1) The document discusses the design of a hardware battery management system (BMS) for electric vehicles and energy storage.

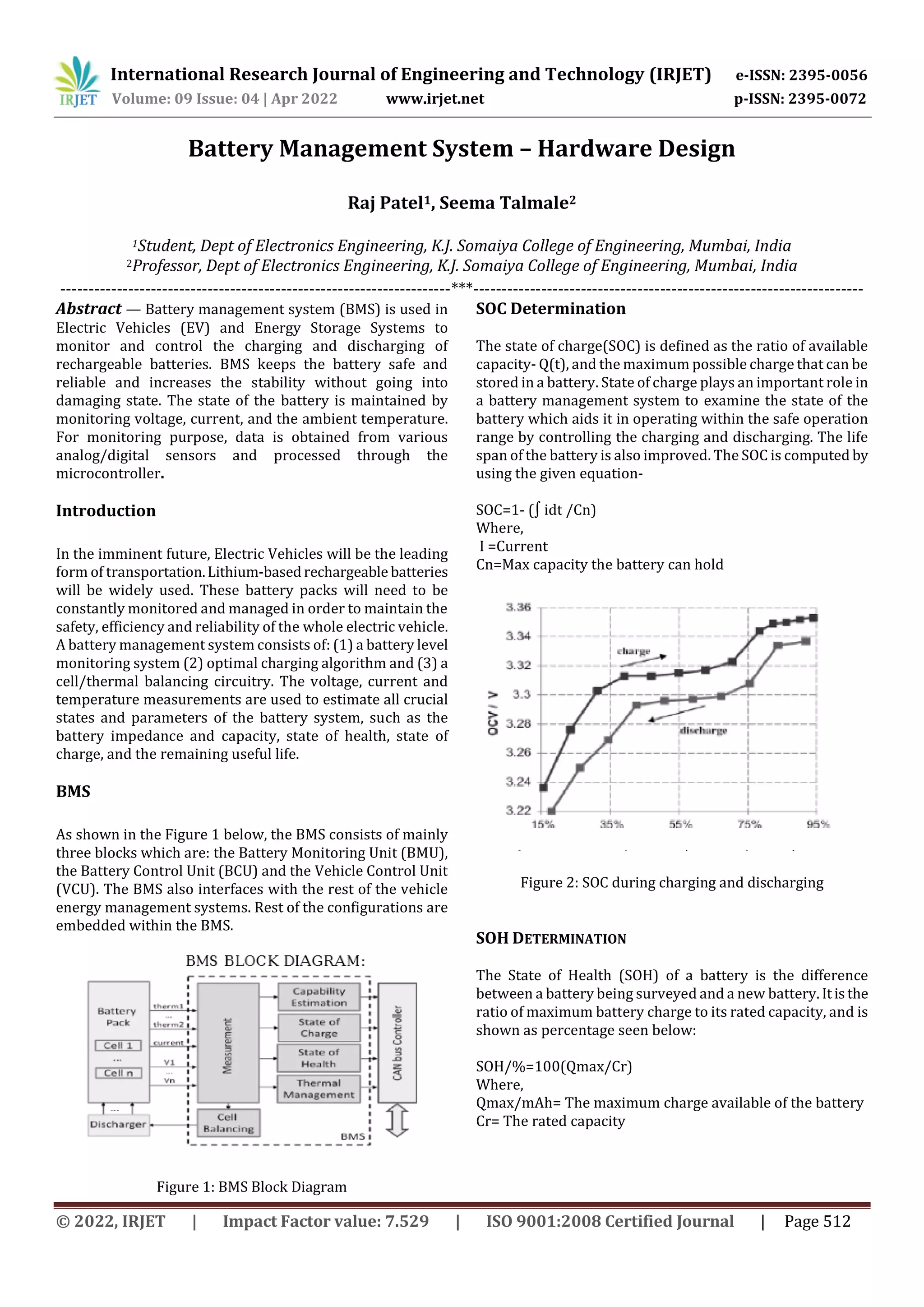

2) A BMS monitors and controls batteries by measuring voltage, current, and temperature to keep batteries safe, efficient, and reliable.

3) The proposed BMS design uses a microcontroller-based master board to communicate with battery monitoring and balancing boards via CANBUS, measuring cell voltages and temperatures to determine state of charge and health and enable thermal management.