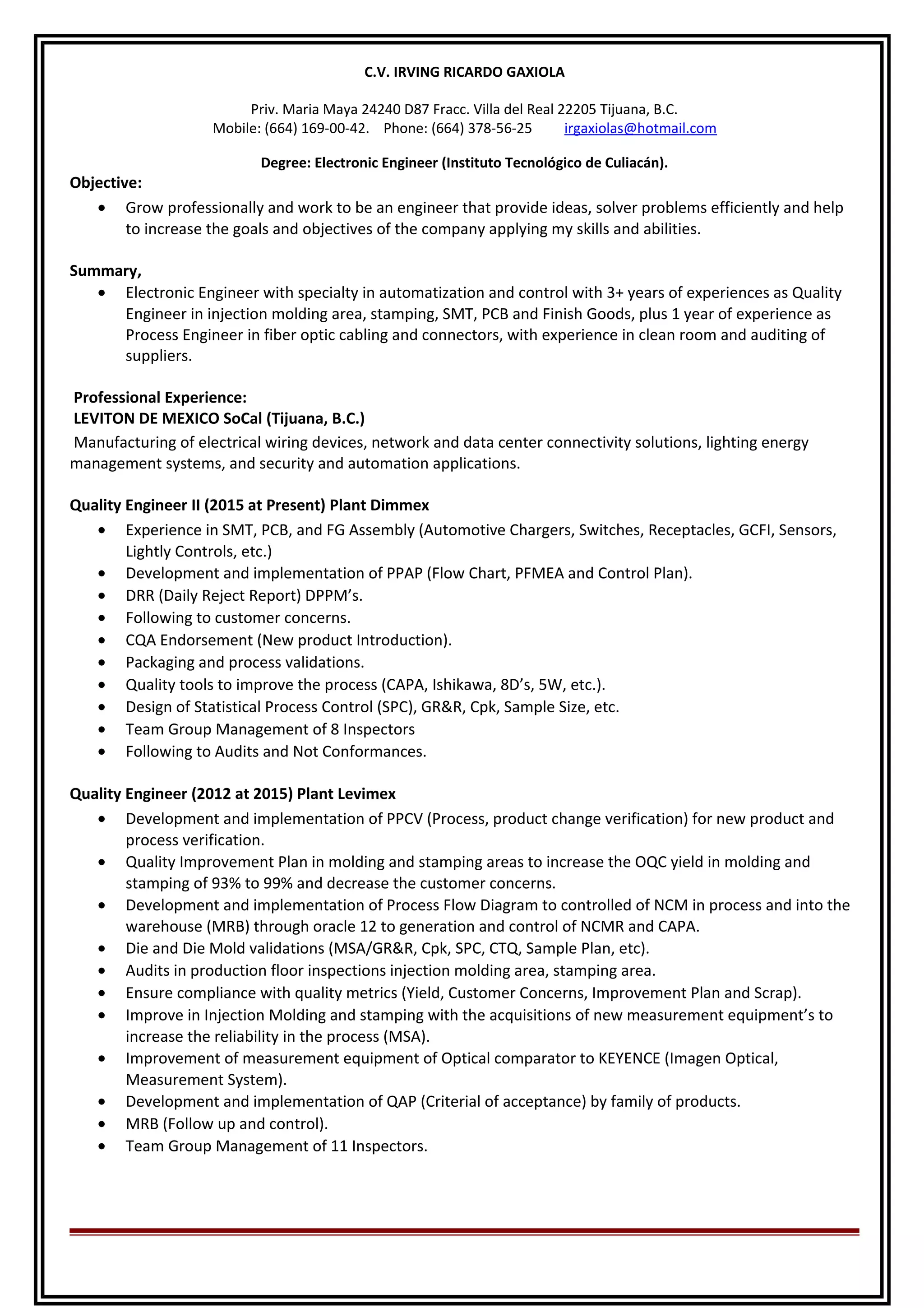

C.V. IRVING RICARDO GAXIOLA is an electronic engineer with over 10 years of experience in quality engineering and process engineering roles. He has worked for LEVITON DE MEXICO and BELDEN de Sonora, focusing on quality control, process improvement, and new product development. His experience includes work in injection molding, stamping, SMT, PCB assembly, and fiber optic cabling. Key accomplishments include improving yield from 93% to 99% and reducing customer concerns through quality plans and measurement system analysis.