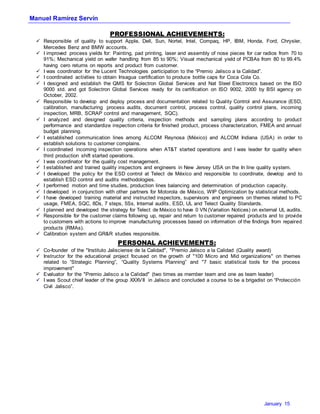

Manuel Ramírez Servín is an industrial engineer from Mexico with over 30 years of experience in quality engineering roles. He has worked for numerous companies in various industries, with a focus on quality control and assurance. Some of his responsibilities have included developing quality management systems, performing audits, training personnel, and improving process yields. He is skilled in various quality control and improvement methods and holds a Level II certification in SQC.