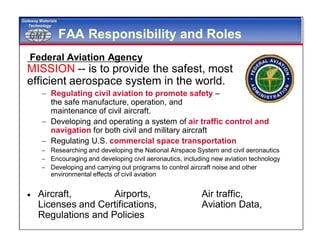

The document discusses the challenges of certifying ceramic matrix composite (CMC) components for use in commercial aircraft with the Federal Aviation Administration (FAA). It provides an overview of the FAA certification process and requirements, noting that certification is more difficult for CMCs than traditional polymer matrix composites (PMCs) due to differences in material properties. Key certification challenges for CMCs include demonstrating they meet stringent FAA regulations regarding material strength, durability, damage tolerance, and that they will maintain airworthiness over the service life of an aircraft.

![GMTGMT

Gateway Materials

Technology

Polymer Matrix Composites in the FAA Process

FAA Policy Statements for Composites

Static Strength Substantiation of Composite Airplane Structure

[PS-ACE100-2001-006, December 2001]

Final Policy for Flammability Testing per 14 CFR Part 23, Sections

23.853, 23.855 and 23.1359 [PS-ACE100-2001-002, January 2002]

Material Qualification and Equivalency for Polymer Matrix Composite

Material Systems[PS-ACE100-2002-006, September 2003]

Bonded Joints and Structures - Technical Issues and Certification

Considerations [PS-ACE100-2005-10038, September 2005]](https://image.slidesharecdn.com/a63d554a-7632-445c-925d-5c9724c2aad4-150328110458-conversion-gate01/85/CMC-FAA-Certification-24-320.jpg)

![GMTGMT

Gateway Materials

Technology

Polymer Matrix Composites in the FAA Process

FAA Technical Reports

“Fiber Composite Analysis And Design Volume II Structures”

[DOT-FAA-CT-88-18, Nov. 1979)

"Certification Testing Methodology for Composite Structures, Volumes I

and II" [DOT/FAA/CT-86/39, October 1986]

“Handbook: Manufacturing Advanced Composite Components for

Airframes” [DOT/FAA/AR- 96/75, April 1997]

”Fiber Composite Analysis and Design, Volume I Composite Materials

and Laminates” [DOT/FAA/CT-85/6 , Oct 1997]

"Advanced Certification Methodology for Composite Structures"

[DOT/FAA/AR-96/111, April 1997]](https://image.slidesharecdn.com/a63d554a-7632-445c-925d-5c9724c2aad4-150328110458-conversion-gate01/85/CMC-FAA-Certification-26-320.jpg)

![GMTGMT

Gateway Materials

Technology

Polymer Matrix Composites in the FAA Process

FAA Technical Reports

“Guidelines and Recommended Criteria for the Development of a Material

Specification for Carbon Fiber/Epoxy Unidirectional Prepregs"

[DOT/FAA/AR-02/109, March 2003]

“Guidelines for the Development of Process Specifications, Instructions, and

Controls for the Fabrication of Fiber-Reinforced Polymer Composites"

[DOT/FAA/AR-02/110, March 2003]

"Guidelines for Analysis, Testing, and Nondestructive Inspection of Impact-

Damaged Composite Sandwich Structures"

[DOT/FAA/AR-02/121, March 2003]

“Material Qualification and Equivalency for Polymer Matrix Composite Material

Systems“ [DOT/FAA/AR-03/19, September 2003]

"Assessment of Industry Practices for Aircraft Bonded Joints and Structures"

[DOT/FAA/AR-05/13, July 2005]

Aviation Maintenance Technician (AMT) Airframe Handbook Volume 2 (FAA-

H-8083-31) , Chapter 7 Advanced Composites](https://image.slidesharecdn.com/a63d554a-7632-445c-925d-5c9724c2aad4-150328110458-conversion-gate01/85/CMC-FAA-Certification-27-320.jpg)