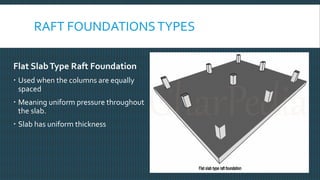

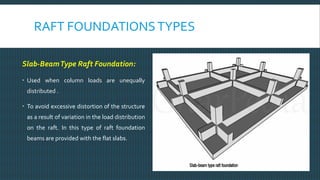

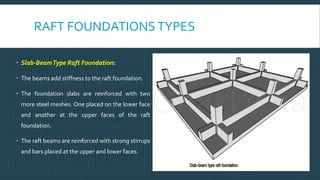

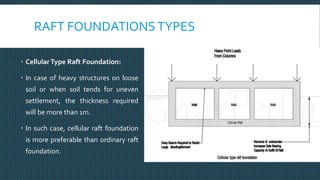

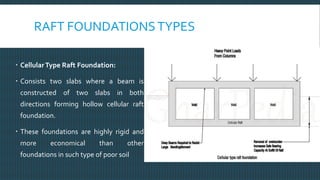

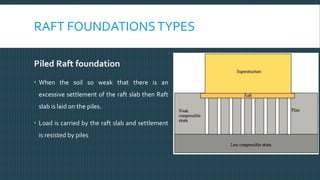

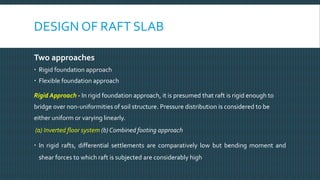

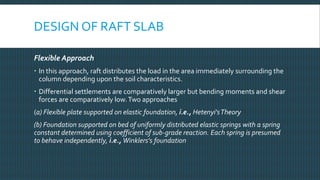

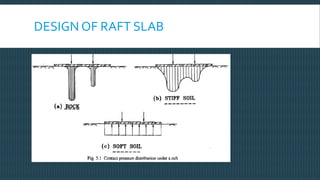

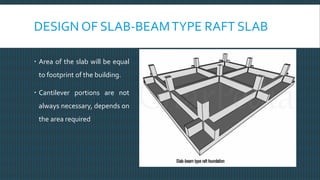

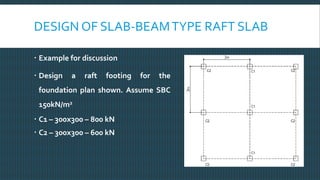

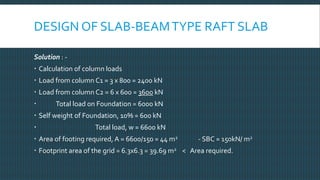

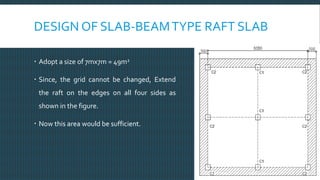

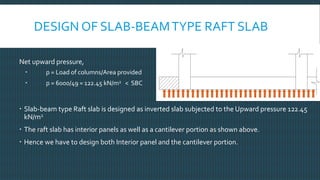

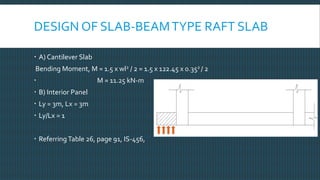

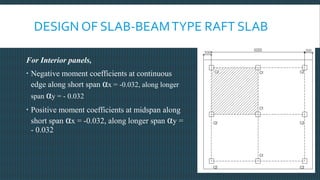

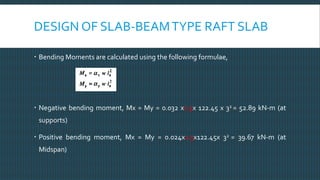

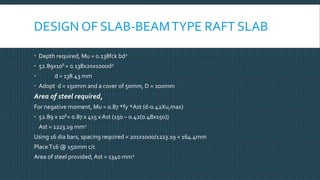

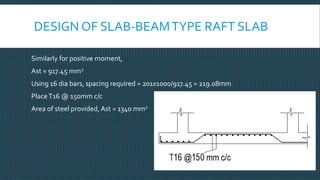

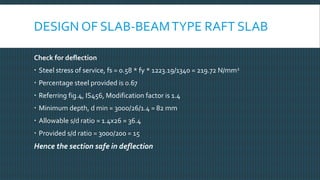

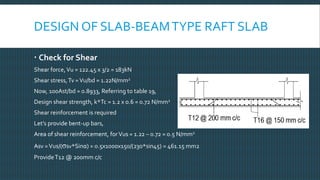

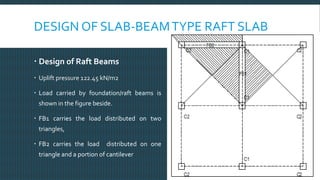

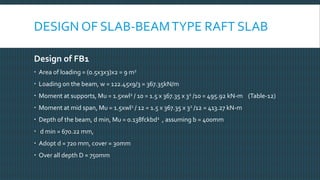

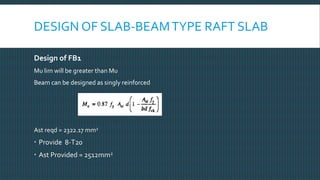

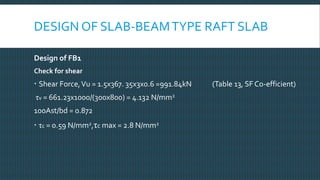

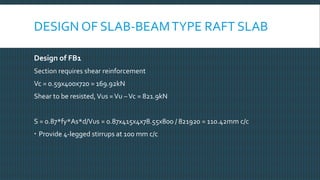

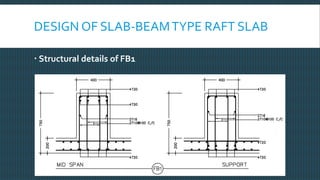

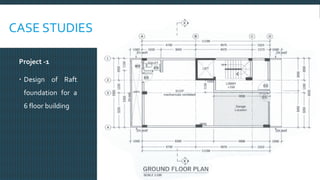

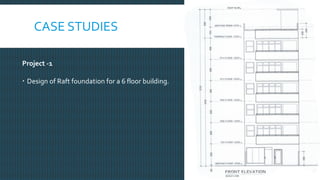

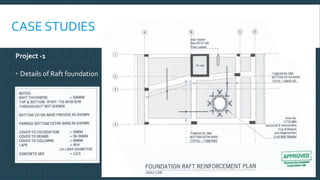

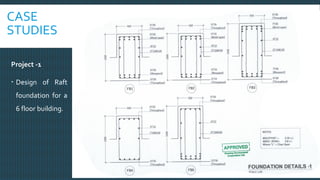

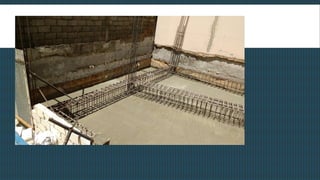

This document discusses raft foundation design concepts for high-rise buildings. A raft foundation is a continuous slab that extends over the entire footprint of a building to transfer its weight uniformly to the soil. It is suitable for buildings with basements. Raft foundations are used when soil bearing capacity is low, loads are high, or differential settlement needs to be minimized. The document describes different types of raft foundations and provides an example design of a slab-beam raft foundation, calculating bending moments, reinforcement requirements, and checking deflection, shear, and cracking.