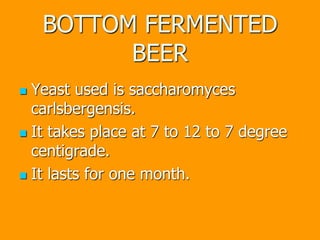

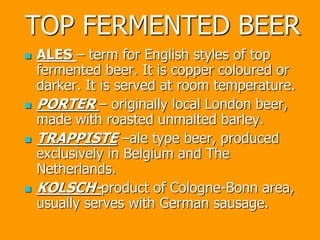

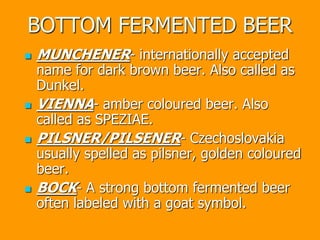

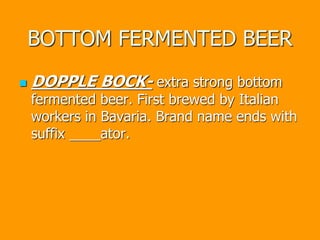

The document outlines the history, ingredients, and brewing process of beer, highlighting its origins and methods of production. Key ingredients include barley, water, hops, and yeast, each contributing to the characteristics of the final brew. Different brewing techniques and styles, including fermentation processes and beer types, are also described.