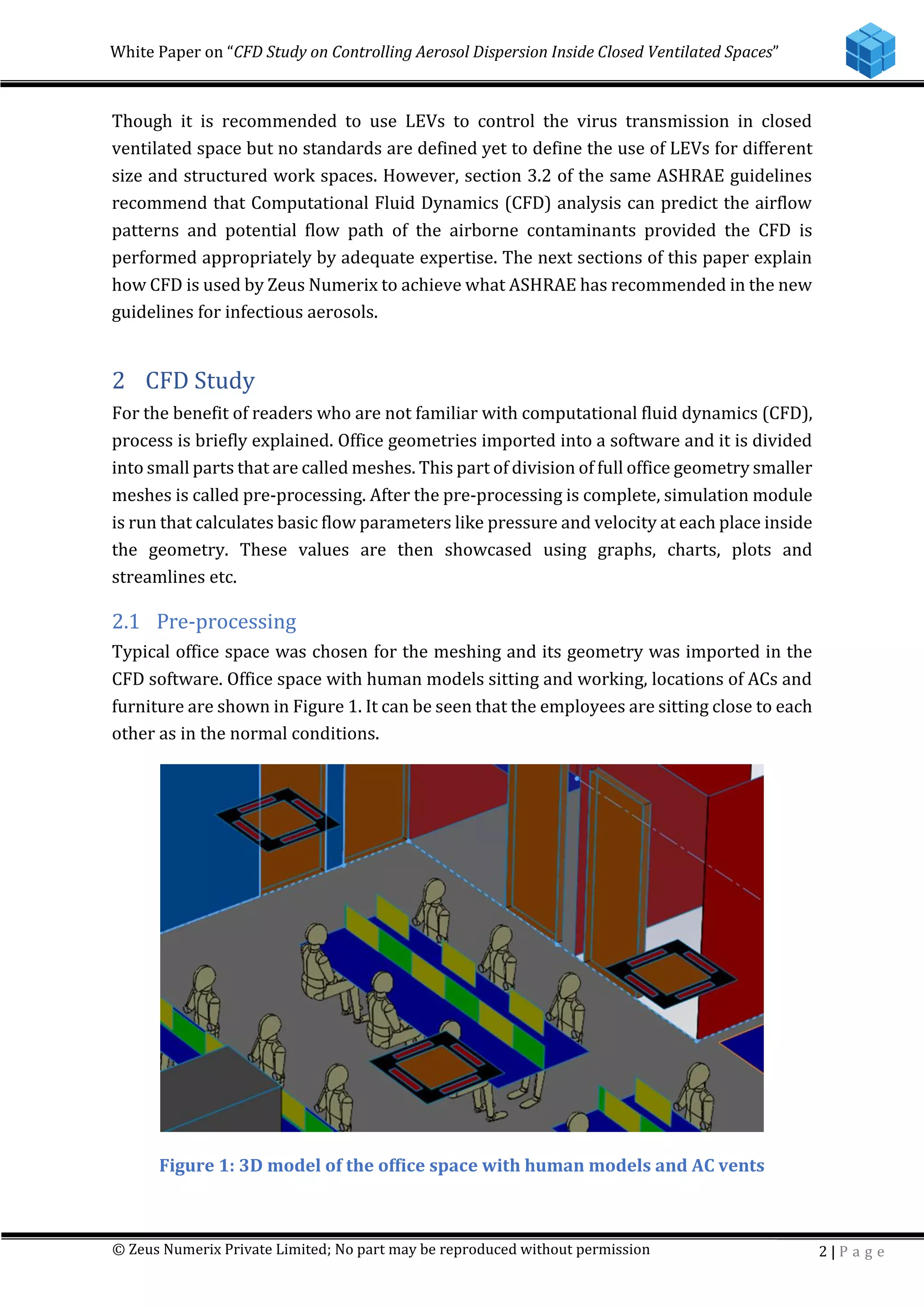

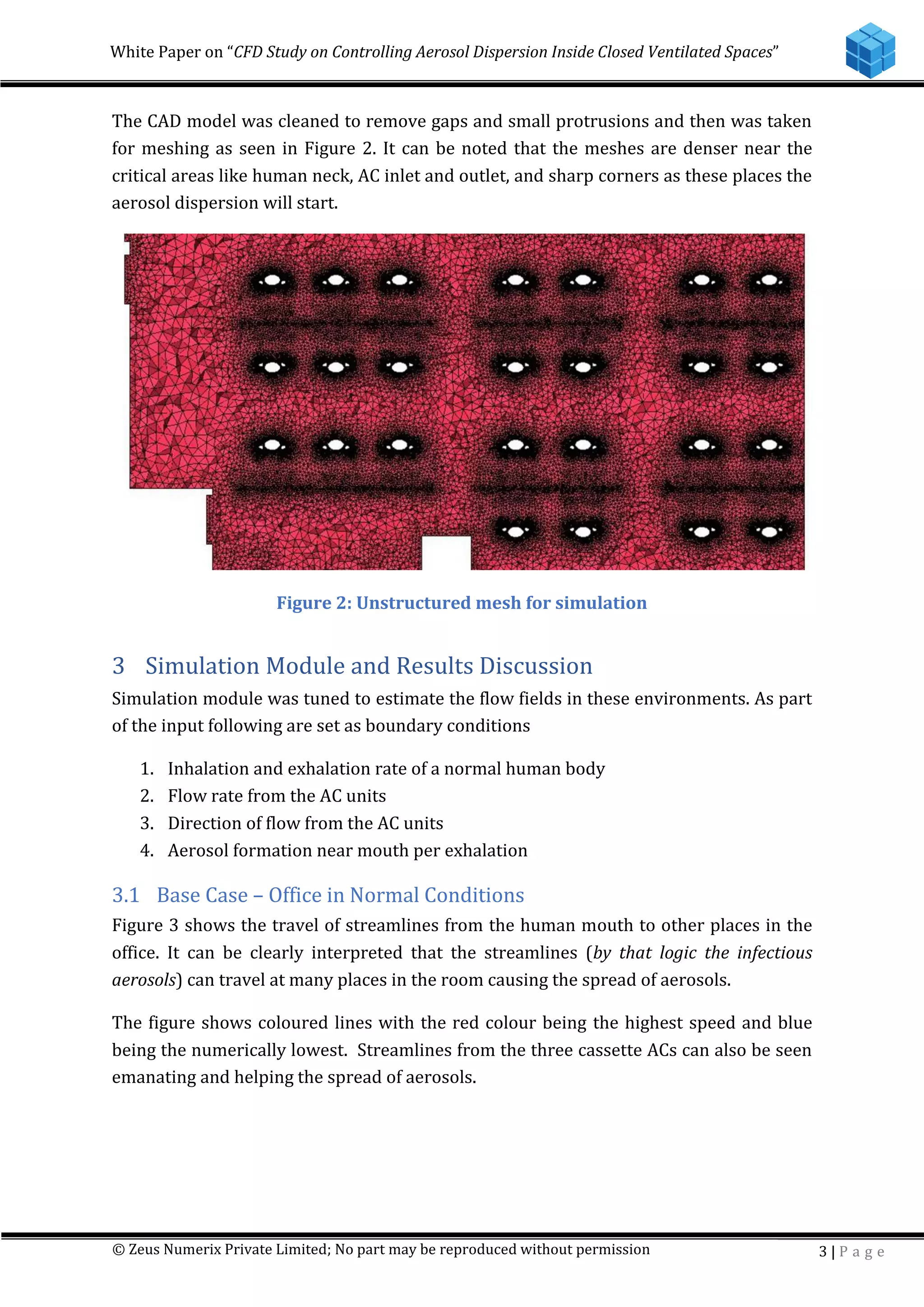

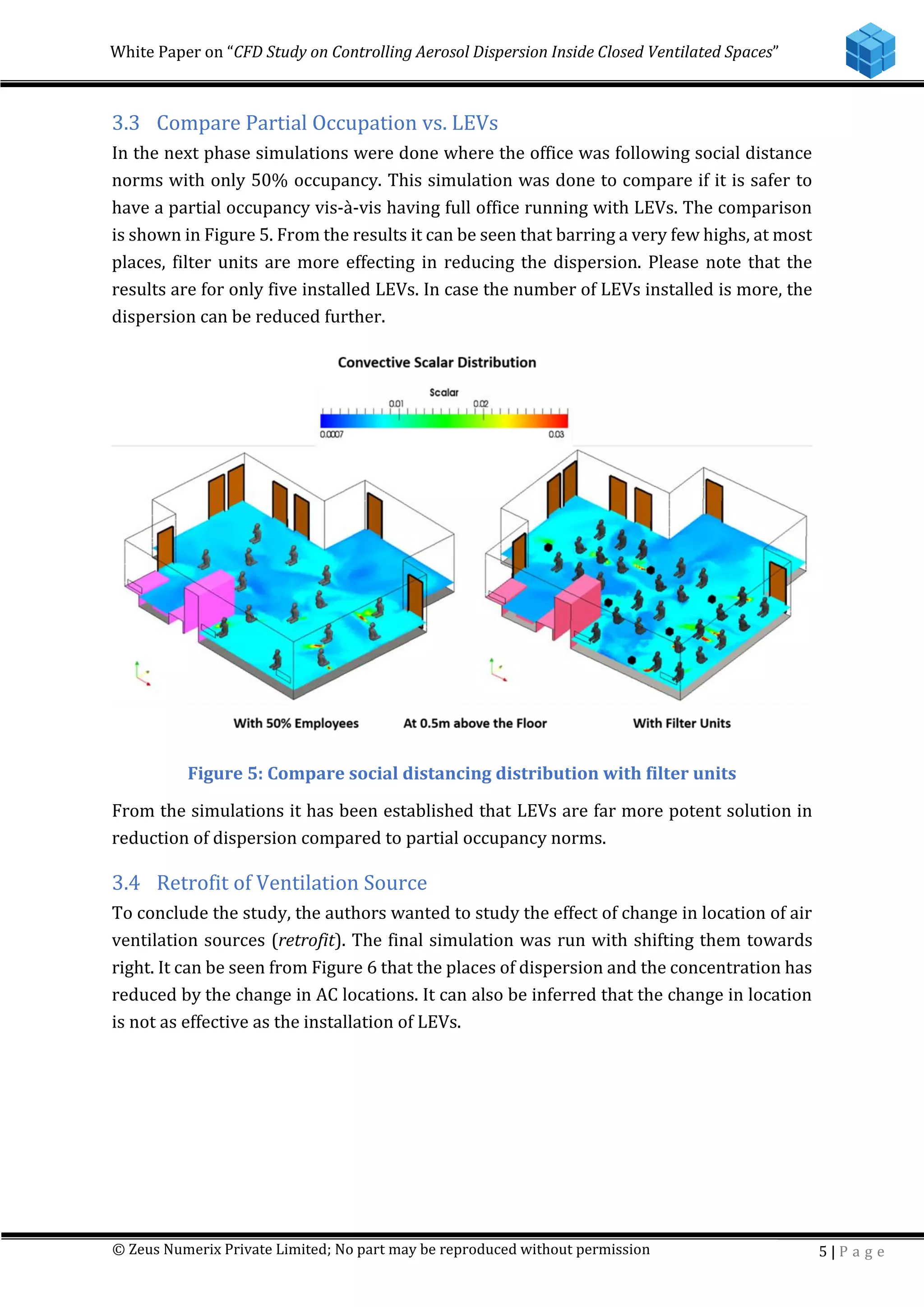

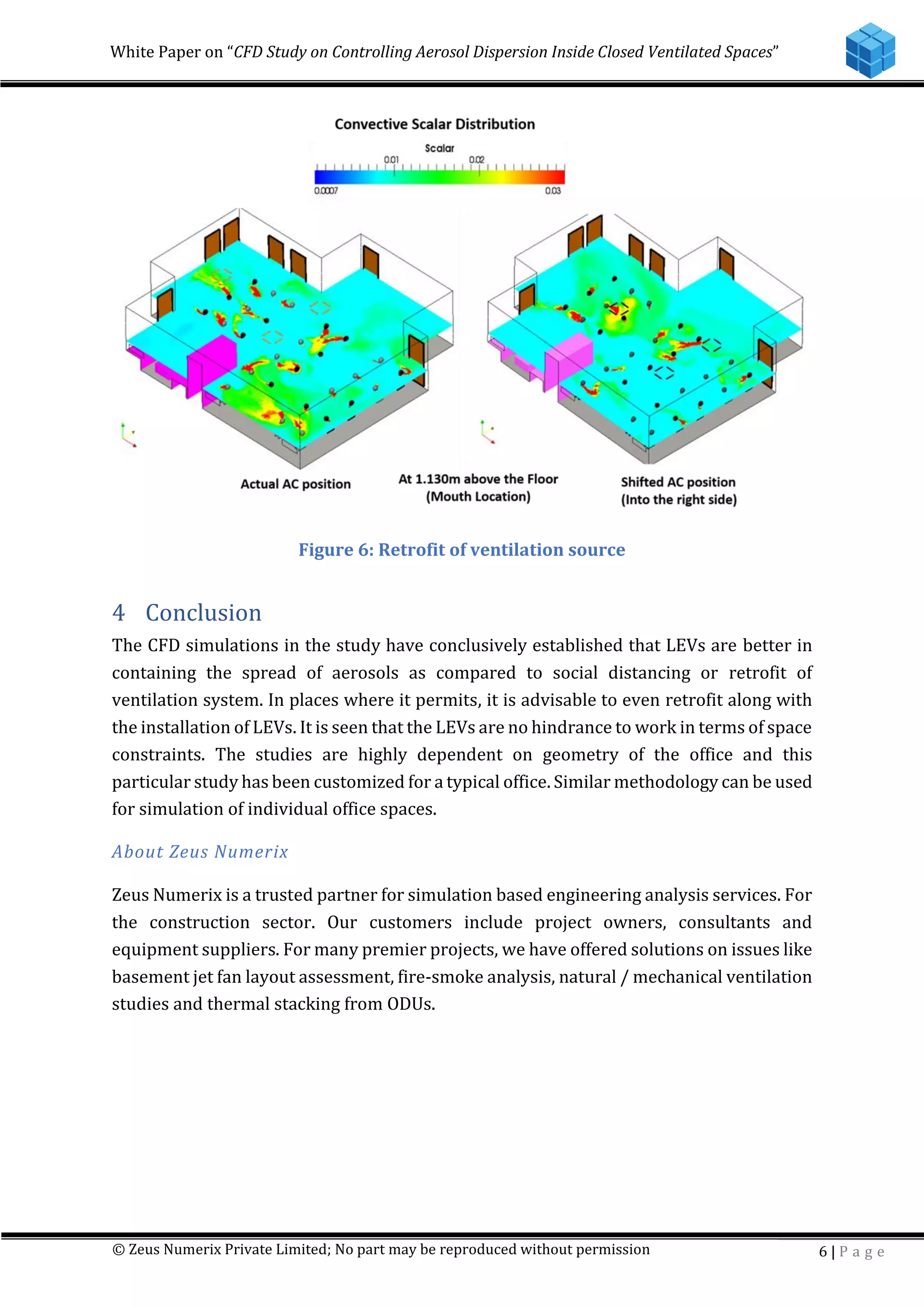

This document presents a CFD study by Zeus Numerix focused on controlling aerosol dispersion in closed ventilated spaces, particularly offices, during the pandemic. It outlines various scenarios including the effectiveness of local exhaust ventilation (LEVs) and air purifiers compared to social distancing measures in reducing aerosol spread. The study concludes that LEVs are more effective in preventing aerosol transmission than simply reducing occupancy or retrofitting ventilation systems.