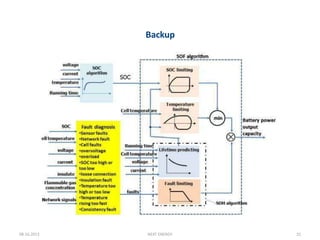

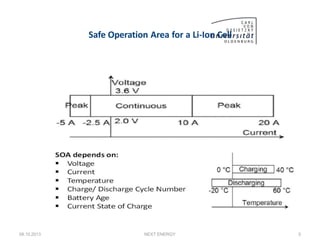

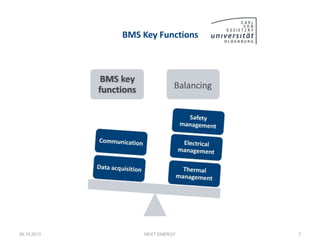

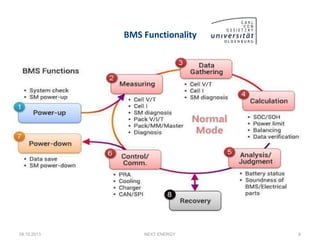

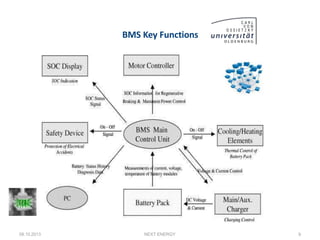

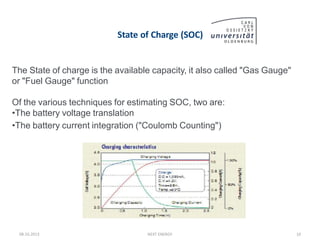

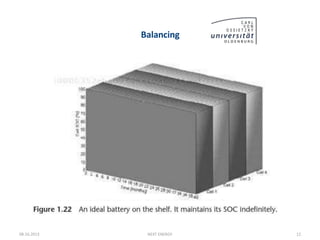

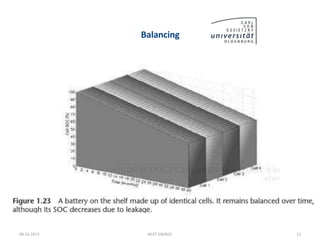

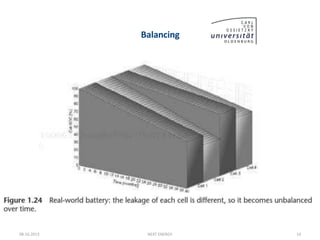

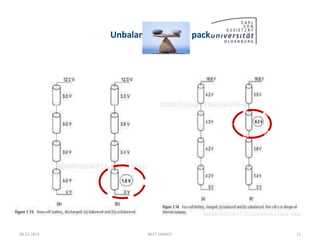

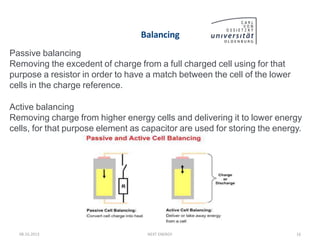

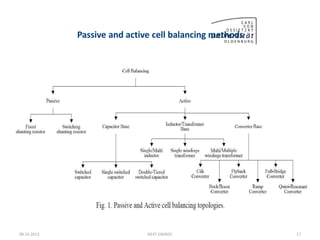

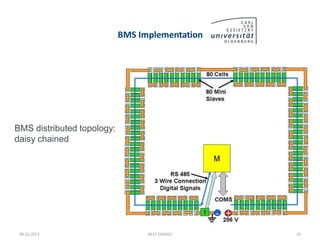

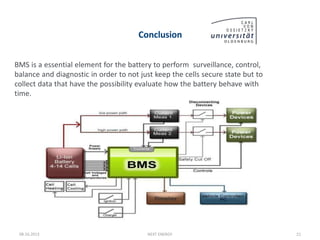

The document discusses battery management systems (BMS) and their key functions. A BMS is necessary to protect lithium-ion batteries and ensure their safe operation by monitoring factors like voltage, temperature, and state of charge. It aims to maximize battery life by balancing cells and tracking health over time. The BMS prevents damage by keeping the battery within a safe operating area and implements balancing techniques, like passive or active balancing, to equalize charges between cells.

![References

08.10.2013 NEXT ENERGY 22

[1]

[2]

Davide A. (2010): Battery Management Systems for Large Lithium Ion Battery Packs; Artech House, ISBN

1608071049

Speltino C. (2010): The Lithium-Ion Cell: Model State of Charge Estimation and Battery Management System;

Presentation at the University of Sannio Benevento

Lu l. et al. (2013) A review on the key issues for lithium-ion battery management in electric vehicles; Journal of

Power Sources 226 (2013) 272e288

Dai H. et al. (2012), A Hardware-in-the-Loop System for Development of Automotive Battery Management

System

Measuring Technology and Mechatronics Automation in Electrical Engineering Lecture Notes in Electrical

Engineering Volume 135, 2012, pp 27-36

Balakrishnan P. et al. (2006): Safety mechanisms in lithium-ion batteries; Journal of Power Sources 155

401– 414

Chiu P. et al. (2005): B#: a Battery Emulator and Power Profiling Instrument; IEEE Design & Test of

Computers March–April

Nec-Tokin (2009): Characteristics of Li-Ion Batteries; www.nec-tokin.com

Jossen A. et al. (2010) Reliable Battery Operation – A Challenge For the BMS; Journal of Power Sources

[3]

[4]

[5]

[6]

[7]

[8]](https://image.slidesharecdn.com/batterymanagementsystem-240118003506-b015509a/85/battery-management-system-ppt-22-320.jpg)