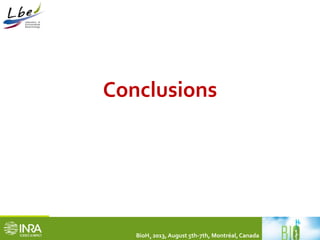

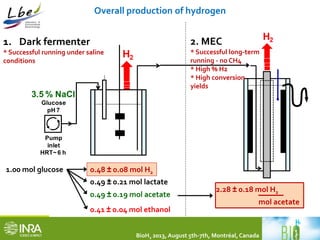

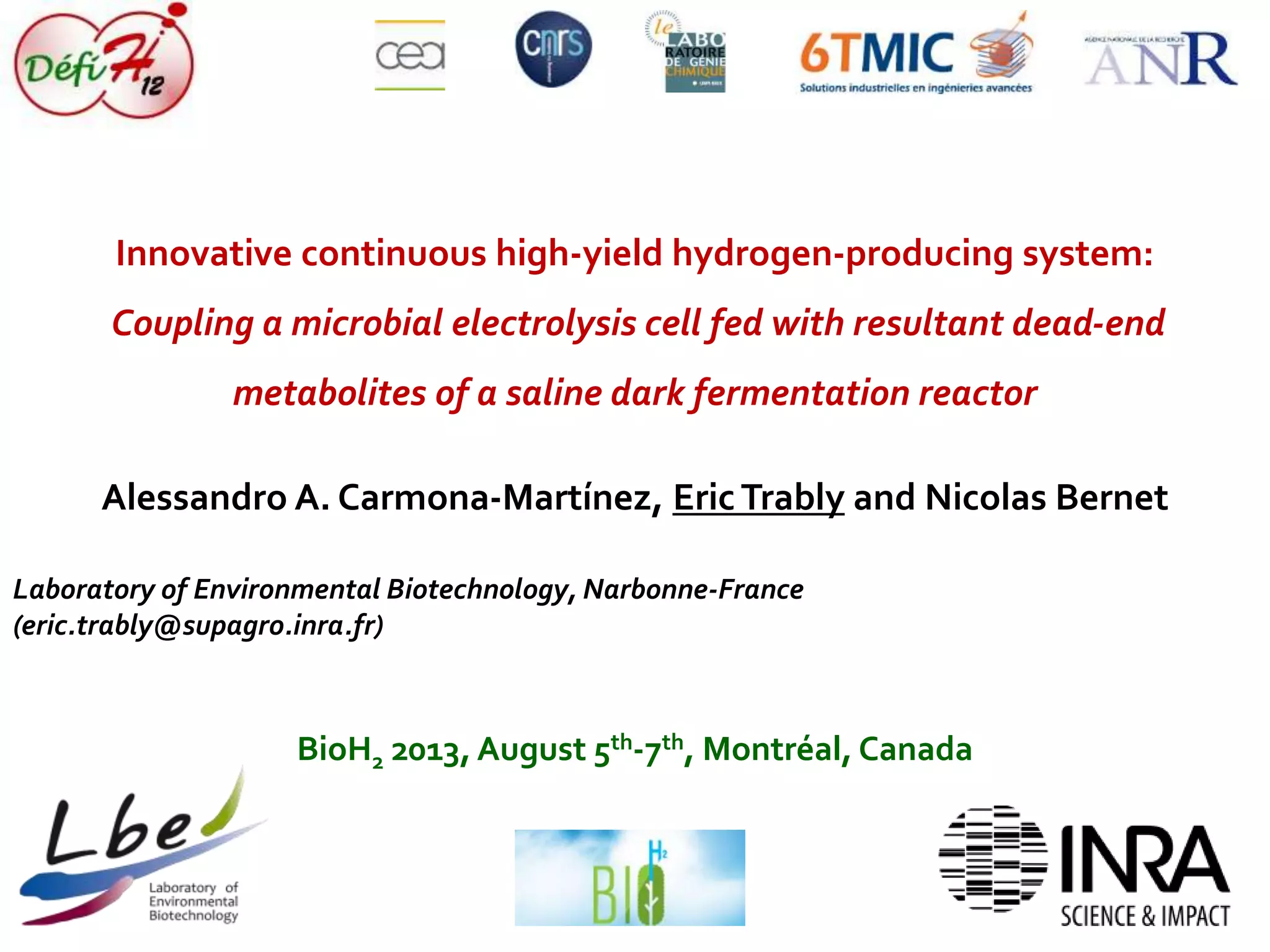

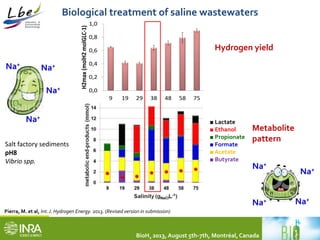

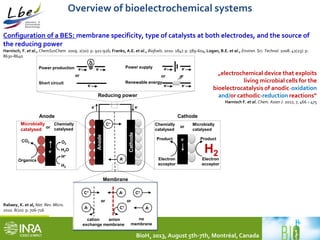

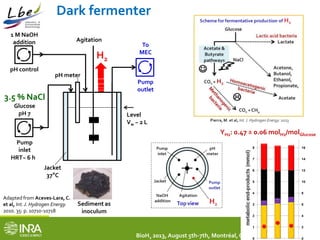

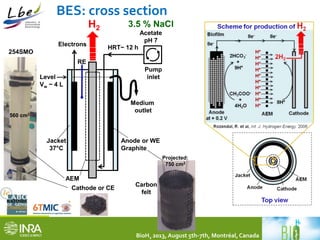

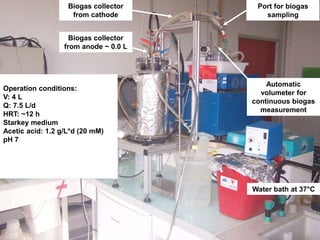

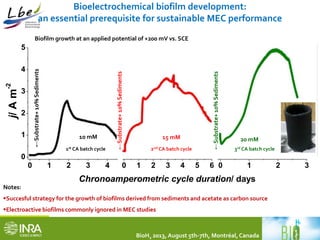

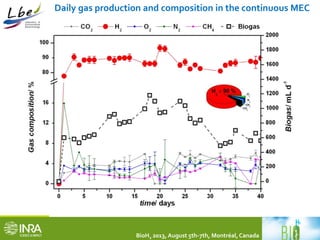

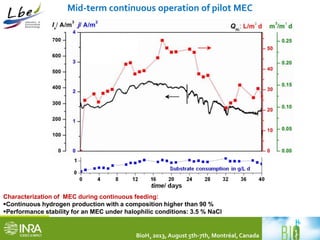

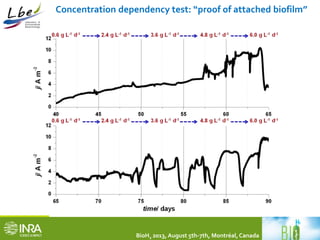

This document summarizes a study coupling a microbial electrolysis cell (MEC) to a dark fermentation reactor for continuous hydrogen production. A saline dark fermenter converted glucose into organic acids like acetate. The MEC was fed these metabolites and produced hydrogen gas at over 90% purity with a conversion rate of 2.28 moles of hydrogen per mole of acetate. Overall, the coupled system achieved 0.48 moles of hydrogen per mole of glucose initially fed to the dark fermenter and maintained stable performance over several weeks of continuous operation under saline conditions.

![Continuous high yield hydrogen gas production coupling system:

Dark fermenter → Microbial electrolysis cell

H2 H2

Dark

fermentation

Microbial

electrolysis

Any substrate Organic acids

(acetate,…)

BioH2 2013, August 5th-7th, Montréal, Canada

Outlet

Saline media

pH [7-8]](https://image.slidesharecdn.com/id-2318471-carmonatrablyfinal-141016120020-conversion-gate02/85/BioH2Conference-Alessandro-Carmona-2-320.jpg)

![MEC performances in comparison to other MEC studies

BioH2 2013, August 5th-7th, Montréal, Canada

Eapp./

V

Anode

material

T/

C

VMEC/

L

IA/

A m-2

Iv/

A m-3

Q/

L d-1

CE/ % YH2/

mol mol-1

QH2 /

m3 m-3 d-1

H2/

%

HRT/

h

Ref.

+0.2 Graphite

felt

37 4.00 2-3 400 7.5 22 2.28 0.15 ~90 12 This

work

-0.2 Graphite

brush

30 0.03 0.02 147 0.03 81 N.F. 3.6 68 24 [1]

+0.9 Graphite

brush

30 2.50 1.18 74 2.5 ˃100 N.F. 0.53 70 24 [2]

+0.8 Graphite

felt

28 0.20 2.91 40 N.F. 52 2.1 0.05 96.6 N.F. [3]

+1.5 Graphite

fiber

32 0.13 N.F. 1630 0.46 ˃100 2.0 4.3 53 6.5 [4]

+1.0 Graphite

felt

30 0.28 16.4 732 7.2 60 N.F. 5.6 N.F. 48 [5]

+1.2 Graphite

felt

30 0.05 6.00 0.6 0.008 N.F. 3.36 5.4 N.F. 6 [6]

[1] Nam et al. 2011, [2] Rader et al. 2010, [3] Chae et al. 2008, [4] Lee et al. 2010, [5] Sleutels et al., 2009, [6] Hrapovic et al., 2010

Notes:

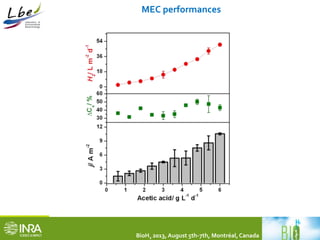

•All values are well in line with previous literature data

•However, just a very few studies have reported the coupling of dark fermentation and MEC technology

•So far, theMEC using acetate as a model metabolite shows a stable performance

•Not enough available information onMECs under saline conditions](https://image.slidesharecdn.com/id-2318471-carmonatrablyfinal-141016120020-conversion-gate02/85/BioH2Conference-Alessandro-Carmona-18-320.jpg)