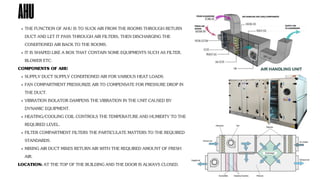

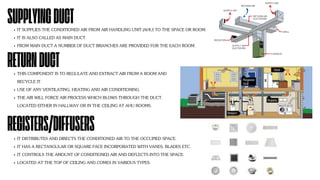

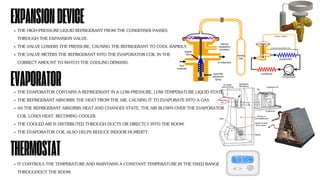

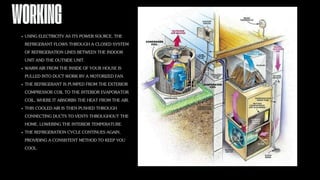

Centralized air conditioning (AC) systems cool air at a single location and distribute it through ducts to various rooms, featuring components like the evaporator, compressor, and thermostat. These systems are efficient for large spaces, providing consistent cooling and improved air quality, but require significant investment for installation and maintenance. They are particularly suitable for large homes, offices, and commercial venues but may be less efficient for smaller buildings.