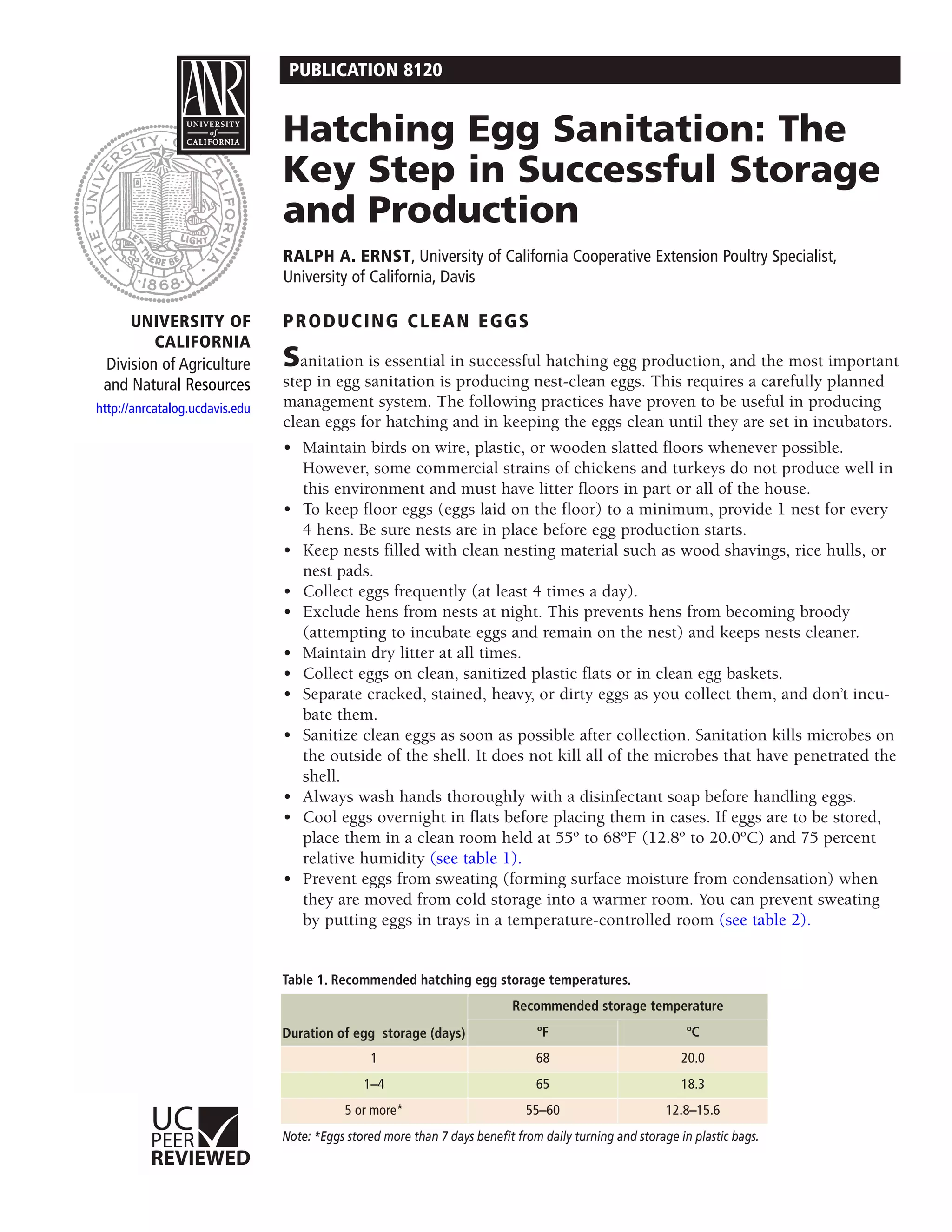

Sanitation is the most important step in producing clean hatching eggs. Proper management practices such as frequent egg collection, clean nesting materials, and separating dirty eggs are essential. Eggs should be sanitized soon after collection using approved methods like spraying or washing with disinfectants. Eggs must then be stored at regulated temperatures and humidity to prevent sweating or spoilage until incubation. Maintaining strict sanitation standards throughout the hatching egg production process is key to successful incubation and chick development.