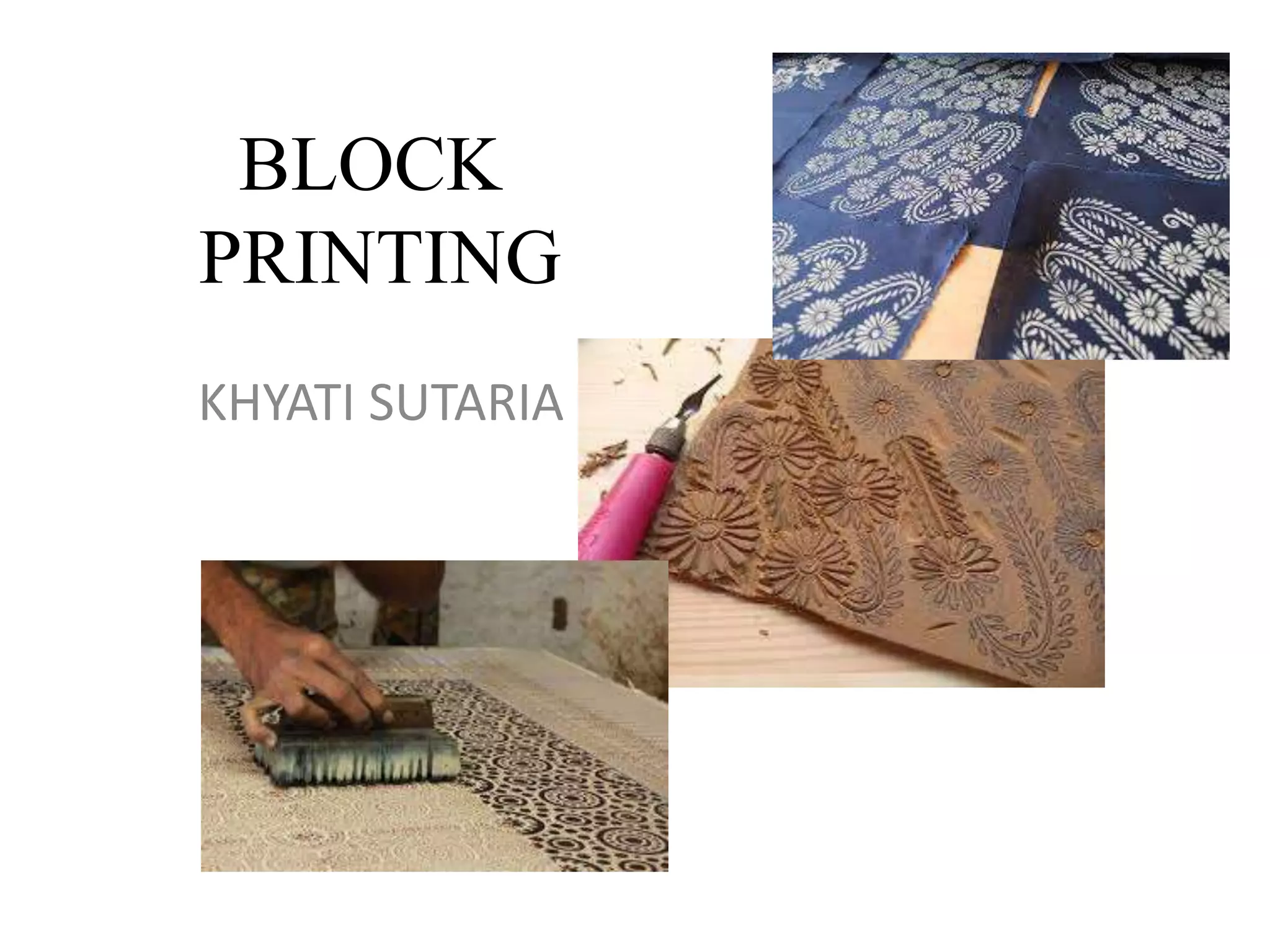

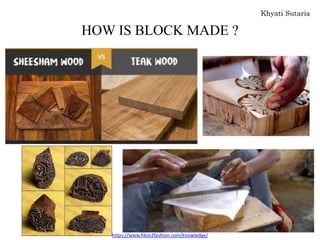

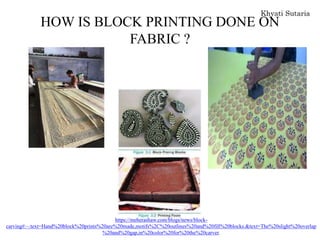

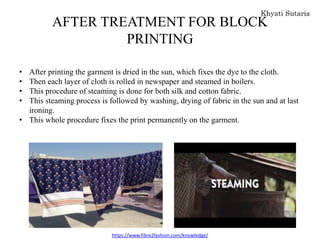

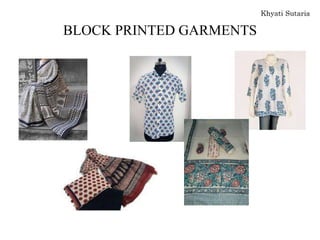

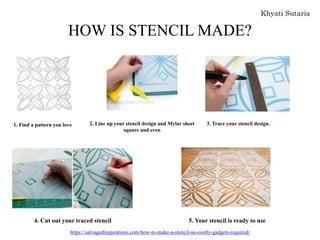

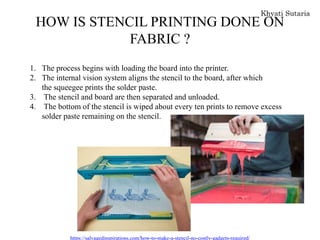

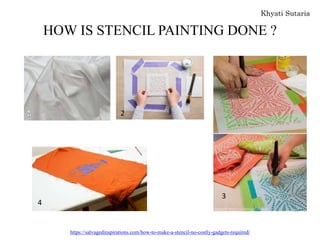

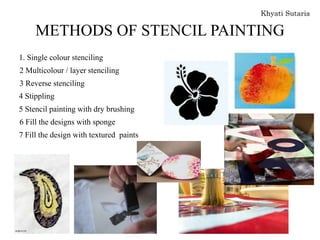

Block printing and stencil printing are traditional methods for applying designs to fabric in India. In block printing, carved wooden blocks are used to apply color in distinct patterns. There are regional variations in block printing styles based on background color. Stencil printing involves cutting a design template out of a thin material and applying color through the openings. Stencils must be designed so pieces do not fall out, requiring ties between separated areas. Both methods can produce varied and intricate patterns through manual application of dyes or paints in repeatable ways.