Embed presentation

Download to read offline

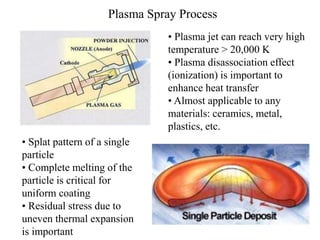

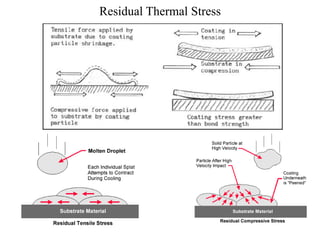

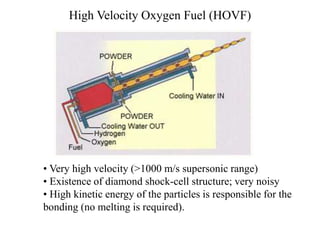

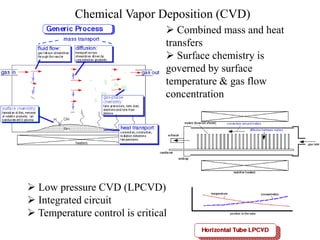

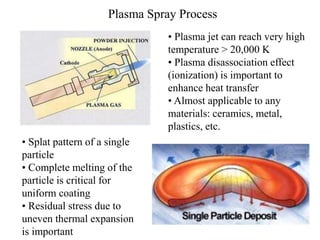

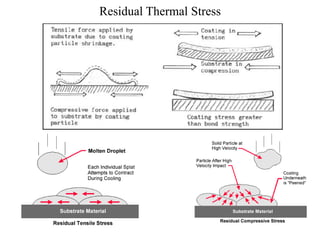

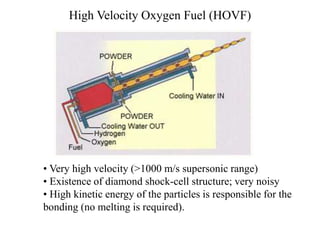

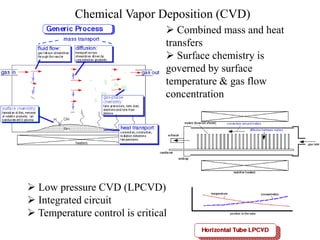

The document discusses several coating processes including plasma spray, which uses a plasma jet over 20,000 K to melt and propel particles onto a substrate, complete melting is important for uniformity and residual stress can occur from uneven thermal expansion. It also discusses high velocity oxygen fuel coating which uses supersonic particle velocities over 1000 m/s for bonding through kinetic energy without melting, and produces a noisy diamond shock cell structure, and chemical vapor deposition such as low pressure CVD for integrated circuits where temperature control is critical and surface chemistry depends on temperature and gas concentration.