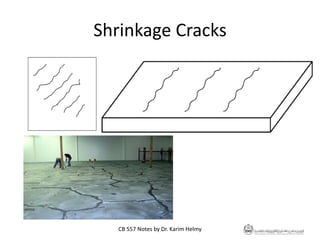

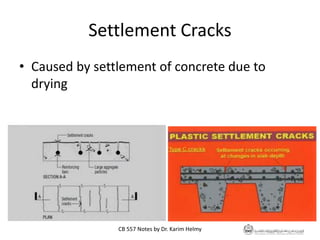

The document discusses various types of concrete defects including fresh concrete defects caused by shrinkage cracks, settlement cracks, and movement of formwork. It also discusses defects from design and detailing errors, construction errors, temperature effects, chemical effects, corrosion of reinforcement steel, and overloading. Some key points are that shrinkage cracks are caused by evaporation of mix water, detailing errors can result in insufficient reinforcement spacing, and overloading can cause cracking and failure of slabs, beams and columns beyond their design capacity.