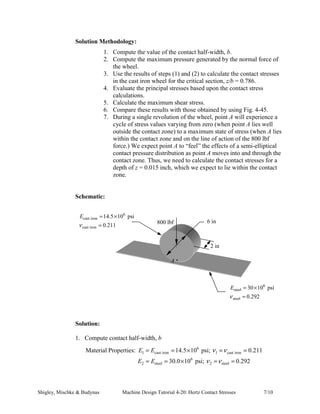

This document discusses Hertz contact stresses, focusing on the characteristics and calculations involved in point and line contact between curved bodies. It presents design cases for sphere-sphere and cylinder-cylinder contacts, detailing how the contact area impacts stress distribution and failure modes, such as flaking or pitting. Furthermore, it includes methodology for calculating critical stress values and shear stresses, as well as practical examples of load applications and stress calculations.