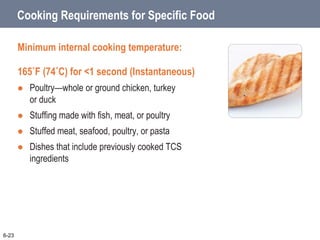

This document provides guidelines for food preparation including preventing cross-contamination, proper thawing, cooking to the correct internal temperatures, cooling food correctly, reheating food safely, and using proper preparation practices for specific foods like eggs and produce. It also covers requirements for partial cooking, consumer advisories, cooling time and temperature abuse, approved food additives, and practices for high-risk populations.