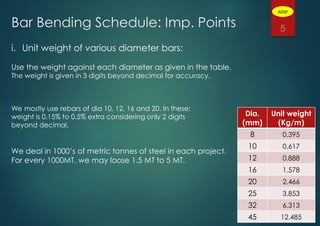

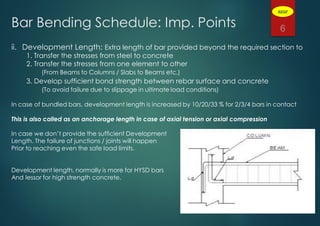

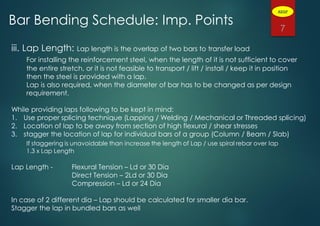

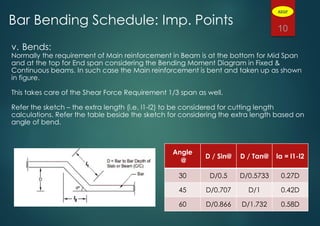

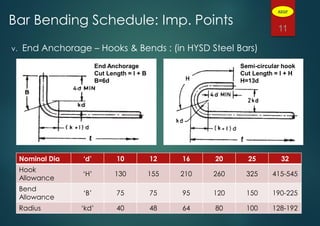

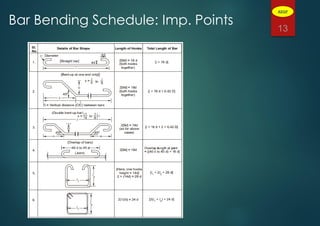

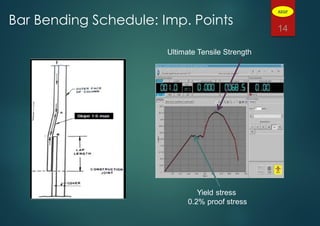

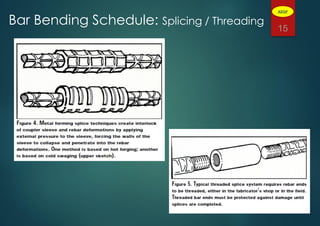

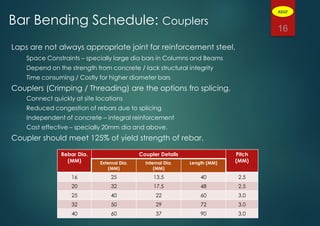

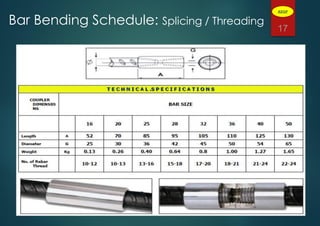

The document discusses key points about preparing a bar bending schedule (BBS), including defining what a BBS is, the process for preparing one, and important considerations. Some key points covered include calculating bar numbers and cut lengths, factors that influence lap and development lengths, approved bend angles and their allowances, and splicing options like couplers that can be used instead of lapping bars. The document provides guidance on accurately estimating rebar quantities and cutting costs based on the BBS.