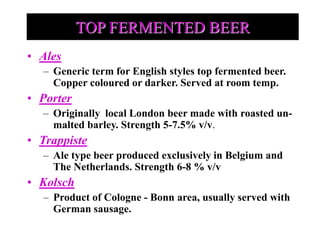

The document provides a history of beer, beginning with its origins in Mesopotamia over 5000 years ago. It discusses the role of monasteries in nurturing brewing across Europe in the Middle Ages. The 19th century saw innovations like lagering and refrigeration that expanded brewing. It also details the brewing process, including the key ingredients of barley, hops, water and yeast, and the steps of malting, mashing, boiling, fermenting and conditioning beer. Classical beer styles include top-fermented ales and wheat beers as well as bottom-fermented lagers like pilsner, dunkel and vienna beers.