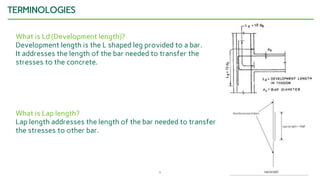

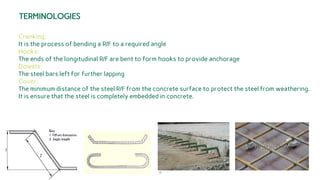

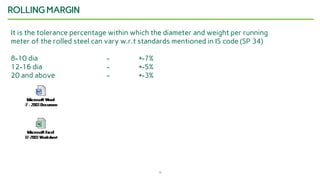

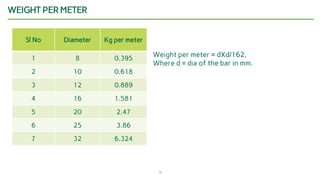

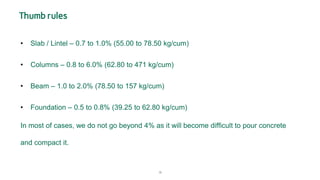

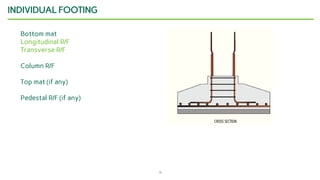

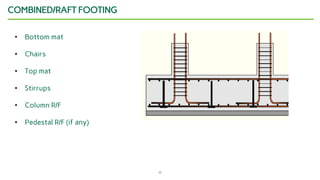

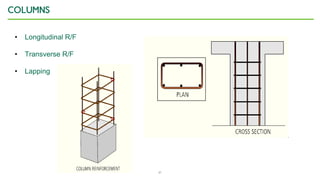

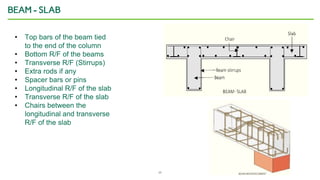

This document provides information about steel reinforcement bars including terminology, types of steel bars, bending schedules, and design considerations. It discusses the components of steel, differences between steel and iron, grades of steel bars including Fe415, Fe500 and Fe550, and types of steel bars like TMT and CTD. It also provides bending schedules for elements like footings, columns, beams and slabs. Important points covered include lapping requirements, cover concrete thickness, binding wire usage, and steel wastage percentages.