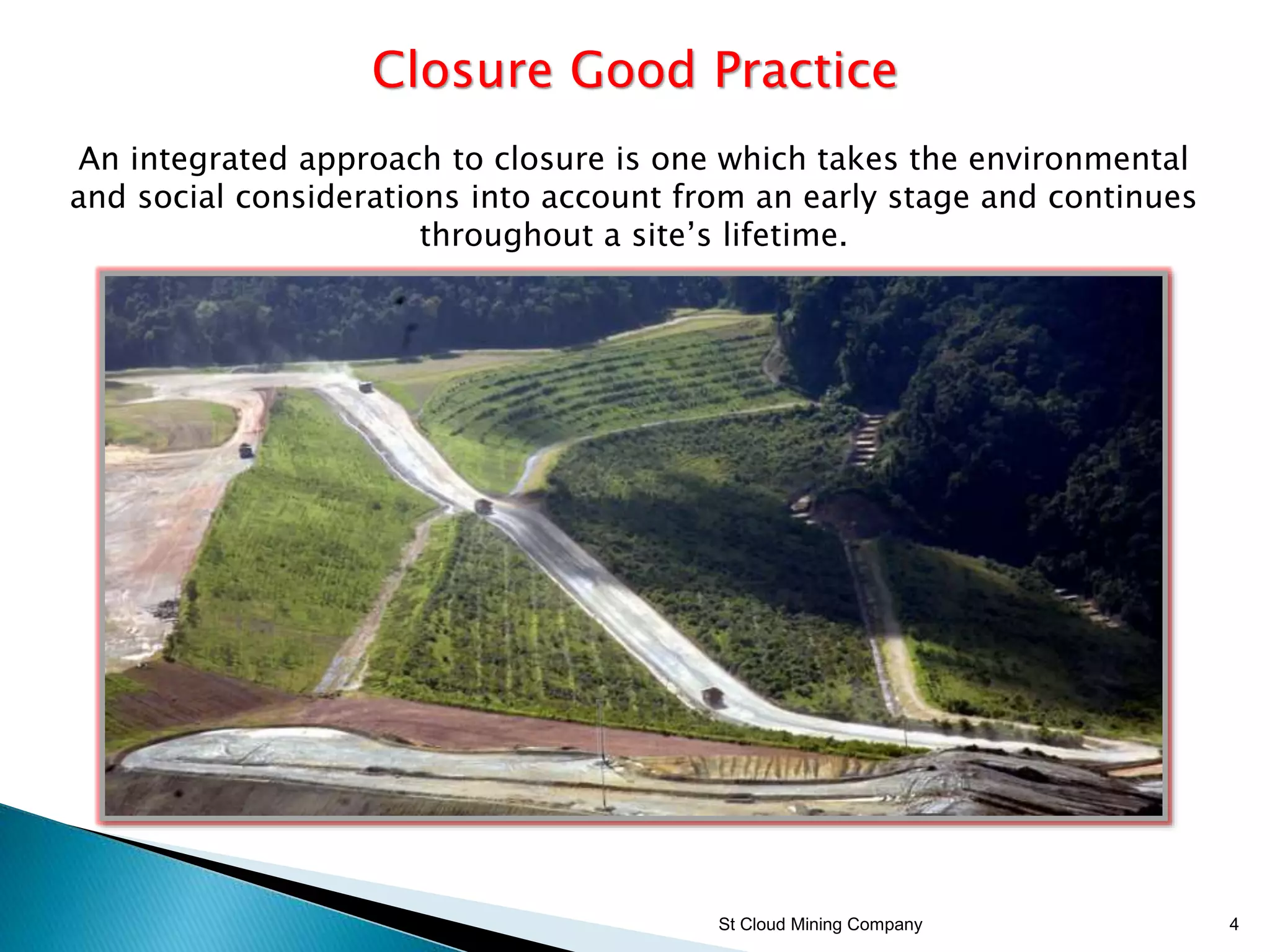

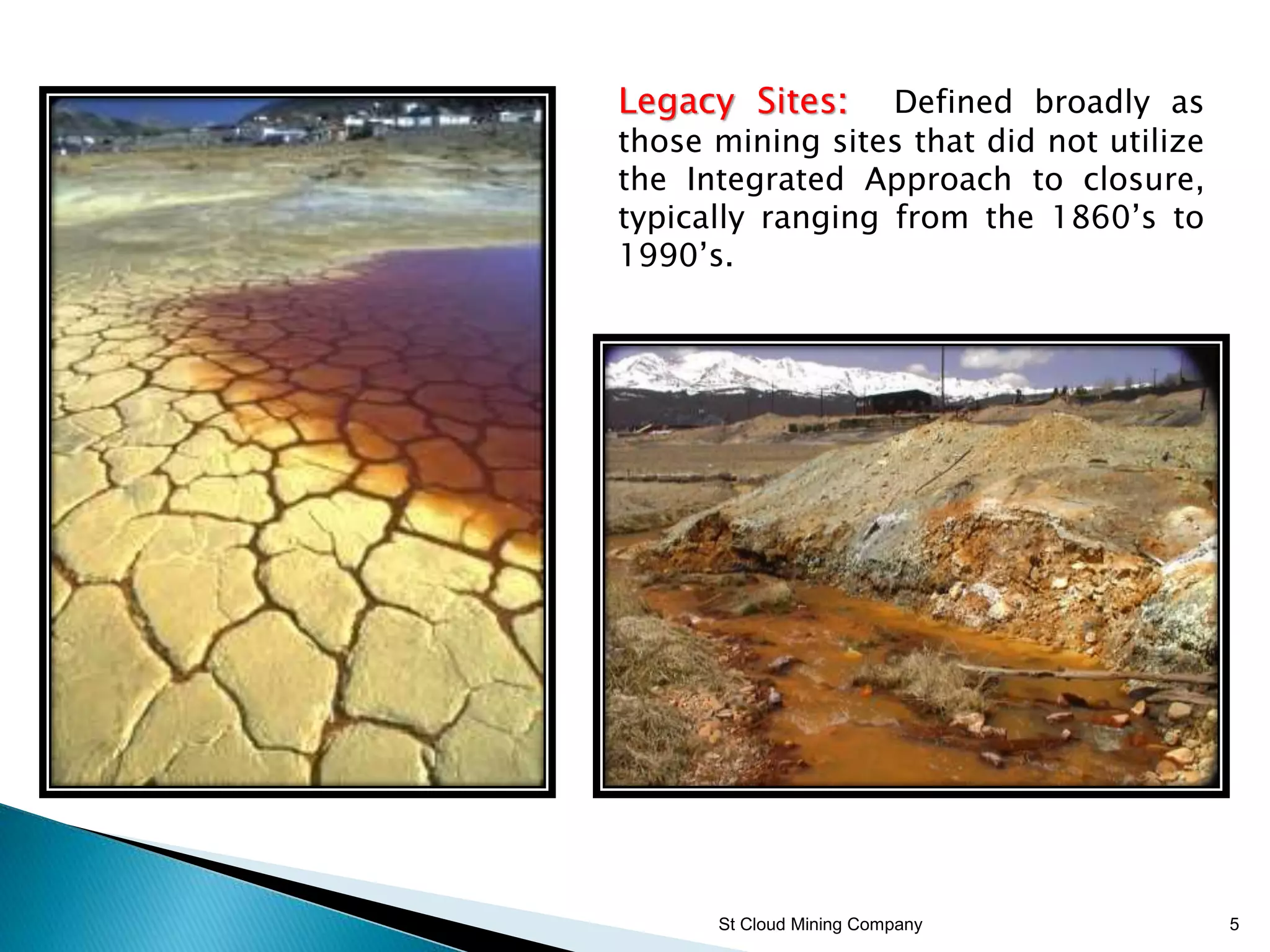

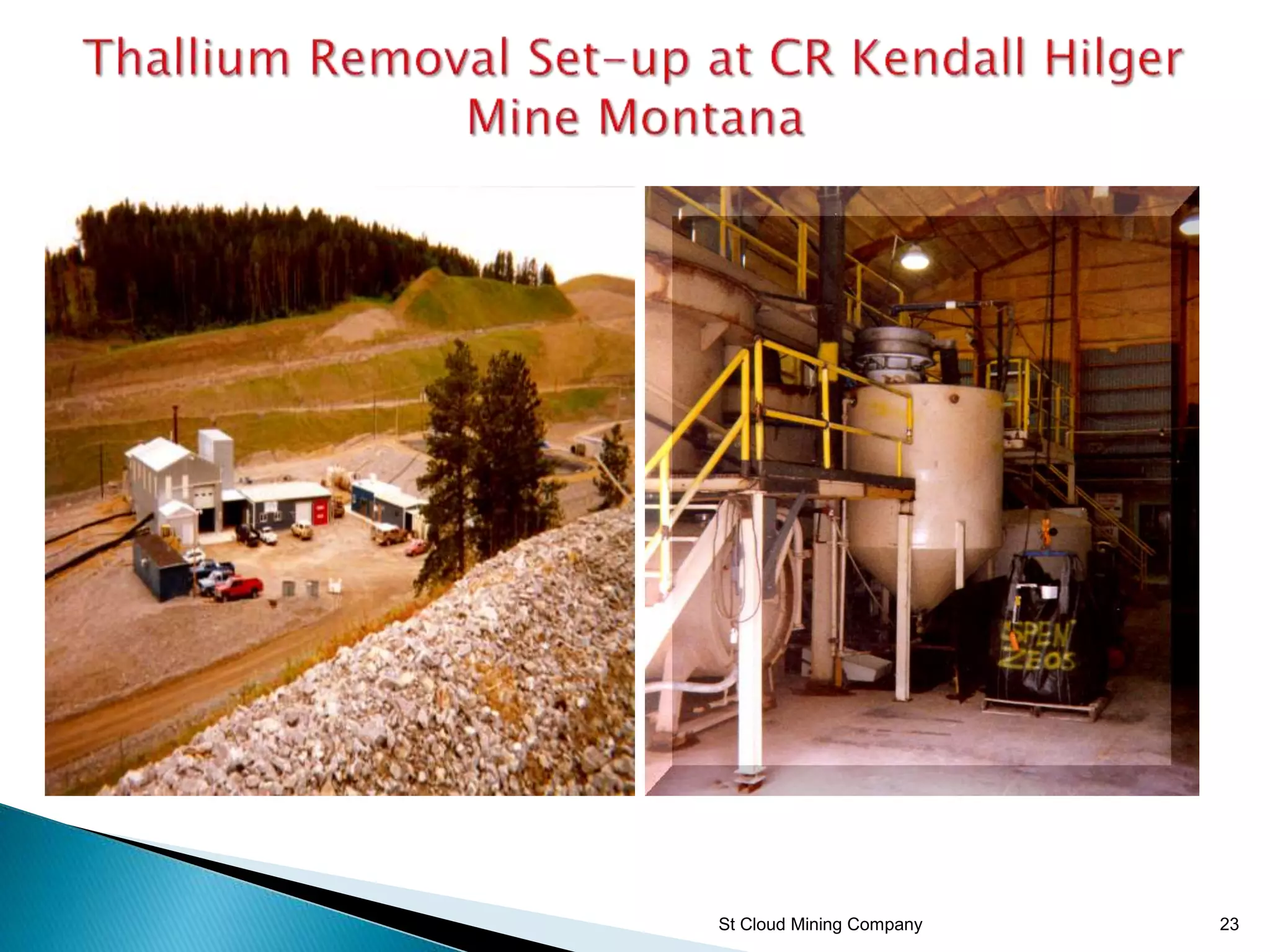

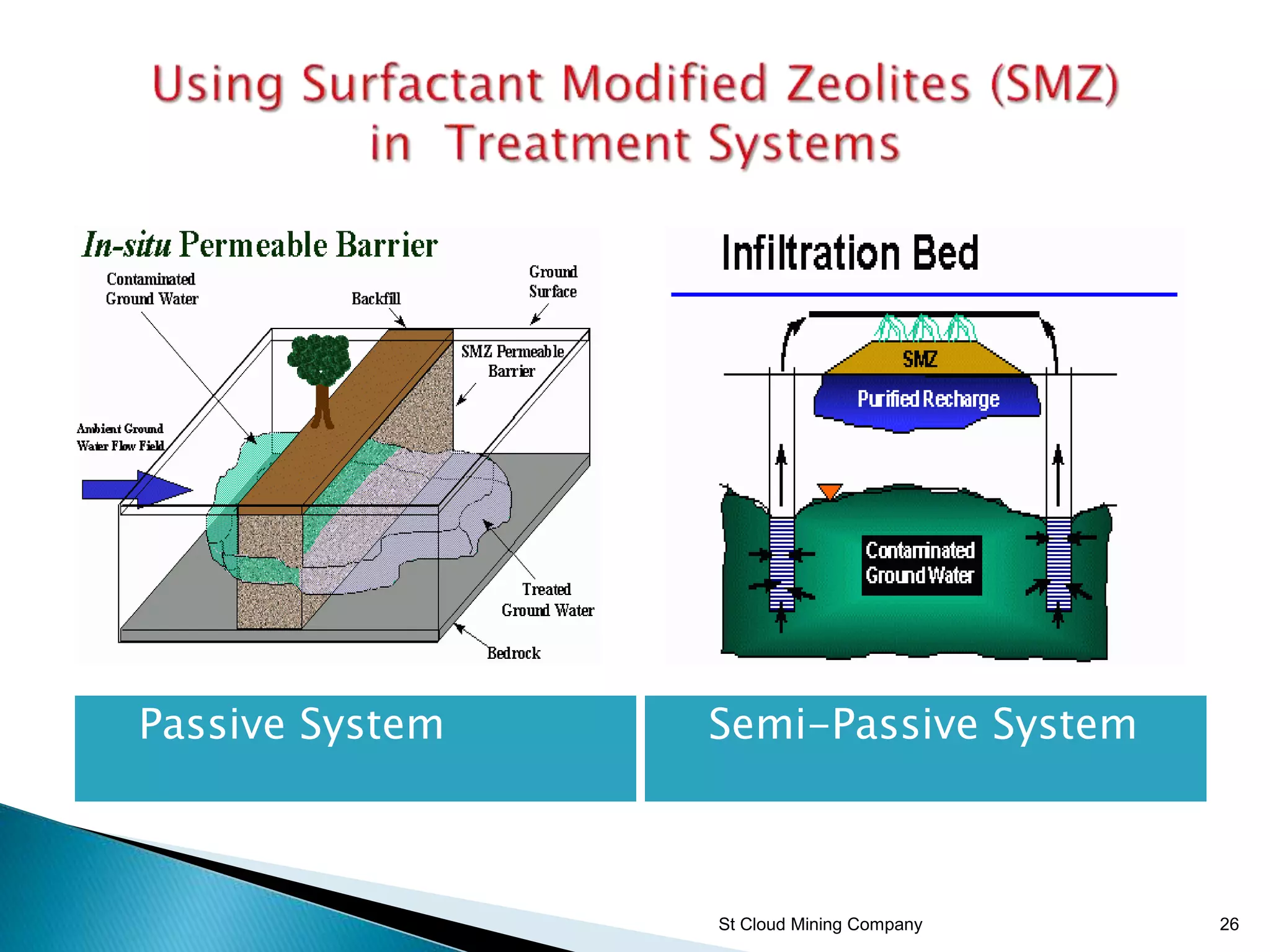

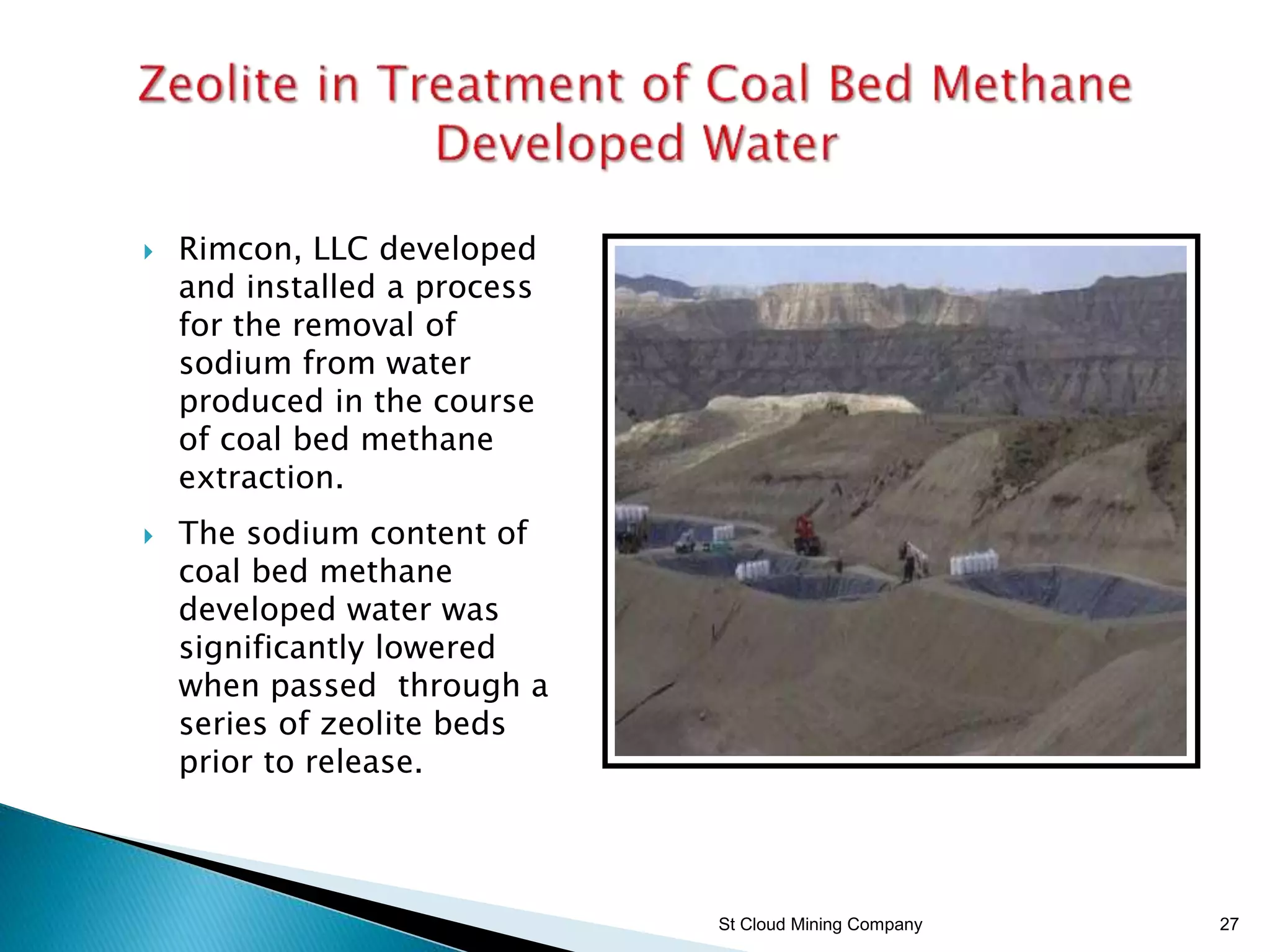

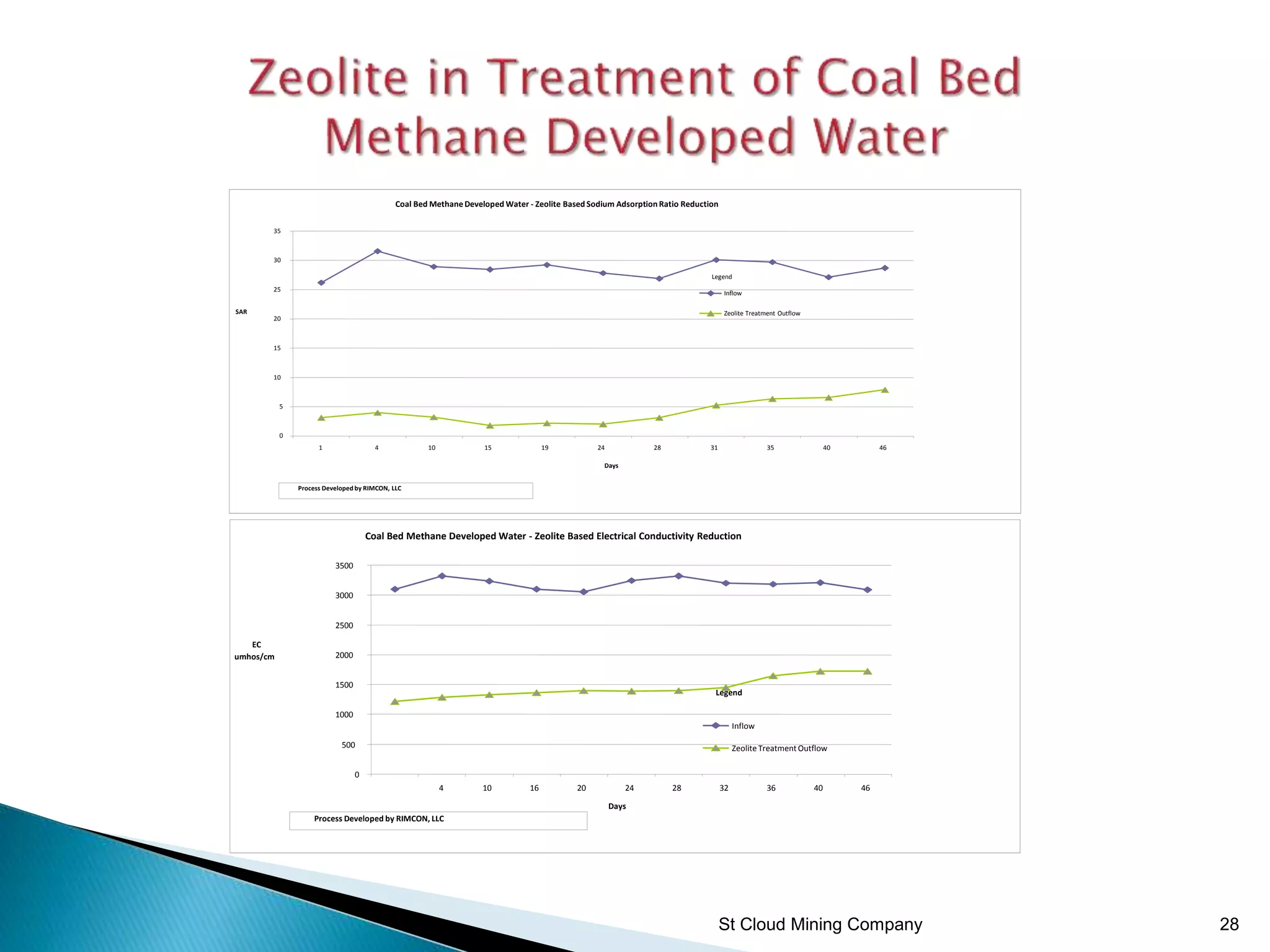

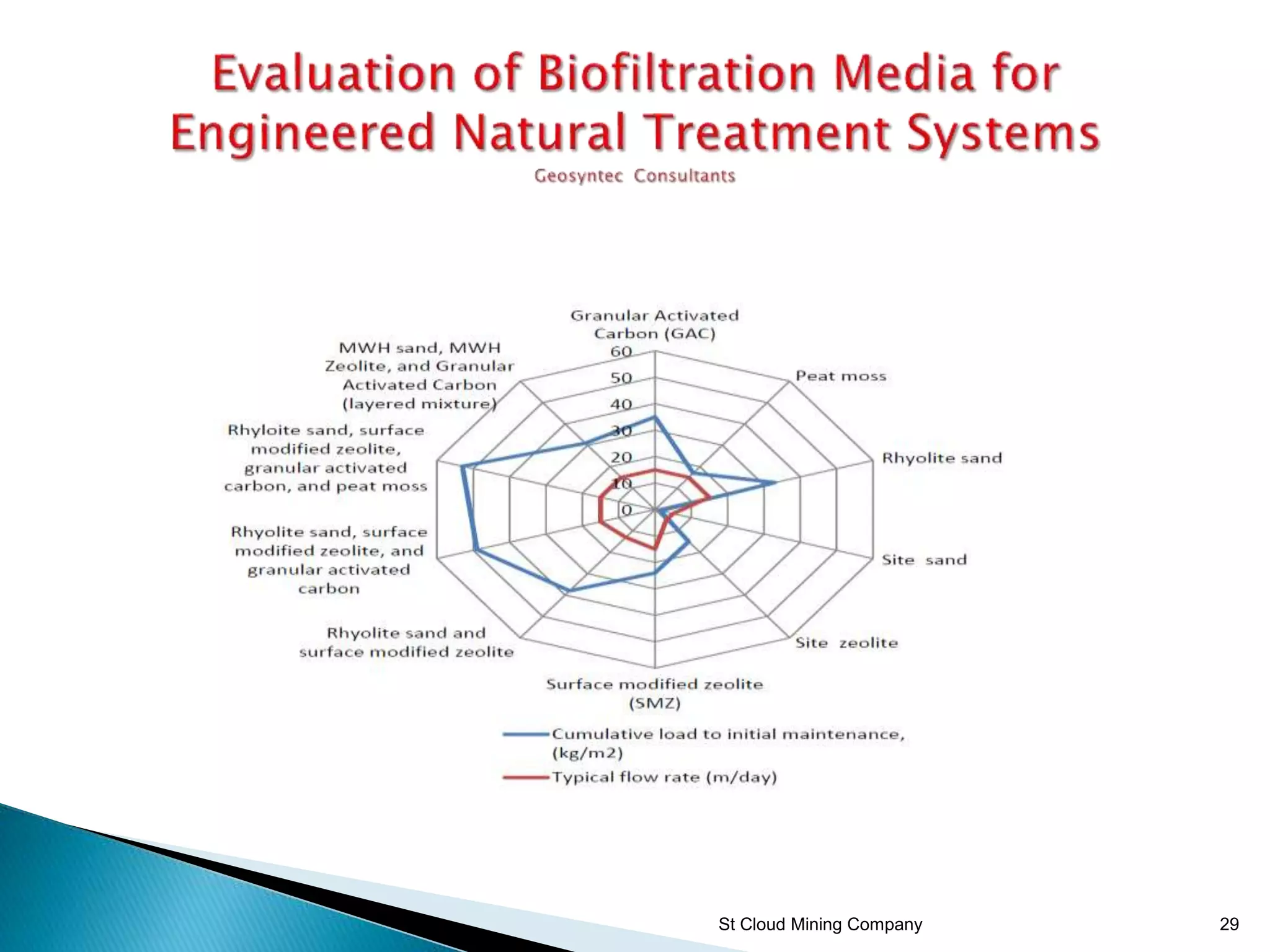

The document outlines the financial threats and environmental impacts associated with legacy mining sites that did not utilize an integrated approach to closure. It discusses various strategies for water management, treatment technologies, and the importance of community perspectives and legal compliance in mitigating contamination risks. Various water treatment products, particularly those utilizing natural zeolites, are presented as cost-effective solutions for treating mining and industrial waste water.