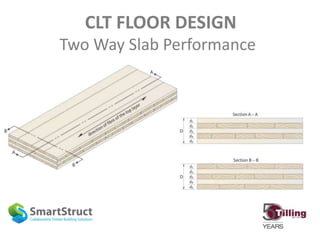

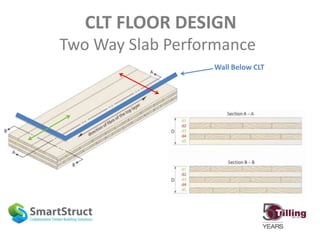

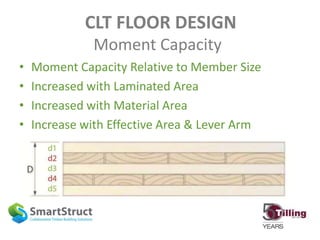

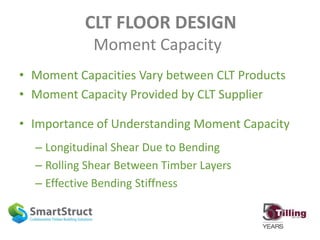

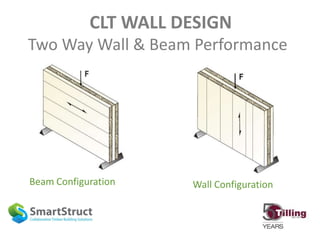

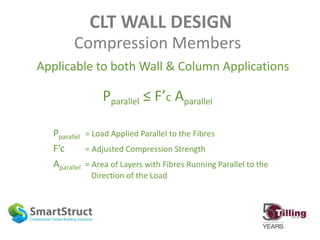

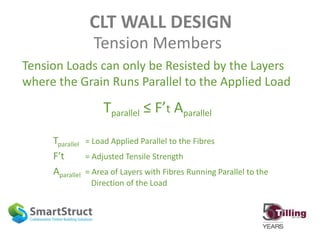

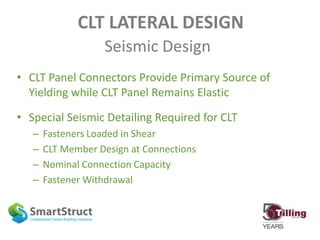

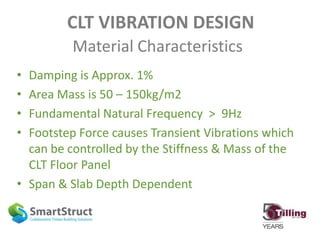

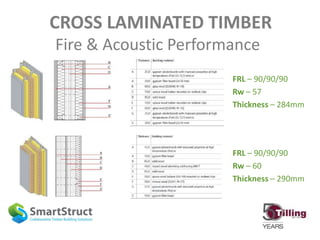

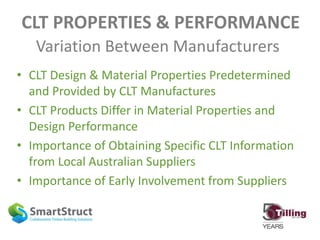

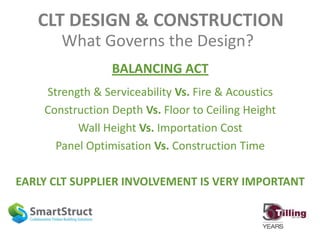

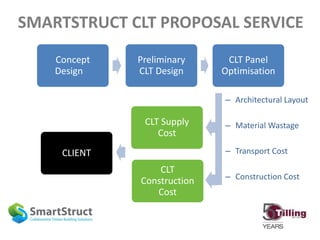

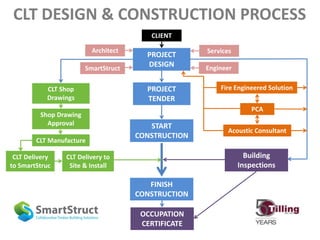

The document discusses design considerations for cross-laminated timber (CLT) buildings. It covers optimal CLT designs and applications, material properties, design resources, suitable projects, finishes, floor, wall and lateral designs. It also addresses vibration, fire, acoustic performance, connections, termite control, variations between manufacturers, design software, balancing strength with other factors, importation, and the CLT design and construction process when working with a supplier like SmartStruct.