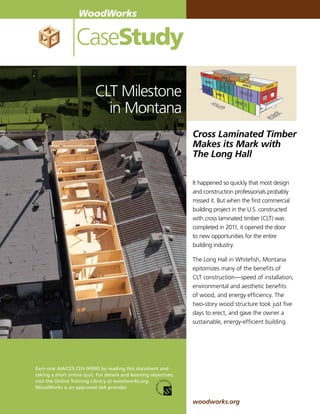

The Long Hall in Whitefish, Montana, is the first commercial building in the U.S. constructed with cross laminated timber (CLT), completed in just five days, showcasing the benefits of speed, sustainability, and aesthetics. Designed to replace an old structure, it features a mixed-use space and a martial arts studio, with a focus on energy efficiency and cost-effectiveness. CLT's thermal performance, lower carbon footprint, and rapid installation were critical factors that led to its successful adoption in this innovative project.