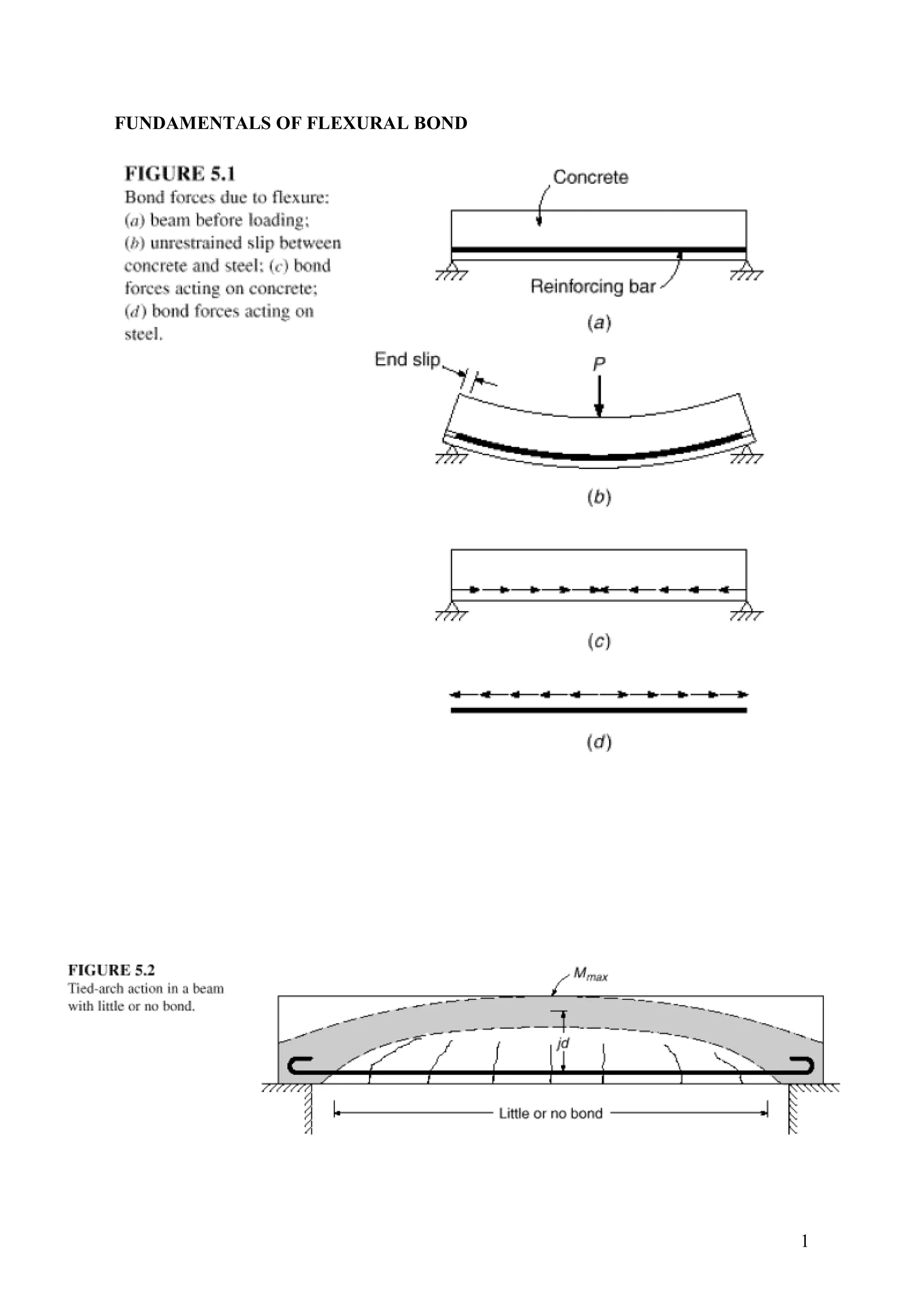

This document discusses fundamentals of flexural bond including:

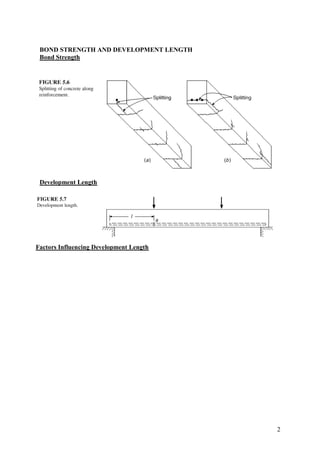

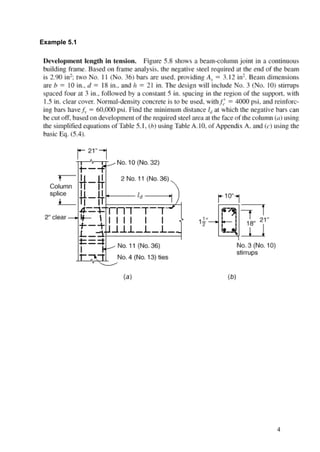

1. Bond strength and development length requirements for tension reinforcement according to the ACI code.

2. Simplified equations and factors that influence development length calculations.

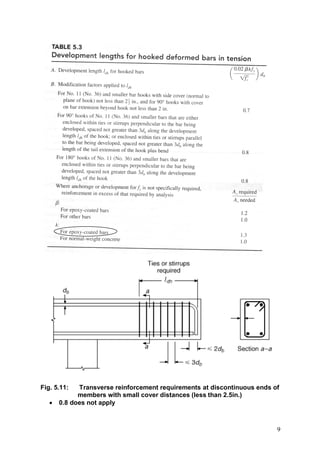

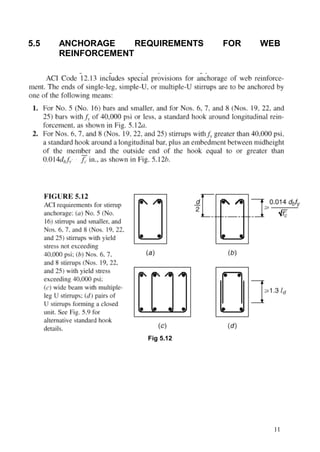

3. Anchorage requirements including standard dimensions for bar hooks, development lengths for hooked bars, and transverse reinforcement requirements.

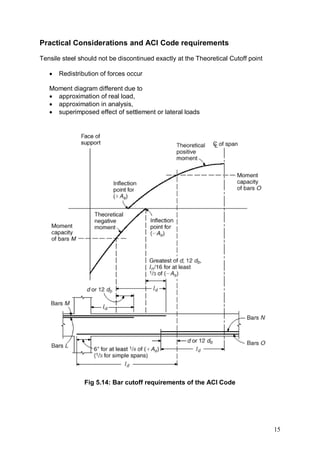

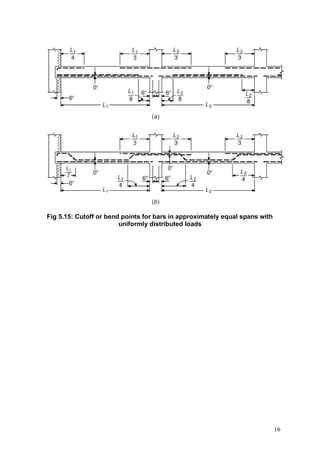

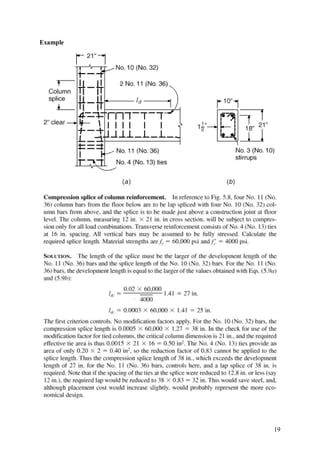

4. Additional topics on anchorage of web reinforcement, development bars in compression, bundled bars, bar cutoffs in beams, and bar splices. Diagrams and examples are provided to illustrate key concepts.