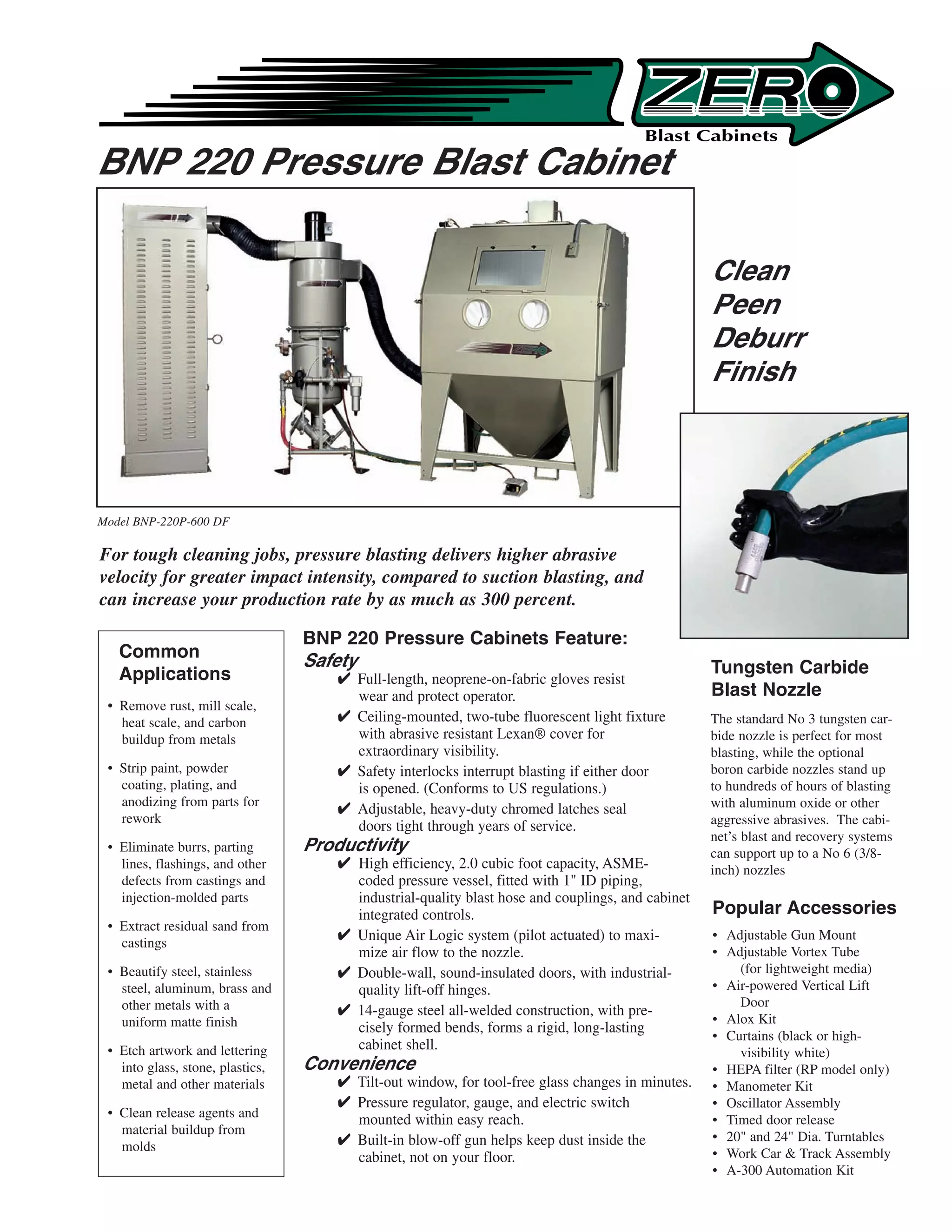

This document summarizes the specifications and features of the BNP 220 Pressure Blast Cabinet. The cabinet uses pressurized air and abrasives to clean, peel, and deburr metal parts, increasing production rates up to 300%. Key features include safety gloves, lighting, interlocks, and adjustable latches. It has a 2.0 cubic foot blast chamber and uses tungsten carbide nozzles. Accessories include gun mounts, lifts, and dust collection options.