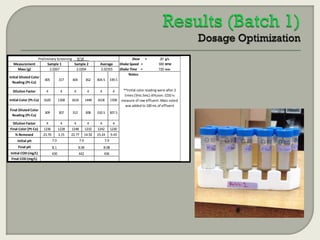

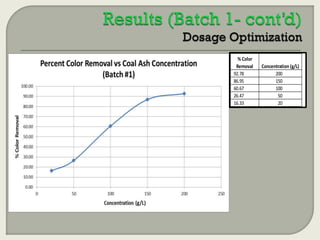

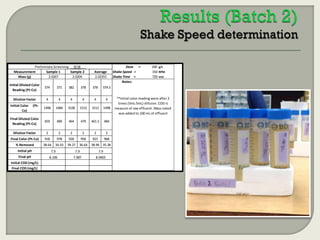

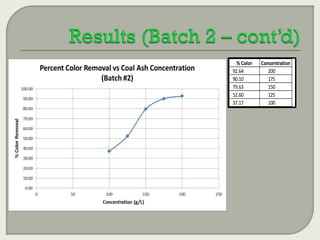

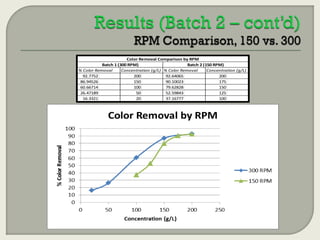

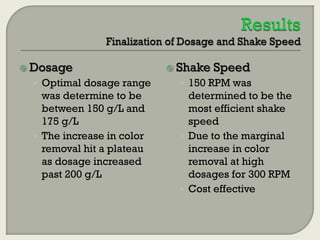

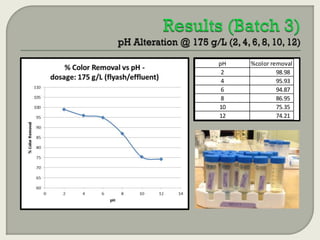

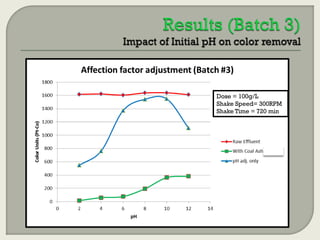

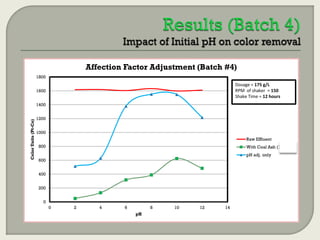

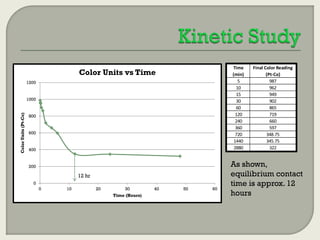

This document summarizes a student research project investigating the use of coal fly ash as an adsorbent for removing color from pulp mill effluent. The research team analyzed how factors like ash dosage, shake speed, contact time, and pH affected color removal efficiency. Equilibrium was reached within 12 hours, and dosage optimization found 175g/L of ash most effective. Adsorption models showed the process was more complicated than simple physical adsorption. The team received a research grant and plans to present findings at conferences. Further studies include analyzing COD levels and running continuous column tests.

![Process:

Relates the adsorption of

mono-layer molecules onto a

solid surface area to

concentration of

adsorbate

Langmuir Isotherm

Equation is:

[non-linear]

[Linear]

*note: linear Langmuir

equation is in y=mx+b

form

1/Ce

0.00073

0.001071

0.001718

0.002677

0.004878

0.005563

0.005814

Expected Asorption Rate (q)

19.72386588

mg/g

b

-2.729

Langmuir Isotherm Model

0.12

1/adsorption capacity (1/qe)

1/qe

0.097491

0.019339

0.014456

0.013972

0.014126

0.015801

0.017695

0.1

y = -7.2275x + 0.0507

R² = 0.2583

0.08

0.06

0.04

0.02

0

0

0.001

0.002

0.003

0.004

0.005

0.006

Concentration of Color at Equilibrium (Ce)

0.007](https://image.slidesharecdn.com/finalpresentation2013-140306141722-phpapp01/85/Color-Removal-25-320.jpg)

![Process:

o

Relation of concentration

of a solute on the surface

of the media to the

concentration of solute left

in liquid

Freundlich

Isotherm Equation

is:

[non-linear]

[Linear]

*note: linear Freundlich

equation is in y=mx+b

form, but on log scale

Log Ce

3.136403

2.970347

2.764923

2.572291

2.311754

2.254669

2.235528

K

3.153

1/n

-0.5617

Freundlich Isotherm Model

2.000

1.800

1.600

1.400

log (qe)

log (qe )

1.011

1.714

1.840

1.855

1.850

1.801

1.752

1.200

y = -0.5617x + 3.153

R² = 0.4494

1.000

0.800

0.600

0.400

0.200

0.000

1.5

2

2.5

Log Ce

3

3.5](https://image.slidesharecdn.com/finalpresentation2013-140306141722-phpapp01/85/Color-Removal-26-320.jpg)