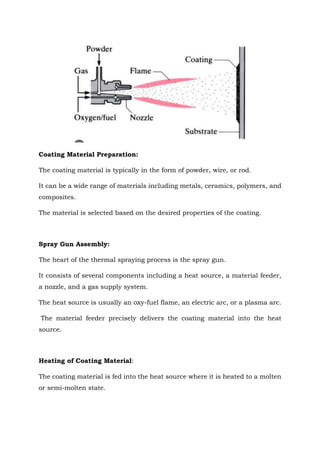

Thermal spraying is a surface engineering technique that improves or restores the surface of materials. It involves heating coating material like metal, ceramic, polymer powders and spraying them onto a substrate. There are different thermal spraying processes like plasma spraying, detonation spraying, flame spraying and HVOF. The coating material is pre-heated and accelerated towards the substrate where it forms a layer through solidification. Multiple layers are deposited through repetition to achieve the desired coating thickness. The coated surface may then undergo finishing and post-treatment processes. Thermal spraying provides a versatile and cost-effective solution for applying wear and corrosion resistant coatings in various industries.