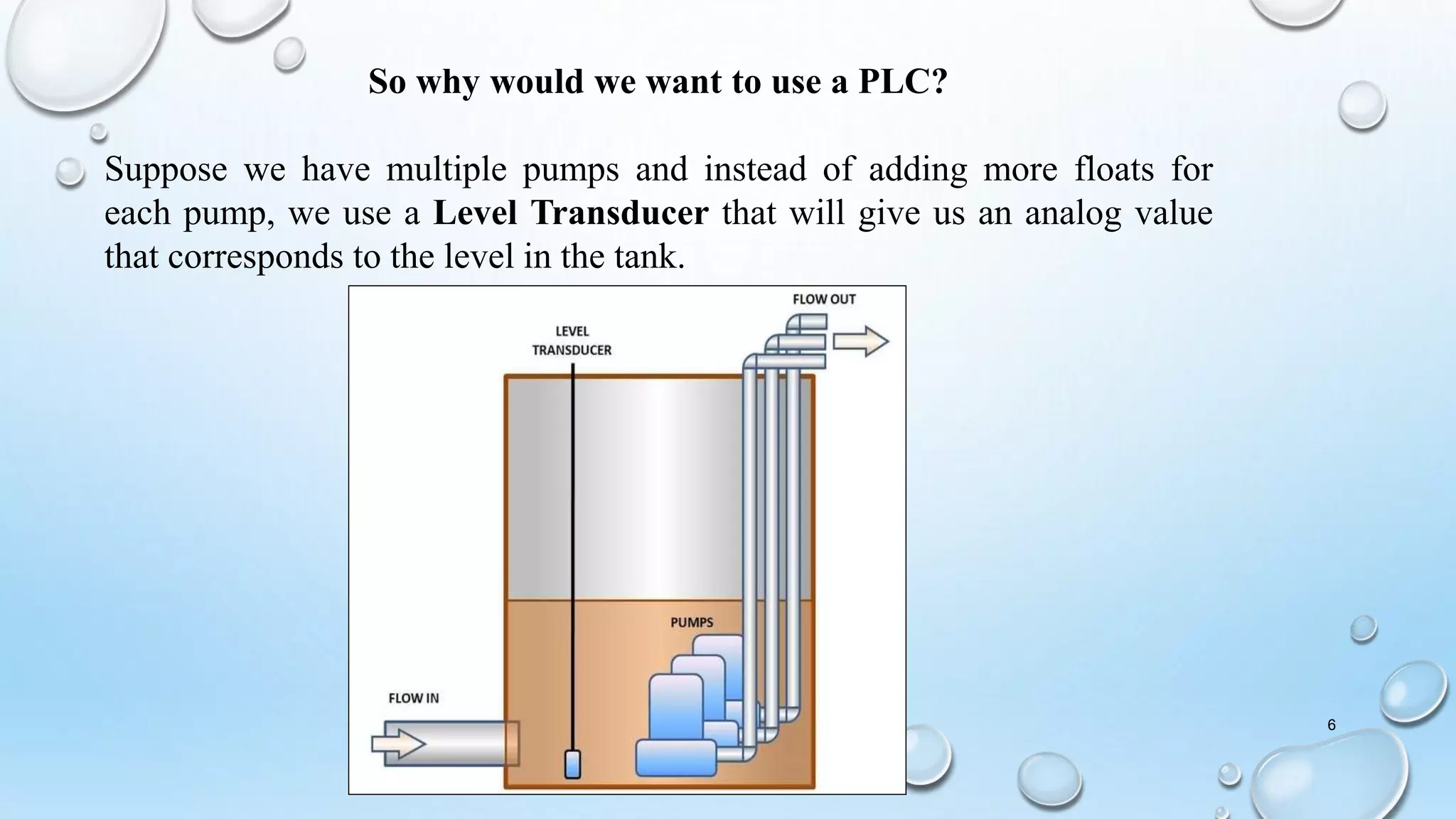

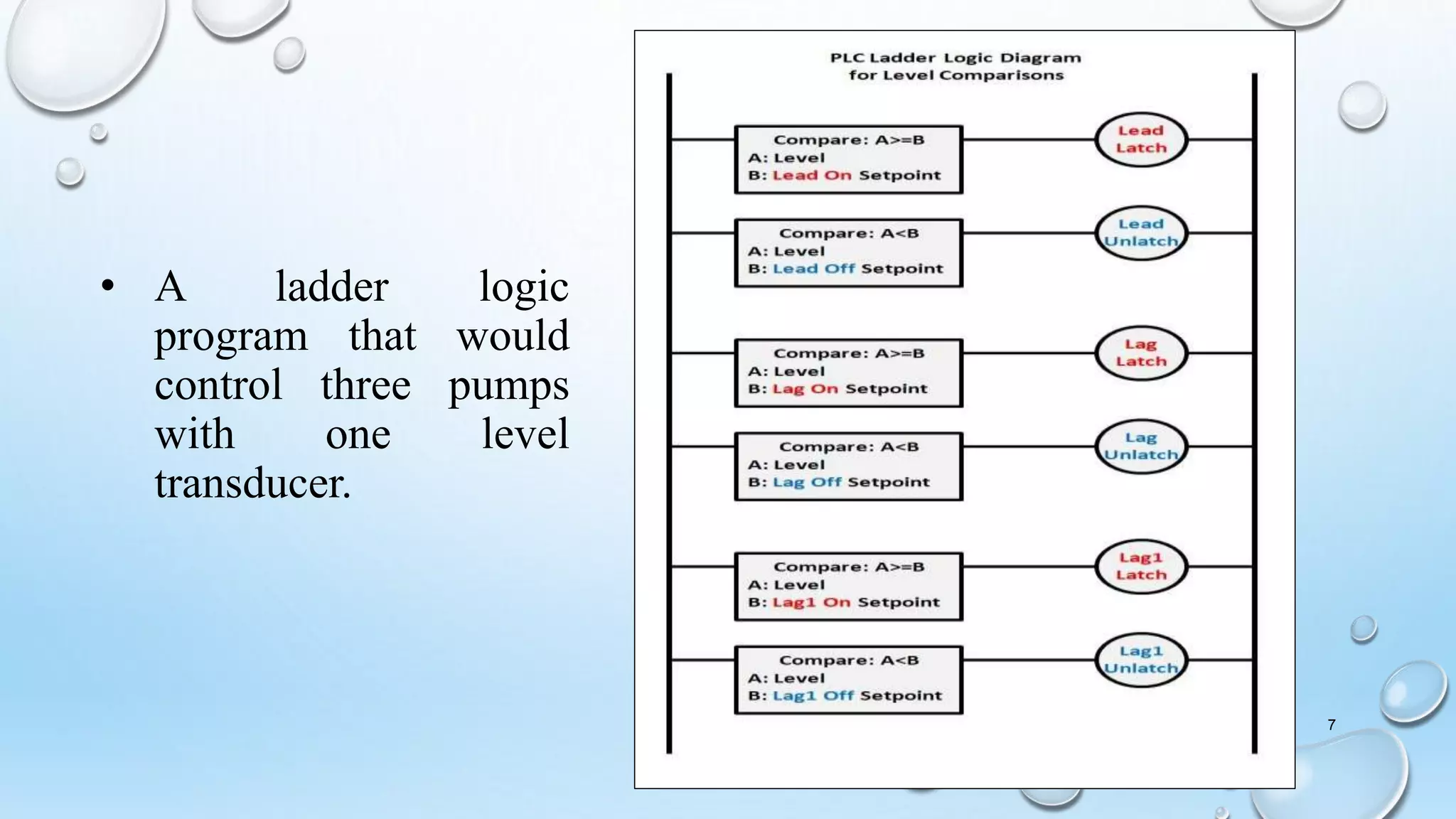

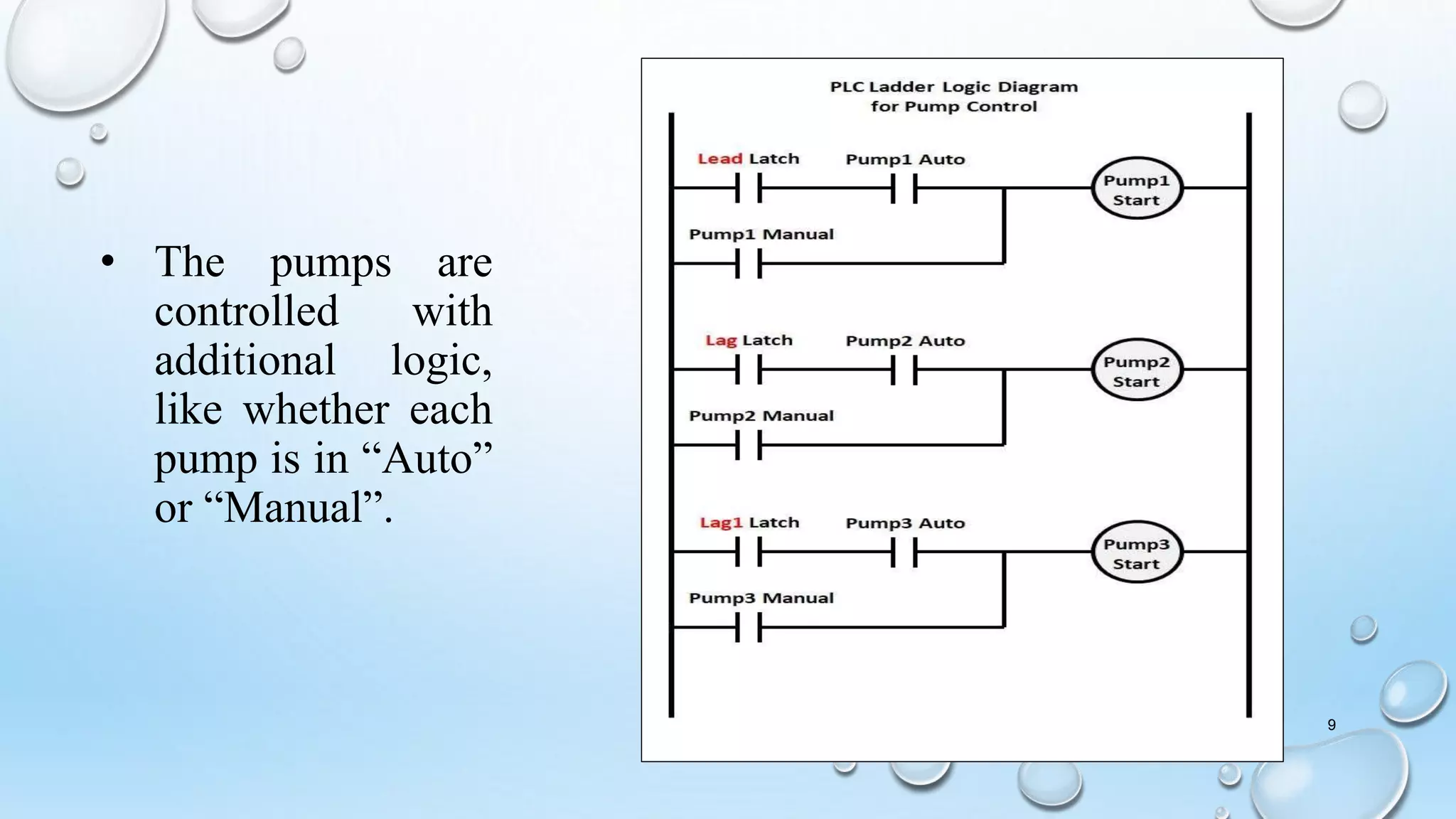

This document describes using a programmable logic controller (PLC) to control a water pump based on the water level in a tank. It begins by explaining how a relay circuit can be used to turn the pump on and off based on float switches. It then discusses how a PLC provides advantages over a relay circuit by allowing more flexible control of multiple pumps using a single level transducer input. The PLC program uses ladder logic to compare the analog water level signal to setpoints to control lead, lag, and lag1 pumps. Overall, the PLC provides easier programming and expansion compared to a relay circuit to control the water pump system.