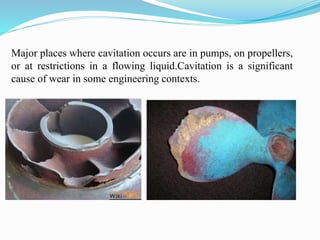

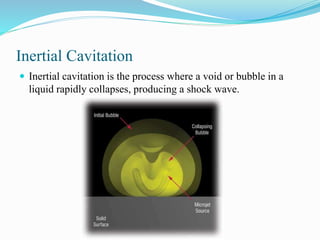

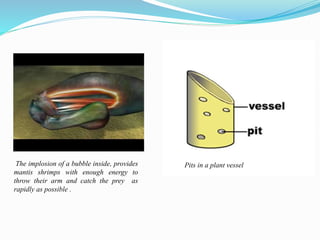

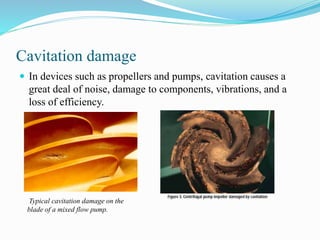

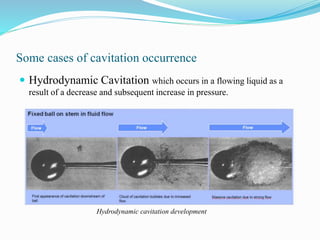

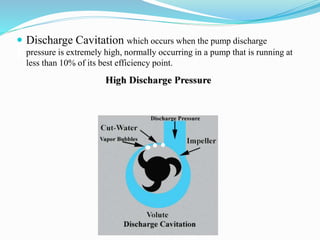

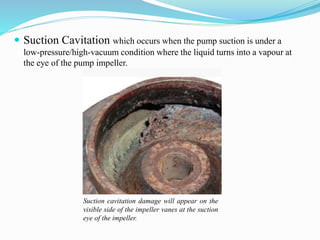

Cavitation occurs when cavities form in liquid due to pressure changes and then rapidly collapse, producing shockwaves. There are two types: inertial cavitation involves rapid bubble collapse producing shockwaves, while non-inertial cavitation involves bubble oscillation due to acoustic energy. Cavitation commonly occurs in pumps, propellers, and where liquids experience pressure changes, and can cause damage through noise, vibrations and material erosion. Solutions involve redesigning systems, changing materials, reducing turbulence, and adding anti-cavitation agents.