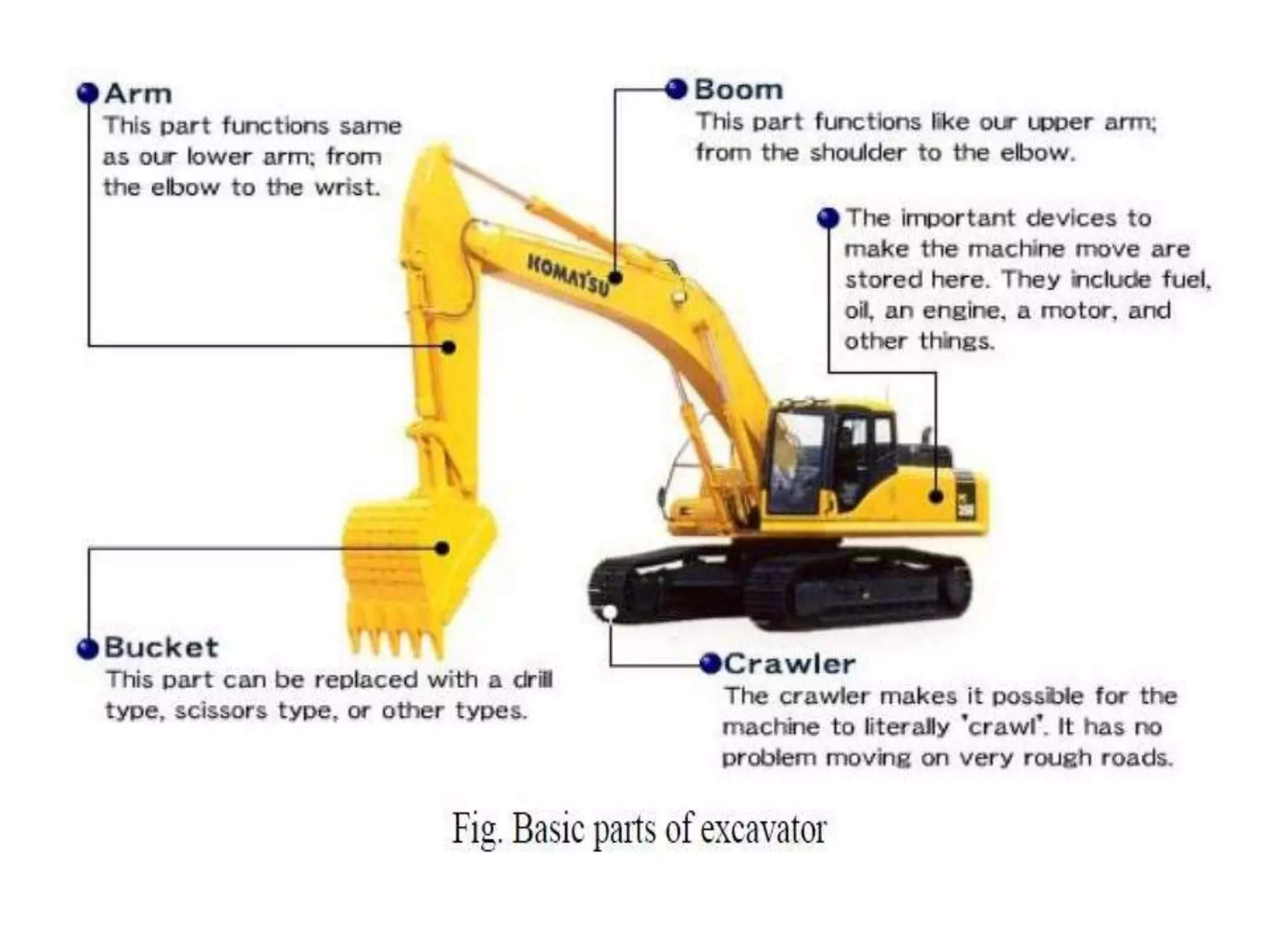

This document outlines the essential steps of construction project planning, emphasizing the importance of creating a comprehensive project initiation document, setting S.M.A.R.T. and C.L.E.A.R. goals, executing the plan, tracking performance, and evaluating the project outcomes. It also discusses the role of mechanization and construction equipment, particularly excavators, in enhancing efficiency and safety on job sites. The document highlights the need for careful planning and team collaboration to ensure project success and maintain high-quality standards.