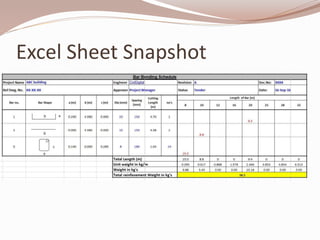

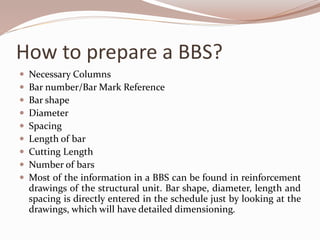

A Bar Bending Schedule (BBS) is a comprehensive list that describes the location, type, size, length, number and bending details of each reinforcement bar in a structure's Reinforcement Drawing. It organizes the rebar details for each structural unit and provides the necessary reinforcement requirements. The BBS is used by various professionals in the construction process, from ordering materials to installation. It includes columns for the bar mark, shape, diameter, spacing, length, cutting length, and number of bars. The information comes from the reinforcement drawings and standard calculations. The BBS helps ensure the correct reinforcement is fabricated and installed according to the design plans.

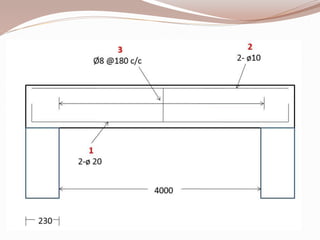

![ Number of bars:

Suppose the spacing of stirrups is 150 c/c and the

length along which they are placed is 6800 mm, we

can find the number of bars by the formula below

[ Length / Spacing ] + 1 = number of bars

[ 6800 / 150 ] + 1 = 46.33

In this case, we always round up. Hence, we require 47

stirrups.](https://image.slidesharecdn.com/bbsppt-230510065248-3e022d7a/85/BBS-ppt-pptx-10-320.jpg)