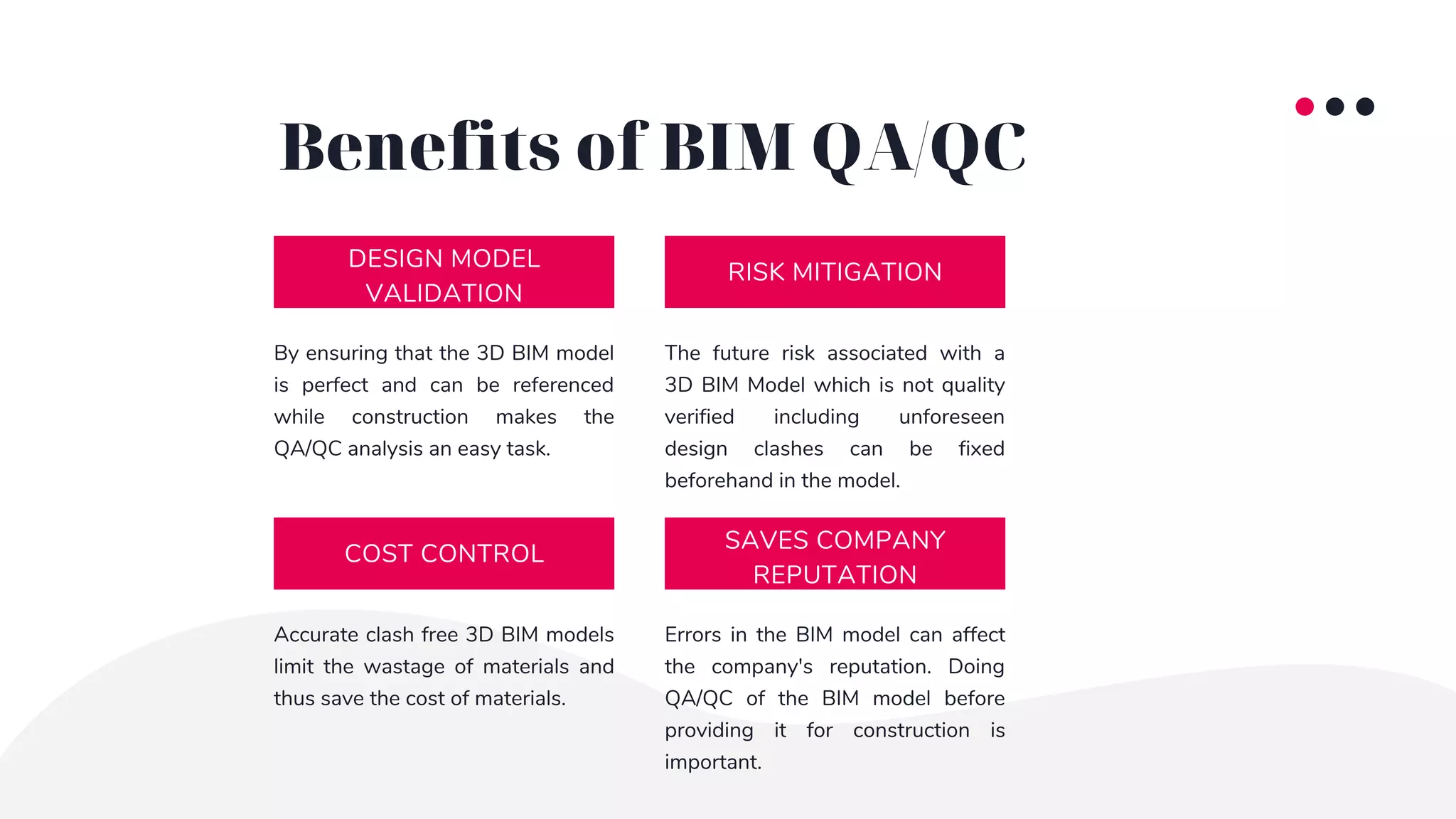

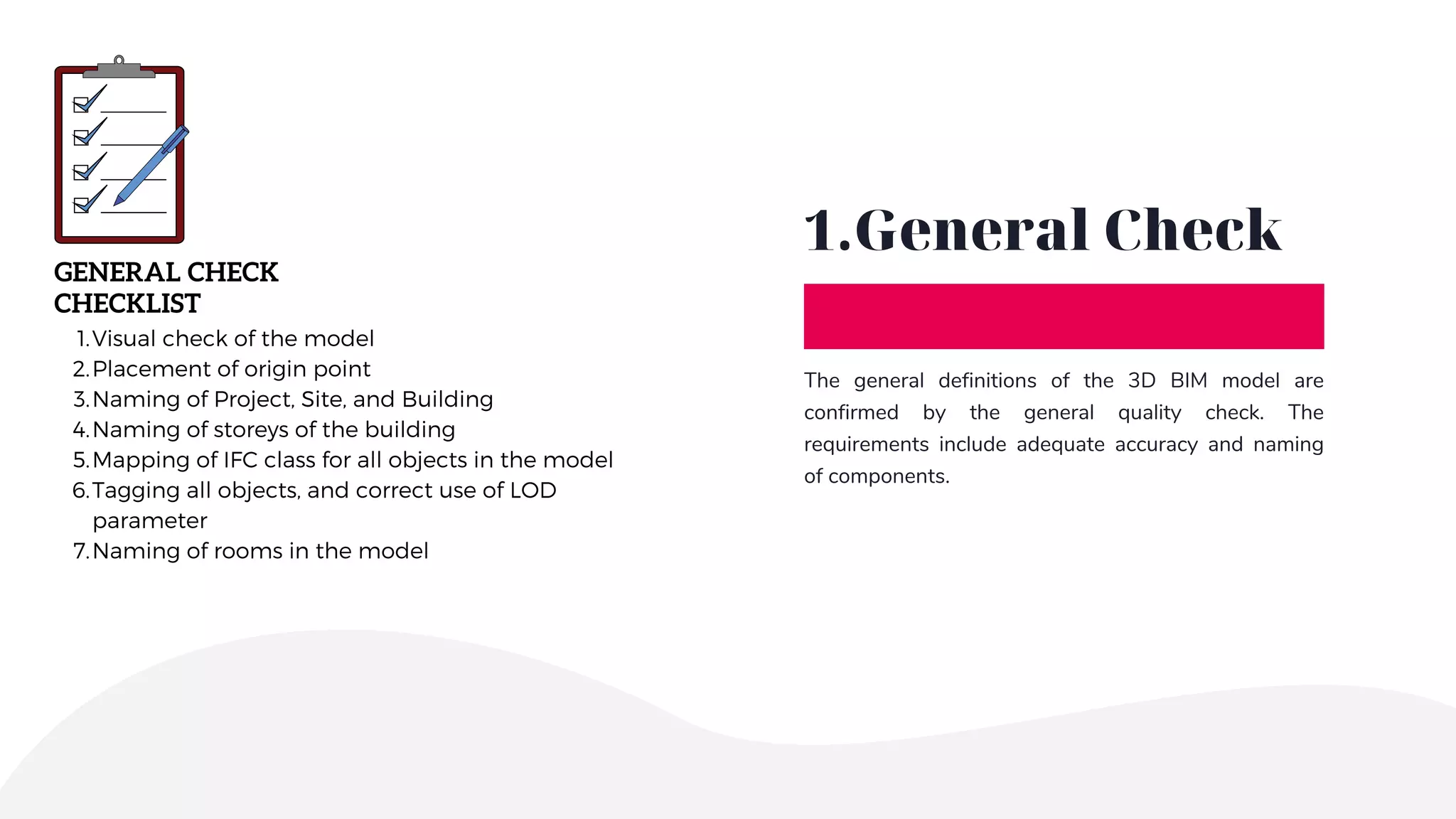

The BIM Quality Assurance and Validation Checklist is a tool to ensure that BIM models comply with standards and are free of errors before construction. It outlines various checks including general, space, design, MEP, and construction criteria, aimed at mitigating risks and maintaining the company's reputation. Utilizing software like Solibri Model Checker can streamline the QA/QC process and help deliver a coordinated BIM model for construction.