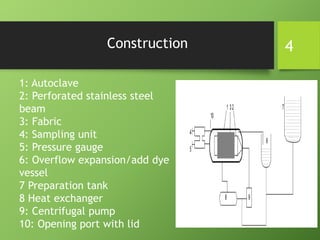

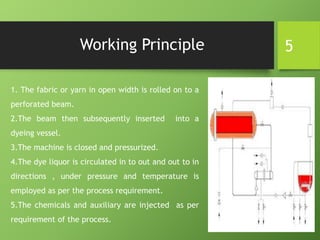

The document presents a study on beam dyeing machines, detailing their construction, working principles, and maintenance requirements. Beam dyeing is described as an economical method similar to package dyeing, utilizing a perforated beam for dyeing fabric in an open width. Maintenance guidelines emphasize regular cleaning, checking of components, and ensuring optimal operation to manage water and energy consumption.