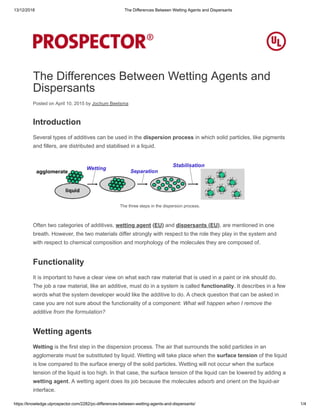

Wetting agents and dispersants are both additives used in the dispersion process but have different functions. Wetting agents lower the surface tension of liquids to allow solid particles to be wet, which is the first step of dispersion. Dispersants adsorb to particle surfaces and provide repulsion between particles to prevent them from flocculating after separation. Wetting agents work by adsorbing to liquid-air interfaces while dispersants adsorb to solid-liquid interfaces and can provide electrostatic or steric stabilization between particles. Both are important interface additives but have distinct roles in the dispersion process.