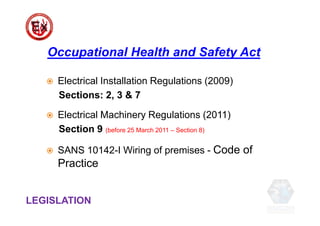

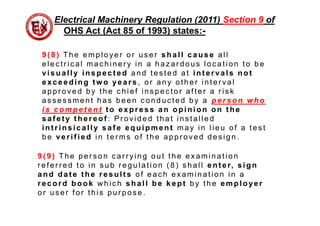

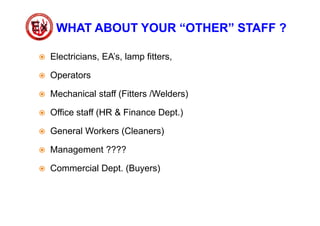

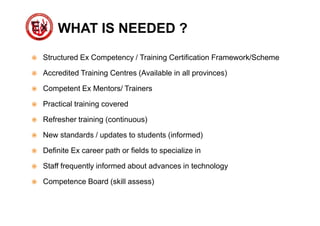

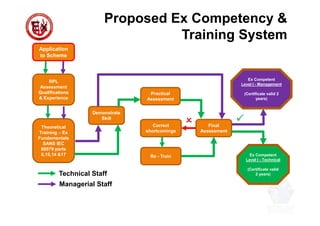

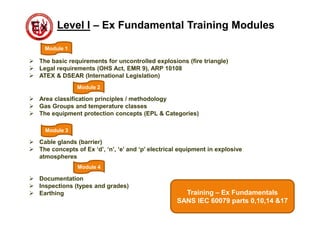

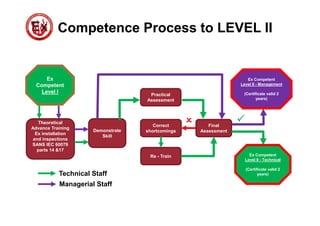

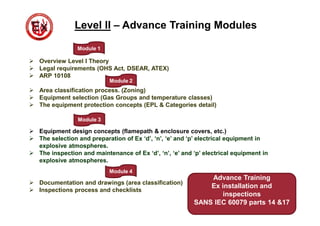

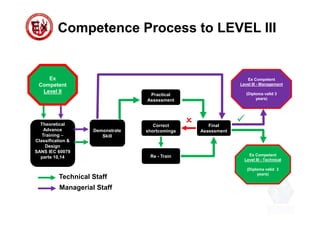

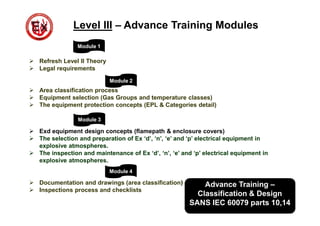

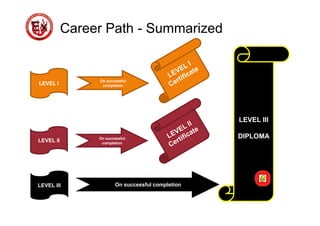

This document discusses occupational health and safety requirements for working with electrical equipment in hazardous locations. It outlines the legal responsibilities under the Occupational Health and Safety Act of 1993, including requirements for inspections, training, and certifications. The document proposes a competency and training framework with multiple levels to ensure workers have the proper qualifications and experience before working with electrical equipment in explosive atmospheres. It emphasizes the importance of both theoretical training and practical experience, as well as continuing education, for maintaining safety.