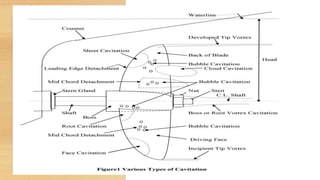

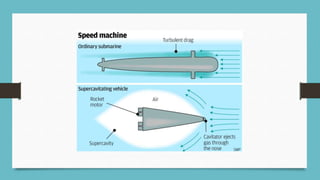

Cavitation is the rapid formation of vapor bubbles in a liquid, particularly affecting ship propellers, reducing efficiency and causing damage due to bubble collapse. Various types of cavitation, like sheet, bubble, and vortex cavitation, lead to performance issues such as erosion, vibration, and noise. To mitigate these effects, measures such as increasing blade area and adjusting pitch are recommended, and cavitation tunnels are utilized for testing propeller performance under controlled conditions.