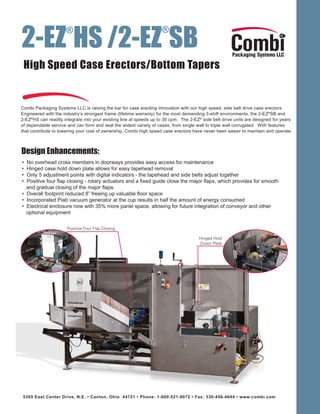

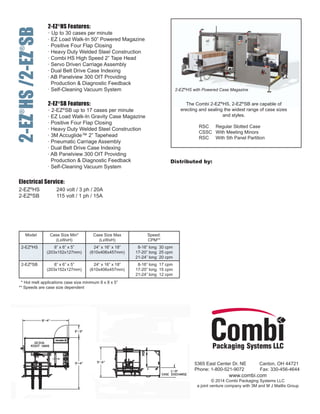

Combi Packaging Systems introduces their high-speed case erectors, the 2-EZ®HS and 2-EZ®SB. These machines can erect and seal cases at speeds up to 30 cases per minute. They are designed for reliability in demanding production environments. The case erectors can accommodate a wide variety of case sizes and styles. They feature innovations like reduced maintenance needs and energy efficiency.